Closed Loop Stepper Motor Producer

Top sponsor listing

Top sponsor listing

1/17

1/17

1/44

1/44

1/11

1/11

1/3

1/3

1/16

1/16

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

1/18

1/18

1/9

1/9

1/36

1/36

1/3

1/3

1/3

1/3

1/24

1/24

1/3

1/3

1/3

1/3

About closed loop stepper motor producer

Where to Find Closed Loop Stepper Motor Producers?

China remains the central hub for closed loop stepper motor production, with key manufacturing clusters concentrated in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated facilities that combine precision machining, coil winding, magnet assembly, and driver integration under one roof. Suppliers in Lishui (Zhejiang) and Changzhou (Jiangsu) leverage localized supply chains for rare-earth magnets and laminated steel cores, reducing component procurement lead times by 20–30% compared to offshore alternatives.

The industrial ecosystem supports both high-volume OEM output and low-volume custom engineering. Facilities typically operate automated stator winding lines and laser-welded rotor assemblies, enabling consistent torque performance across batches. Most producers maintain in-house testing labs for thermal endurance, insulation resistance, and step accuracy validation. Buyers benefit from scalable production models—standard NEMA 23 and NEMA 34 motors are available with lead times of 15–25 days, while customized configurations (e.g., IP65 sealing, encoder integration) require 30–45 days depending on complexity.

How to Choose Closed Loop Stepper Motor Producers?

Evaluate suppliers using these technical and operational benchmarks:

Production Infrastructure Verification

Confirm ownership of core production processes: CNC machining for housings, automated coil winding, dynamic balancing, and final calibration. Prioritize manufacturers with dedicated R&D teams capable of modifying phase current, step angle (0.9°–1.8°), or shaft configuration. Minimum facility size should exceed 2,000m² to ensure batch consistency and inventory buffer capacity.

Quality Assurance Protocols

While formal ISO 9001 certification is not explicitly listed in available data, on-time delivery rates above 95% and reorder rates below 15% indicate stable quality control. Look for evidence of 100% end-of-line testing for insulation resistance (>100MΩ at 500VDC), no-load current draw, and incremental torque linearity. CE or RoHS compliance should be confirmed for export-bound orders targeting EU or North American markets.

Customization & Transaction Security

Leading producers offer configurable parameters including:

- Shaft type (round, D-cut, keyway), length, and diameter

- Color coding for windings or housing

- Integrated gearboxes with reduction ratios from 3:1 to 100:1

- Labeling, branding, and packaging modifications

Use milestone-based payment terms with partial release upon sample approval. Request test reports for dielectric strength and temperature rise before full dispatch. Validate response time consistency (target ≤2 hours) as an indicator of post-sales support reliability.

What Are the Top Closed Loop Stepper Motor Producers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Scope | Min. Order Quantity | Verified Status |

|---|---|---|---|---|---|---|---|---|

| Lishui Hengli Automation Technology Co., Ltd. | Stepper Motors, Speed Reducers, Motor Drivers | 99% | ≤1h | <15% | US $420,000+ | Color, material, logo, packaging, label, graphic | 1 set | Custom Manufacturer |

| Changzhou Maples Precision Electromechanical Co., Ltd. | Hybrid Servo Motors, Closed-Loop Stepper Systems | 100% | ≤3h | 24% | US $300,000+ | Brake, cables, color, size, logo, packaging | 1–2 pieces | Multispecialty Supplier |

| Guangdong Kaihong Motor Co., Ltd. | Integrated Closed-Loop Kits, CNC Motor Packages | 96% | ≤3h | 30% | US $100,000+ | Shaft type, torque, gear box, step angle, power supply | 1 piece | Custom Manufacturer |

| Dongyang Lizhi Motor Co., Ltd. | NEMA 23/34 Closed-Loop Hybrid Steppers | 96% | ≤1h | <15% | US $20,000+ | Color, material, logo, packaging, graphic | 2 pieces | Multispecialty Supplier |

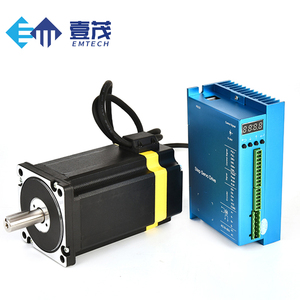

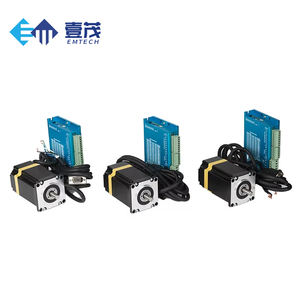

| Changzhou Emtech Intelligent Technology Co., Ltd. | AC Motors, Spindles, Speed Reducers | 95% | ≤2h | <15% | US $70,000+ | Torque, power, label, graphic, packaging | Not specified | Multispecialty Supplier |

Performance Analysis

Lishui Hengli stands out with a 99% on-time delivery rate and revenue exceeding US$420,000, indicating robust production planning and customer retention. Changzhou Maples achieves perfect punctuality (100%) despite higher reorder volume, suggesting efficient process control. Dongyang Lizhi and Lishui Hengli offer the fastest average response times (≤1h), critical for resolving technical queries during integration. Guangdong Kaihong’s 30% reorder rate reflects strong satisfaction among buyers requiring deep customization, particularly in CNC and automation sectors. All top-tier producers support single-unit sampling, lowering entry barriers for prototyping and small-batch validation.

FAQs

How to verify closed loop stepper motor producer reliability?

Request factory audit reports or video tours confirming in-house production lines for stator winding, rotor magnetization, and final calibration. Cross-reference claimed delivery performance with transaction history. Validate electrical specifications (rated current, inductance, back-EMF) against provided datasheets through independent lab testing.

What is the typical MOQ and lead time?

Standard MOQ ranges from 1 to 2 pieces for stock models, with bulk pricing activated at 20+ units. Lead time averages 15–25 days for unmodified motors. Custom variants with special shafts or encoders extend to 30–45 days. Air freight adds 5–7 days globally; sea shipping requires 25–35 days depending on destination port.

Can producers supply integrated driver-motor systems?

Yes, several manufacturers—including Guangdong Kaihong and Lishui Hengli—offer matched driver-motor kits with pre-tuned PID parameters. These integrated solutions reduce commissioning time in CNC, robotics, and automated dispensing applications. Confirm compatibility with pulse/direction or CANopen control interfaces prior to ordering.

Do suppliers provide free samples?

Sample policies vary. Some producers offer paid samples refundable against future orders (typically 50–100% credit). Free samples are uncommon but may be granted for high-potential partnerships involving monthly volumes exceeding 50 units. Expect sample costs between $20–$70 per unit depending on torque and integration level.

How to initiate motor customization?

Submit detailed requirements including holding torque (Nm), step angle, voltage range, shaft dimensions, IP rating, and feedback type (encoder PPR). Reputable producers respond with mechanical drawings within 48 hours and deliver functional prototypes within 3–4 weeks. For gearbox integration, specify reduction ratio, backlash tolerance, and output torque.