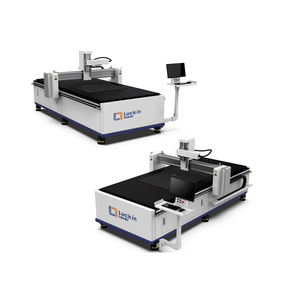

Cnc Advanced Technology

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About cnc advanced technology

Where to Find CNC Advanced Technology Suppliers?

China remains the global epicenter for advanced CNC machinery and precision machining services, with concentrated supplier clusters in Zhejiang, Guangdong, and Jiangsu provinces. These regions host vertically integrated manufacturing ecosystems that combine automated production lines, skilled technical labor, and proximity to raw material suppliers—enabling cost efficiencies of 20–35% compared to Western counterparts. Ningbo and Shenzhen serve as innovation hubs for high-precision CNC turning, milling, and multi-axis machining, while Jiangsu specializes in large-scale CNC lathes, milling centers, and gear hobbing systems.

The industrial clusters support rapid prototyping and scalable production through co-located component manufacturers, tooling specialists, and logistics networks. Facilities typically operate under ISO 9001-aligned quality management systems, with many offering CAD/CAM integration, real-time process monitoring, and smart factory-ready controls. Buyers benefit from lead times averaging 25–40 days for standard equipment and 30–50 days for custom machining orders, depending on complexity and order volume.

How to Choose CNC Advanced Technology Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Certifications

Verify compliance with international standards such as ISO 9001 for quality assurance. For export markets, confirm CE marking or equivalent safety certifications where applicable. Request documentation on machine accuracy (e.g., positioning repeatability ≤ ±0.01mm), spindle specifications, and controller types (Fanuc, Siemens, or equivalent). Suppliers should provide detailed CAD drawings, material traceability reports, and inspection records upon request.

Production Infrastructure Assessment

Evaluate core manufacturing attributes:

- Minimum facility size of 3,000m² for dedicated CNC workshops

- In-house capabilities covering turning, milling, grinding, and surface treatment processes

- Availability of multi-axis CNC machines (4-axis and above) for complex geometries

Cross-reference declared output capacity with verified on-time delivery performance (target ≥97%) and online revenue indicators to assess scalability and operational stability.

Customization & Quality Assurance Protocols

Confirm customization scope—including material options (aluminum, stainless steel, titanium, alloy steel), surface finishes (anodizing, plating, passivation), and branding (laser engraving, labeling). Prioritize suppliers offering pre-shipment inspection reports, first-article testing, and third-party quality audits. Use sample evaluations to validate dimensional accuracy, surface integrity, and functional performance before full-scale ordering.

What Are the Best CNC Advanced Technology Suppliers?

| Company Name | Location | Verified Supplier Type | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Key Offerings | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Ningbo Yizhong Hardware Products Co., Ltd. | Zhejiang, CN | Custom Manufacturer | 75% | ≤3h | 50% | US $10,000+ | Machining Services | titanium drawing |

| Shenzhen Ruichenxing Industry Co., Ltd. | Guangdong, CN | Custom Manufacturer | 100% | ≤1h | 37% | US $950,000+ | Precision CNC Machined Parts | Not specified |

| Wmt Cnc Industrial Co., Ltd. | Guangdong, CN | Custom Manufacturer | 97% | ≤4h | <15% | US $3,100,000+ | CNC Lathes, Milling Machines | color, packaging, label, CAD drawings, controller, spindle type, material, size, logo, chucks, tool turret, graphic, spindle table |

| Jiangsu Kingston Machine Tools Group Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | 100% | ≤2h | 100% | - | CK Series CNC Lathes, Gear Hobbing Machines | gear dia, color, material, size, module, logo, packaging, label, graphic |

| AVOS AUTO EXPORTS LIMITED | Unknown | Unknown | - | ≤4h | - | - | Haas VF-2 Milling Machine, TRUMPF Laser Cutters | Not specified |

Performance Analysis

Jiangsu Kingston Machine Tools Group stands out with a perfect 100% on-time delivery and reorder rate, indicating strong customer retention and production reliability despite unreported revenue. Shenzhen Ruichenxing matches this punctuality with sub-hour response times and significant digital sales volume (over US $950,000), suggesting robust operational efficiency. Wmt Cnc Industrial offers extensive customization across mechanical and aesthetic parameters, ideal for OEM integrations requiring brand-specific configurations. Ningbo Yizhong shows moderate delivery performance but maintains a high reorder rate (50%), reflecting niche expertise in titanium-based components. AVOS AUTO EXPORTS appears to resell branded industrial equipment, likely acting as a trading intermediary rather than a direct manufacturer.

FAQs

How to verify CNC advanced technology supplier reliability?

Validate certifications through issuing bodies and request facility audit reports or video tours confirming in-house machining capabilities. Analyze transaction metrics such as on-time delivery rates (>97% recommended), response speed, and verifiable customer feedback focusing on post-delivery support and defect resolution.

What is the typical MOQ and pricing structure?

For machined components, minimum order quantities start at 1 piece, with unit prices ranging from $0.33 for small metal parts to $6,000+ for complete CNC machine sets. Equipment suppliers typically require full-set orders (MOQ: 1 set), with pricing influenced by automation level, control system, and spindle power.

Are customization requests supported?

Yes, most manufacturers support technical and cosmetic customization. Common options include material selection, dimensional adjustments, surface treatments, controller configuration, and branding elements. Submit detailed specifications or 3D models early in negotiations to receive accurate quotations and feasibility assessments.

What are standard lead times for CNC machines and parts?

Lead time for customized CNC-machined parts averages 20–35 days, including sampling and approval cycles. For new CNC machine deliveries, expect 30–60 days depending on model complexity and factory workload. Expedited production may be available at additional cost.

Can suppliers handle international shipping?

Established manufacturers routinely export worldwide using FOB, CIF, or DDP terms. Confirm packaging standards (wooden crates, moisture protection), export documentation, and compliance with destination regulations for electrical and mechanical equipment. Sea freight is standard for heavy machinery, while air shipping applies to urgent spare parts or prototypes.