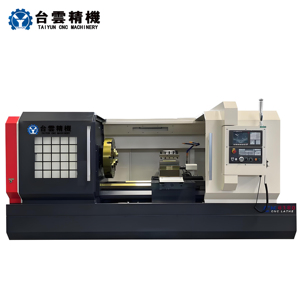

Cnc Lathe And Milling Machine

Top sponsor listing

Top sponsor listing

About cnc lathe and milling machine

Where to Find CNC Lathe and Milling Machine Suppliers?

China remains the global epicenter for CNC lathe and milling machine manufacturing, with key industrial clusters in Jiangsu, Anhui, Shandong, and Guangdong provinces. These regions host vertically integrated supply chains that support end-to-end production—from casting and heat treatment to precision machining and final assembly—enabling competitive pricing and scalable output. Suzhou and Chizhou in eastern China specialize in compact combo machines for small-part machining, while Shandong and Shenzhen serve high-precision and multi-axis CNC systems for aerospace, automotive, and mold-making industries.

The concentration of component suppliers, skilled labor, and specialized logistics networks within 50km radii allows manufacturers to maintain lean inventories and rapid turnaround times. Average lead times range from 30–60 days depending on customization complexity, with standard models often available for immediate dispatch. Localized steel and cast iron sourcing reduces material costs by 18–25% compared to Western counterparts, while automation integration in modern facilities ensures consistent dimensional accuracy down to ±0.005mm.

How to Choose CNC Lathe and Milling Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international quality standards such as ISO 9001 for quality management and CE marking for electrical and mechanical safety compliance. For export markets, ensure controllers (e.g., Fanuc, Siemens, or Syntec) are pre-configured to meet regional voltage and operational protocols. Request test reports on spindle runout, positioning accuracy, and surface finish consistency from recent production batches.

Production Capability Audits

Assess core infrastructure indicators:

- Minimum factory footprint of 3,000m² indicating capacity for dedicated CNC assembly lines

- In-house machining capabilities including grinding, gear cutting, and hard turning to reduce outsourcing dependencies

- R&D teams focused on control system optimization and vibration damping technologies

Cross-reference online revenue data and reorder rates as proxies for market acceptance and after-sales reliability.

Transaction Safeguards

Prioritize suppliers offering structured order protection mechanisms. Confirm availability of third-party inspection services prior to shipment and insist on detailed packing lists with serial-numbered components. Evaluate responsiveness through documented communication logs—sub-3-hour response times correlate strongly with proactive issue resolution during transit and installation phases.

What Are the Best CNC Lathe and Milling Machine Suppliers?

| Company Name | Location | Main Product Focus | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Key Offerings |

|---|---|---|---|---|---|---|---|---|

| Suzhou Konlida Precision Electronic Co., Ltd. | Jiangsu, CN | Machining Services (389 listings) | US $430,000+ | 100% | ≤3h | 20% | Color, material, size, precision drawing, logo, packaging, graphic | High-volume machining services with broad secondary processing capabilities |

| Chizhou Syntop CNC Industrial Co., Ltd. | Anhui, CN | Manual Lathe (628 listings) | US $80,000+ | 100% | ≤3h | 27% | Not specified | Combo lathe-mill machines; cost-effective entry-level CNC and manual models |

| Shandong Plurtel Machine Tool Co., ltd | Shandong, CN | CNC Lathes & Slant-Bed Models | US $10,000+ | 100% | ≤3h | 50% | Color, material, size, logo, packaging, label, graphic | Precision slant-bed CNC lathes; automated turning-milling units |

| Shenzhen Richon Industry Co., Ltd. | Guangdong, CN | Multi-Axis CNC Systems | US $290,000+ | 88% | ≤2h | 16% | System, color, material, size, logo, packaging, label, graphic | 3–5 axis vertical machining centers; heavy-duty metal cutting solutions |

| Wenzhou Spring Trading Co., Ltd. | Zhejiang, CN | Vertical Machining Centers | US $5,000+ | 100% | ≤2h | 66% | Not specified | Triple-spindle vertical machining centers; high-speed drilling-tapping systems |

Performance Analysis

Wenzhou Spring Trading stands out with a 66% reorder rate—the highest among listed suppliers—indicating strong post-sale satisfaction despite lower online revenue. Shandong Plurtel demonstrates robust customer retention (50% reorder rate) and offers extensive customization, suggesting effective alignment with niche industrial requirements. Suzhou Konlida leads in digital sales volume (over US$430K), reflecting diversified service offerings beyond equipment sales into contract machining. While Shenzhen Richon provides advanced multi-axis technology, its 88% on-time delivery rate presents a potential risk for time-sensitive deployments. Buyers seeking high-reliability partners should prioritize suppliers with verified 100% on-time performance and comprehensive customization frameworks.

FAQs

How to verify CNC lathe and milling machine supplier reliability?

Validate certifications through official registries and request factory audit reports covering quality control processes, tool calibration schedules, and raw material traceability. Analyze transaction history for consistent fulfillment patterns and review customer feedback focusing on machine rigidity, controller stability, and after-sales technical support.

What is the typical MOQ and lead time?

Standard configurations typically have an MOQ of 1 set, with lead times ranging from 30 days for stock models to 60 days for customized builds. High-complexity machines (e.g., triple-spindle vertical centers) may require up to 90 days due to extended testing cycles.

Do suppliers offer customization options?

Yes, leading suppliers provide configurable parameters including spindle speed, travel dimensions, control systems, coolant delivery, and branding elements. Full engineering drawings and CAD models are commonly exchanged to finalize modifications before production begins.

Can these machines be shipped internationally?

All major suppliers support global shipping via FOB or CIF terms. Ensure proper crating, marine insurance, and customs documentation for smooth clearance. Sea freight is standard for full-container loads, while air transport is viable for urgent single-unit deliveries.

Is sample testing available before bulk ordering?

Suppliers generally allow prototype validation upon payment of a sample fee, which may be credited toward future orders. Testing should include dry runs, cutting trials with customer-specified materials, and measurement of repeatability under continuous operation.