Cnc Lathe Machining

Top sponsor listing

Top sponsor listing

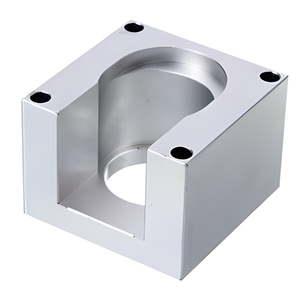

About cnc lathe machining

Where to Find CNC Lathe Machining Suppliers?

China remains the global hub for CNC lathe machining services, with key supplier clusters in Zhejiang, Jiangsu, and Shandong provinces. These regions host vertically integrated manufacturing ecosystems that combine precision engineering facilities with robust metalworking supply chains. Ningbo and Wuxi serve as core centers for machining service providers, offering access to multi-axis CNC turning, milling, and wire-cutting technologies. Shandong's industrial base excels in CNC machine tool production, supporting both component manufacturing and full-system integration.

The concentration of suppliers enables economies of scale, localized sourcing of raw materials (including stainless steel, aluminum, and alloy metals), and rapid prototyping capabilities. Buyers benefit from lead times averaging 15–30 days for custom parts and immediate availability of standard machining services. With over 80% of listed suppliers reporting 100% on-time delivery rates, the region demonstrates strong operational reliability. Cost advantages range from 20–40% compared to Western counterparts due to lower labor costs and streamlined logistics networks.

How to Choose CNC Lathe Machining Suppliers?

Selecting a reliable partner requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm availability of 3-, 4-, and 5-axis CNC lathes capable of achieving tolerances down to ±0.005 mm. Prioritize suppliers listing machining services as their primary product category, indicating specialization. Review equipment specifications such as spindle speed, tool magazine capacity, and coolant systems for alignment with your production requirements.

Quality Assurance Protocols

While formal certifications (e.g., ISO 9001) are not explicitly stated in available data, consistent performance metrics suggest adherence to quality management practices. Look for suppliers highlighting on-time delivery at 100%, which correlates with disciplined process control. Reorder rates—where available—offer insight into customer satisfaction; those exceeding 20% indicate higher service reliability.

Production Capacity & Responsiveness

Evaluate based on the following benchmarks:

- Response time ≤2 hours for initial inquiry handling

- Minimum online revenue exceeding US $10,000/year as an indicator of commercial activity

- Portfolio depth: Suppliers with 100+ listings in machining services demonstrate scalable operations

- In-house capabilities including color film treatment, packaging labeling, and graphic/logo application for value-added finishing

Transaction Risk Mitigation

Utilize secure payment mechanisms and request sample validation before bulk orders. Assess customization flexibility by submitting detailed drawings or CAD files and measuring turnaround time for quotes and prototypes. Confirm packaging standards and export experience, particularly for fragile or high-precision components requiring shock-resistant shipment solutions.

What Are the Best CNC Lathe Machining Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Price Range (Unit) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Ningbo Baozhen Machinery Co., Ltd. | Machining Services (1,099) | 100% | ≤2h | 20% | US $70,000+ | Color, size, material, drawing, logo, packaging | Not specified | Not specified |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Machining Services (872) | 100% | ≤2h | - | US $10,000+ | Limited details | $0.10–$4.90 | 1 piece |

| Wuxi Jintong Furnace Co., Ltd. | CNC Lathe (109) | 100% | ≤6h | - | US $140,000+ | Machine-specific customization | $3,200–$18,900/set | 1 set |

| Yongnian District Xuepai Cnc Lathe Store | Machining Services (146) | 100% | ≤1h | <15% | US $100+ | Precision mechanical parts, stainless steel/aluminum | $0.31–$5.00 | 1 piece |

| Taiyun (Shandong) Cnc Machine Tool Co., Ltd. | CNC Vertical/Horizontal Lathes | 100% | ≤2h | - | US $1,000+ | High-performance machine tools | $4,288–$37,000 | 1 piece/set |

Performance Analysis

Ningbo Baozhen Machinery stands out with the highest volume of machining service listings (1,099) and a verified 20% reorder rate, suggesting strong client retention and process consistency. JINKE VIET NAM INDUSTRIAL offers competitive per-unit pricing starting at $0.10, ideal for high-volume precision components. Wuxi Jintong leads in capital equipment sales, with CNC lathes priced between $3,200 and $18,900 per set, catering to buyers seeking turnkey machine procurement. Yongnian Xuepai achieves the fastest response time (≤1h), advantageous for urgent RFQs, though its sub-15% reorder rate may indicate room for service improvement. Taiyun (Shandong) specializes in medium-to-large CNC vertical lathes, targeting industrial clients needing heavy-duty machining capacity.

FAQs

What materials are commonly processed in CNC lathe machining?

Suppliers typically handle stainless steel, aluminum, carbon steel, brass, and alloy metals. Some offer specialized processing for titanium or plastics upon request. Material selection should align with corrosion resistance, strength, and machinability requirements.

What is the typical minimum order quantity (MOQ)?

Most suppliers list MOQs as low as 1 piece, enabling prototyping and small-batch production. Bulk pricing usually applies at 100+ units, with discounts varying by complexity and material usage.

How long does it take to receive custom-machined parts?

Standard lead time ranges from 10–25 days post-design approval. Complex geometries or tight tolerance requirements may extend production by 5–10 days. Add 5–15 days for international shipping depending on destination and method.

Can suppliers provide design and drawing support?

Yes, many offer technical collaboration including CAD/CAM file conversion, DFM analysis, and tolerance optimization. Suppliers like Ningbo Baozhen explicitly list "drawings" as a customizable parameter, indicating engineering-level engagement.

Are surface treatments and finishing options available?

Common options include anodizing, plating, powder coating, and color film application. Packaging labels, laser engraving, and logo/graphic integration are also offered by select suppliers for brand-specific part identification.