Stepper Motor With Reducer Supplier

Top sponsor listing

Top sponsor listing

1/1

1/1

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/29

1/29

1/11

1/11

1/24

1/24

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/11

1/11

1/3

1/3

1/26

1/26

1/13

1/13

About stepper motor with reducer supplier

Where to Find Stepper Motor with Reducer Suppliers?

China remains the central hub for stepper motor with reducer manufacturing, with key production clusters in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated supply chains combining precision machining, gear assembly, and motor winding capabilities within compact industrial zones. Shenzhen and Suzhou have emerged as innovation centers, offering advanced planetary gearbox integration and customized torque solutions for automation, robotics, and CNC equipment.

The ecosystem supports rapid prototyping and scalable production, with many suppliers operating automated assembly lines capable of producing 5,000–20,000 units monthly. Proximity to component manufacturers—such as rare-earth magnet producers and CNC gearbox fabricators—enables cost efficiencies of 15–25% compared to Western or Southeast Asian alternatives. Buyers benefit from short lead times (typically 15–30 days), flexible MOQs starting at 1–2 pieces, and access to engineering support for integration-specific modifications.

How to Choose Stepper Motor with Reducer Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm expertise in both stepper motor design and reducer integration. Ideal suppliers offer NEMA-standard frame sizes (NEMA 11, 17, 23, 28) with gear ratios from 1:1 to 1:100 and output torques up to 50 Nm. Validate compatibility with common drive systems (e.g., pulse/direction inputs) and thermal performance under continuous load. Suppliers listing over 100 motor variants typically maintain robust R&D and testing protocols.

Production & Quality Infrastructure

Assess operational scale and process control through the following indicators:

- On-time delivery rate exceeding 95%

- Response time under 4 hours for technical inquiries

- In-house testing for backlash, efficiency, and noise levels (≤60 dB typical)

- Evidence of quality management systems (e.g., ISO 9001 implied via consistent delivery metrics)

Suppliers with dedicated speed reducer listings often possess specialized gear inspection equipment, such as backlash analyzers and runout testers, ensuring tighter mechanical tolerances.

Procurement Risk Mitigation

Prioritize suppliers with transparent transaction histories and reorder rates below 15%, indicating broad customer acquisition rather than dependency on repeat clients. Use incremental ordering strategies—start with sample batches—to evaluate build consistency before scaling. Confirm packaging standards (e.g., anti-static, shock-resistant) for sensitive electromechanical components during international shipping.

What Are the Best Stepper Motor with Reducer Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Response Time | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|

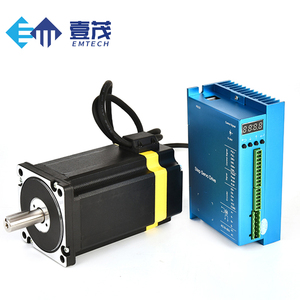

| Changzhou Emtech Intelligent Technology Co., Ltd. | Stepper Motors (665), AC Motors (157) | US $70,000+ | 95% | <15% | ≤2h | Color, size, logo, torque, packaging, power, graphics | Extensive stepper motor portfolio with integration-ready designs |

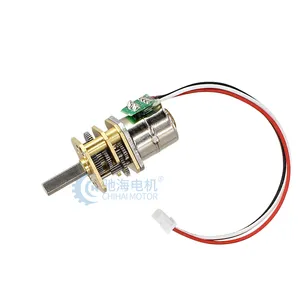

| Shenzhen Chihai Motor Co., Ltd. | DC Motors (540), Stepper Motors (77) | US $70,000+ | 100% | 15% | ≤4h | Limited public customization data | Broad DC focus with micro-stepper-reducer variants |

| Huizhou Dengfeng Technology Co., Ltd. | Other Electrical Equipment (1833), VFDs (404) | US $830,000+ | 100% | 33% | ≤2h | Not specified | High-power industrial reducers, likely SEW-compatible |

| Guangzhou Fude Electronic Technology Co., Ltd. | Stepper Motors (455), Linear Guides (12) | US $30,000+ | 71% | <15% | ≤6h | Not specified | NEMA 11–23 geared motors; mid-range torque applications |

| Ren Gong Mechanical Technology (Suzhou) Co., Ltd. | Speed Reducers (170), DC Motors (121) | US $10,000+ | 100% | <15% | ≤4h | Planetary reducer matching for servo/stepper systems | Specialized in high-precision planetary gearboxes |

Performance Analysis

Changzhou Emtech leads in product diversity and customization depth, making it suitable for OEMs requiring branded, application-specific motors. Shenzhen Chihai and Ren Gong stand out for perfect on-time delivery records and focused offerings—Chihai in micro-motor integration, Ren Gong in precision planetary reduction. Huizhou Dengfeng handles high-value industrial drives but exhibits a higher reorder rate (33%), suggesting niche market positioning. Guangzhou Fude offers competitive pricing but lags in delivery reliability (71%), warranting caution for time-sensitive projects.

FAQs

What is the typical MOQ for stepper motors with reducers?

MOQs range from 1 to 20 pieces depending on model and supplier. Many allow single-unit sampling, particularly for standard NEMA 17 or NEMA 23 configurations. High-torque or custom models may require minimum batches of 10–20 units.

How long does production and shipping take?

Lead times average 15–25 days for standard orders, including quality checks and packaging. Air freight adds 5–10 days for international delivery. Custom designs may extend timelines by 10–15 days for tooling and validation.

Can suppliers integrate specific gear ratios or shaft types?

Yes, several suppliers offer configurable gear ratios, output shaft diameters (e.g., M6, D-cut), and mounting flanges. Companies like Changzhou Emtech explicitly list shaft and torque customization, enabling drop-in replacements for legacy systems.

Are certifications like CE or RoHS available?

Certification details are not explicitly stated in public profiles. However, suppliers with consistent export histories and compliance-focused markets typically adhere to CE and RoHS standards. Request compliance documentation directly prior to order placement.

Do suppliers provide technical drawings and datasheets?

Most established suppliers offer downloadable specifications, including torque curves, dimensional prints, and wiring diagrams. For custom requests, expect 48–72 hour turnaround for revised mechanical drawings upon requirement submission.