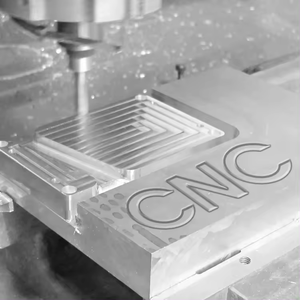

Cnc Machining Production

Top sponsor listing

Top sponsor listing

About cnc machining production

Where to Find CNC Machining Production Suppliers?

China remains the global epicenter for precision CNC machining production, with leading suppliers concentrated in Guangdong and Jiangsu provinces. Dongguan and Shenzhen serve as key hubs for high-precision metal parts manufacturing, hosting vertically integrated facilities that support rapid prototyping and mass production. These regions benefit from mature industrial ecosystems—proximity to material suppliers, surface treatment providers, and logistics networks enables efficient coordination across the supply chain.

Suppliers in this cluster specialize in multi-axis CNC turning, milling, and 5-axis machining, serving industries ranging from automotive and aerospace to medical devices and consumer electronics. The integration of automation and digital quality control systems allows consistent tolerances down to ±0.005mm. Buyers gain access to scalable production capacity, with lead times typically ranging from 15–25 days for custom orders. Localized sourcing reduces costs by 20–35% compared to Western manufacturers, while maintaining compliance with international standards.

How to Choose CNC Machining Production Suppliers?

Effective supplier selection requires a structured evaluation of technical capability, operational reliability, and transactional transparency:

Technical & Quality Compliance

Verify adherence to ISO 9001 or IATF 16949 standards as baseline quality assurance. For regulated sectors (e.g., medical, aerospace), confirm additional certifications such as RoHS or AS9100. Request documentation for inspection protocols, including CMM reports, first-article inspections, and process capability (Cp/Cpk) data. Surface treatments like anodizing, plating, or passivation should align with industry specifications.

Production Capacity Assessment

Evaluate core capabilities through the following indicators:

- Minimum facility size of 2,000m² to ensure scalability

- In-house CNC machining centers (3-axis, 4-axis, 5-axis), lathes, and milling machines

- Material processing range: aluminum (6061, 7075), stainless steel (304, 316), brass, copper, titanium, and engineering plastics

- Dedicated quality control stations with metrology equipment (e.g., coordinate measuring machines, optical comparators)

Cross-reference on-time delivery rates (target ≥97%) and reorder rates (indicative of customer satisfaction) with response time metrics to assess operational efficiency.

Transaction & Risk Mitigation

Prioritize suppliers offering transparent order tracking and third-party inspection options. Use secure payment mechanisms where possible, especially for initial engagements. Require sample validation before full-scale production—benchmark dimensional accuracy, surface finish, and material composition against provided drawings. Confirm packaging and labeling compliance for international shipments.

What Are the Best CNC Machining Production Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Dongguan Bochuang Precision Manufacturing Co., Ltd. | Guangdong, CN | Machining Services (357), Sheet Metal Fabrication (79) | US $20,000+ | 100% | ≤2h | 25% | Color, material, size, logo, packaging, graphic | 1 piece |

| Shenzhen Roson Hardware Co., Ltd. | Guangdong, CN | Machining Services (157), Mills (6) | US $100,000+ | 100% | ≤3h | 38% | Limited (product-specific) | 1–5 pieces |

| Dongguan Bie Hardware Co., Ltd. | Guangdong, CN | 5-Axis CNC, Prototyping, Auto Parts | US $270,000+ | 97% | ≤2h | 50% | Steel, brass, chrome, laser marking, anodic treatment, 3D drawings | 1 piece |

| YAOPENG METAL PRODUCTS CO., LIMITED | Guangdong, CN | Custom CNC, Stainless Steel, Heat Sinks | US $40,000+ | 100% | ≤2h | 16% | Silk print, oxidation, die casting, polishing, label, drawing | 1 piece |

| Huzhou Dear Industry Co., Ltd. | Zhejiang, CN | CNC Lathe, Small-Order Machining | US $370,000+ | 100% | ≤6h | 48% | Color, packaging, TPU/EPDM materials, injection-related | 1–2 pieces |

Performance Analysis

Dongguan Bie Hardware stands out with a 50% reorder rate and extensive customization capabilities, indicating strong client retention and technical flexibility. Huzhou Dear Industry demonstrates high transaction volume (US $370,000+ online revenue) and caters well to low-MOQ needs, ideal for prototyping or niche applications. Shenzhen Roson offers competitive pricing and fast turnaround, supported by a 38% reorder rate and robust machining output. Dongguan Bochuang leads in product diversity with over 350 listings in machining services, suitable for buyers seeking broad technical coverage. YAOPENG, while reliable in delivery, has a lower reorder rate, suggesting room for improvement in long-term client engagement. All top-tier suppliers offer MOQs of 1 piece, enabling cost-effective sampling and small-batch production.

FAQs

How to verify CNC machining supplier reliability?

Request copies of quality management system certifications (e.g., ISO 9001) and validate them through issuing bodies. Conduct virtual factory audits to observe CNC equipment, QC processes, and inventory management. Analyze historical performance metrics such as on-time delivery rate, response time, and customer reviews focused on consistency and communication.

What is the typical lead time for CNC machined parts?

Standard lead times range from 10–15 days for prototypes and 15–25 days for bulk production, depending on complexity and order volume. Rush services may reduce timelines by 3–5 days at a premium. Add 5–10 days for surface treatments like anodizing or plating.

Do CNC suppliers support custom materials and finishes?

Yes, most suppliers process aluminum, stainless steel, brass, copper, and select engineering plastics. Custom finishes include sandblasting, polishing, anodizing (Type II/III), nickel plating, and powder coating. Confirm material traceability and process compatibility before ordering.

Can I request samples before mass production?

Yes, all listed suppliers offer sample production. Sample costs vary based on complexity but typically cover 40–60% of unit price. Some waive fees upon confirmation of large-volume orders. Expect 7–14 days for sample manufacturing and 3–7 days for express shipping.

What file formats are accepted for CNC design submissions?

Standard formats include STEP (.stp), IGES (.igs), SolidWorks (.sldprt), and DWG/DXF for 2D drawings. Suppliers require detailed GD&T callouts, tolerances, and surface finish specifications. Most provide DFM feedback within 24–48 hours of submission.