Cnc Machining Process

1/12

1/12

1/25

1/25

1/21

1/21

CN

CN

1/18

1/18

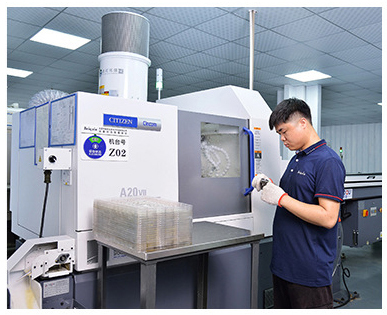

About cnc machining process

Where to Find CNC Machining Process Suppliers?

China remains the global epicenter for precision CNC machining services, with concentrated manufacturing hubs in Guangdong and Jiangsu provinces driving competitive advantages. Shenzhen and Dongguan in Guangdong account for over 45% of China’s export-oriented CNC machining operations, supported by mature supply chains for aluminum, stainless steel, and engineering plastics. These regions offer integrated ecosystems combining tooling, metrology, and secondary processing under one roof, enabling rapid prototyping and scalable production.

The industrial clusters provide measurable efficiencies: localized access to raw materials reduces component lead times by 20–30%, while vertical integration across milling, turning, grinding, and surface treatment processes supports complex part fabrication within single facilities. Buyers benefit from agile production models—typical turnaround for custom prototypes ranges from 7–14 days, with volume orders fulfilling in 25–35 days. Cost structures reflect economies of scale, with per-unit pricing as low as $0.10 for high-volume machined components, undercutting Western suppliers by 35–50% on comparable tolerances (±0.005 mm).

How to Choose CNC Machining Process Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

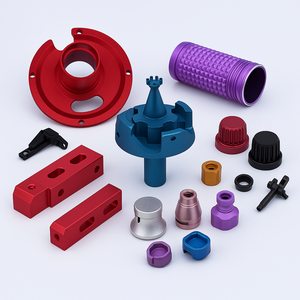

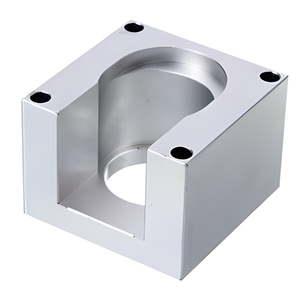

Confirm availability of multi-axis CNC centers (3-axis, 4-axis, and 5-axis) for complex geometries. Assess material compatibility—leading suppliers support aluminum (6061, 7075), stainless steel (303, 304, 316), brass, titanium, and engineering plastics (PEEK, Delrin). Tolerance adherence to ISO 2768-mK or tighter is standard; request first-article inspection reports (FAIRs) and CMM validation for critical features.

Production Infrastructure Audit

Evaluate core operational metrics:

- Minimum facility size of 2,000m² indicating dedicated production zones

- In-house capabilities spanning CNC turning, milling, wire EDM, and surface finishing (anodizing, plating, passivation)

- Integration of CAD/CAM software (SolidWorks, Mastercam) and reverse engineering tools

Cross-reference online order history and reorder rates to validate consistency in quality and delivery performance.

Quality & Transaction Assurance

Prioritize suppliers demonstrating formal quality management systems, ideally ISO 9001-certified. While not always listed, consistent on-time delivery (≥98%) and sub-2-hour response times correlate with robust internal workflows. Utilize documented sampling protocols—request physical or digital samples prior to full commitment. Escrow-based payment terms mitigate financial risk during initial engagements.

What Are the Best CNC Machining Process Suppliers?

| Company Name | Location | Online Revenue | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Hongxiangsheng Technology Co., Ltd. | Shenzhen, CN | US $1,000+ | Machining Services, Nuts, Sheet Metal Fabrication, Bolts | 100% | ≤1h | 25% | 1 piece/pack | $0.12–0.58 |

| Dongguan Xingyao Precision Hardware Co., Ltd. | Dongguan, CN | US $7,000+ | Machining Services | 100% | ≤3h | 100% | 2 pieces | $0.35–1.65 |

| Shenzhen VMT Metal Product Co., Ltd. | Shenzhen, CN | US $190,000+ | Machining Services, Sheet Metal Fabrication, Casting Services | 100% | ≤2h | 37% | 1 piece | $0.16–3.00 |

| Shenzhen Rui Xinqing Hardware Plastic Products Co., Ltd. | Shenzhen, CN | US $400+ | Machining Services, Moulds, Sheet Metal Fabrication | 100% | ≤1h | - | 1 piece/set | $0.10–10.00 |

| Zhuhai Mingjiang Machinery Technology Co., Ltd. | Zhuhai, CN | - | Machining Services | 100% | ≤11h | - | 5 pieces | $0.30–5.00 |

Performance Analysis

Shenzhen VMT leads in transaction volume (US $190,000+ online revenue), suggesting strong market acceptance and export activity, complemented by diversified capabilities including casting and sheet metal work. Dongguan Xingyao stands out with a 100% reorder rate, indicating high customer satisfaction despite higher base pricing. Multiple suppliers report 100% on-time delivery, reflecting disciplined production planning. MOQ flexibility varies significantly—suppliers like Rui Xinqing accept single-piece orders, ideal for prototyping, while Zhuhai Mingjiang requires minimum batches of five, better suited for early-stage production runs. Price dispersion highlights strategic positioning: Rui Xinqing offers entry-level pricing from $0.10/unit, whereas specialized providers command premiums up to $10/set for complex assemblies.

FAQs

How to verify CNC machining supplier reliability?

Assess responsiveness (sub-2h replies indicate active operations), review listed product range for technical alignment, and analyze order history where available. Request process capability documentation, including equipment lists, inspection protocols, and material traceability procedures.

What is the typical sampling timeline for CNC parts?

Prototype lead time averages 7–10 days for simple geometries in common materials. Complex or tight-tolerance components may require 14 days. Add 3–7 days for international express shipping. Digital samples (CAD models, inspection reports) can be provided within 48 hours.

Can CNC machining suppliers handle global shipments?

Yes, most established suppliers have export experience and partner with freight forwarders for worldwide delivery. Confirm Incoterms (FOB, CIF) upfront and verify packaging standards for sensitive machined components. Air freight is standard for samples; sea freight applies to bulk orders.

Do suppliers support customization and low-volume production?

Extensively. All listed suppliers offer OEM/ODM services with no design fees for standard modifications. Low MOQs (1–5 units) accommodate prototyping and niche applications. Full customization—from material selection to surface finish—is standard practice.

How to negotiate favorable terms with CNC machining providers?

Leverage volume commitments for price scaling. Early engagement during prototype phase builds supplier investment. Consolidate multiple part numbers into a single vendor relationship to improve priority scheduling and reduce setup costs.