Machining And Cnc Technology

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About machining and cnc technology

Where to Find Machining and CNC Technology Suppliers?

China remains a central hub for machining and CNC technology manufacturing, with key supplier clusters in Shandong, Henan, Guangdong, and Zhejiang provinces. These regions host vertically integrated industrial ecosystems that support end-to-end production—from raw material sourcing to precision CNC machining and final assembly. Shandong and Guangdong are particularly notable for their concentration of advanced machining centers, offering scalable production capacity and rapid prototyping capabilities.

Suppliers in these zones benefit from proximity to steel, aluminum, and alloy suppliers, reducing input costs by 15–25% compared to non-integrated markets. Industrial parks often co-locate component manufacturers, tooling specialists, and logistics providers within 50km, enabling lead times as short as 15–30 days for custom-machined parts. Buyers gain access to high-volume output, multi-axis CNC processing (including 5-axis milling), and secondary operations such as sandblasting, anodizing, and automated lubrication system integration—all under one supply chain umbrella.

How to Choose Machining and CNC Technology Suppliers?

Selecting reliable partners requires structured due diligence across technical, operational, and transactional dimensions:

Technical Capabilities Verification

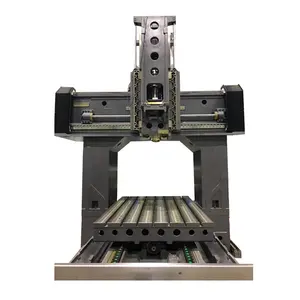

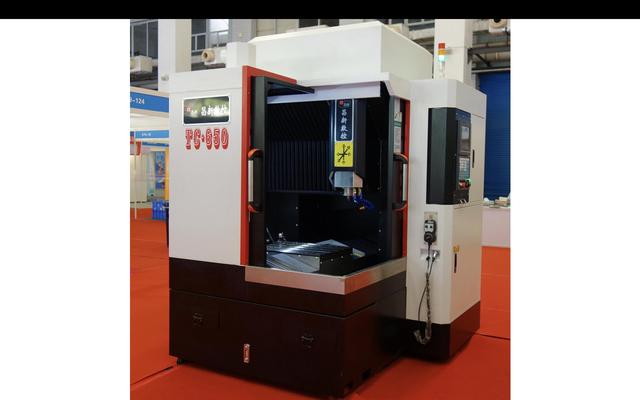

Confirm suppliers possess in-house CNC lathes, milling machines, and machining centers capable of handling materials including stainless steel, aluminum, brass, and engineering plastics. Prioritize vendors with documented experience in tight-tolerance machining (±0.005mm) and complex geometries. For electromechanical integration, verify availability of automatic lubrication controller systems and compatibility with Industry 4.0 monitoring protocols.

Quality Management Systems

While formal certifications (e.g., ISO 9001) are not universally listed, consistent on-time delivery rates at 100%—as observed across multiple suppliers—indicate robust internal quality controls. Reorder rates above 60%, seen in top-tier vendors, reflect customer satisfaction with dimensional accuracy, surface finish consistency, and batch-to-batch repeatability. Request inspection reports, first-article testing data, and process capability (Cp/Cpk) metrics where available.

Production Scalability & Responsiveness

Evaluate infrastructure indicators such as facility size, workforce specialization, and R&D investment. Key benchmarks include:

- Dedicated machining and sheet metal fabrication lines

- Response time ≤2 hours for inquiry resolution

- On-time delivery performance consistently at 100%

- Monthly online revenue exceeding US $90,000 as proxy for order volume

Cross-reference digital product listings with service scope to assess customization depth, including OEM/ODM support, 3D model-based programming, and rapid iteration cycles.

Transaction Risk Mitigation

Implement secure payment terms, especially with newer or lower-visibility suppliers. Utilize verifiable transaction histories, sample testing, and phased order rollouts to de-risk procurement. For critical applications, require material test certificates (MTCs), coordinate measuring machine (CMM) reports, and pre-shipment inspections.

What Are the Best Machining and CNC Technology Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization |

|---|---|---|---|---|---|---|---|

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, Milling Machines, Band Saw | US $120,000+ | 100% | 40% | ≤2h | Yes (automatic lubrication systems) |

| Zhengzhou Yunkai Precision Machinery Co., Ltd. | Henan, CN | Machining Services, Sheet Metal Fabrication, Moulds | US $300+ | 100% | <15% | ≤1h | OEM/ODM supported |

| Dongguan Wanhong Intelligent Manufacturing Technology Co., Ltd. | Guangdong, CN | Machining Services, Sheet Metal, Electronics Enclosures | US $180,000+ | 100% | 60% | ≤2h | Advanced CNC machining, stainless steel focus |

| Ningbo Target Machinery Co., Ltd. | Zhejiang, CN | Machining Services, Casting, Worm Gears, Shafts | US $90,000+ | 100% | 66% | ≤2h | Non-standard CNC processing |

| Bozhan Precision Hardware INC | Unknown, CN | Sheet Metal Fabrication, Machining, Casting, Forging | Data Unavailable | Not Verified | Not Verified | ≤2h | Custom milling, 5-axis CNC parts |

Performance Analysis

Dongguan Wanhong and Ningbo Target demonstrate strong customer retention, with reorder rates of 60% and 66% respectively, indicating high satisfaction with quality and service reliability. Zhengzhou Yunkai leads in responsiveness (≤1h), making it suitable for urgent prototyping needs despite lower reorder frequency. Shandong Lu Young offers broad equipment diversity, including manual lathes and band saws, ideal for buyers seeking hybrid production solutions. Ningbo Target stands out for technical innovation in non-standard CNC processing and gear manufacturing. Bozhan Precision, while lacking verifiable performance data, advertises 5-axis machining capabilities, suggesting potential for complex aerospace or medical components pending further due diligence.

FAQs

What materials can CNC machining suppliers process?

Common materials include stainless steel, aluminum alloys (e.g., 6061, 7075), brass, carbon steel, titanium, and engineering plastics like POM and PEEK. Suppliers typically specify material compatibility per product listing, with some specializing in corrosion-resistant or high-strength applications.

What is the typical MOQ and pricing range?

Minimum Order Quantities vary: 1 piece for prototypes, 10–100 pieces for standard runs. Unit prices range from $0.07 to $5.49 depending on complexity, material, and finishing requirements. High-volume orders (1,000+ units) often unlock unit cost reductions of 20–35%.

How long do CNC machining projects take?

Standard lead time is 15–25 days, including programming, machining, and quality checks. Rapid-turnaround services may deliver samples in 7–10 days. Complex 5-axis or multi-process parts may require 30+ days.

Can suppliers handle full project lifecycle support?

Top-tier suppliers offer design-for-manufacturability (DFM) feedback, 3D modeling, prototype validation, and post-processing (e.g., plating, heat treatment). Some integrate IoT-enabled monitoring for production transparency.

Are international shipping and customs documentation provided?

Most suppliers support global export with FOB or CIF terms. Confirm inclusion of commercial invoices, packing lists, and material certifications. For regulated industries, ensure compliance with destination-specific standards (e.g., RoHS, REACH).