Cnc Machining Operations

Top sponsor listing

Top sponsor listing

1/29

1/29

1/12

1/12

1/16

1/16

1/28

1/28

1/24

1/24

1/32

1/32

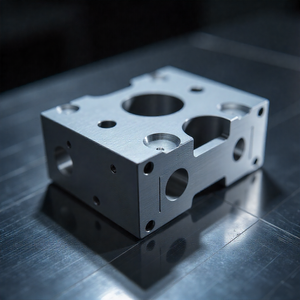

About cnc machining operations

Where to Find CNC Machining Operations Suppliers?

China remains a global hub for precision CNC machining operations, with concentrated manufacturing clusters in Shanghai, Dongguan, Qingdao, and Shenzhen offering robust industrial ecosystems. These regions host vertically integrated facilities equipped with multi-axis milling, turning, grinding, and EDM capabilities, enabling end-to-end production from prototyping to high-volume runs. Proximity to raw material suppliers and port infrastructure reduces logistics costs and supports rapid turnaround—critical for time-sensitive engineering projects.

The sector benefits from mature supply chains encompassing sheet metal fabrication, casting, molding, and surface treatment services, allowing suppliers to offer one-stop manufacturing solutions. Facilities typically range from 2,000–25,000+ m², supporting scalable output across industries such as automotive, medical devices, aerospace, and consumer electronics. Buyers can expect lead times of 10–25 days for standard orders, with 20–30% cost advantages over domestic Western manufacturers due to lower labor and operational overheads.

How to Choose CNC Machining Operations Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

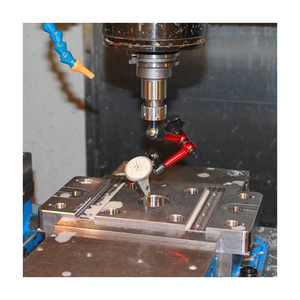

Technical Capabilities

Verify access to advanced machinery including 5-axis CNC mills, Swiss lathes, and laser cutting systems. Suppliers should demonstrate proficiency in processing diverse materials—aluminum, stainless steel, brass, titanium, and engineering plastics—with tolerances down to ±0.005 mm. Demand detailed process documentation, including GD&T compliance, CMM inspection reports, and first-article testing protocols.

Quality Assurance Systems

Prioritize suppliers with ISO 9001 certification or equivalent quality management frameworks. Look for evidence of in-process quality controls such as hardness testing, anodizing, passivation, sandblasting, and electroplating validation. Reorder rates above 25% and on-time delivery performance exceeding 94% indicate consistent reliability and customer satisfaction.

Customization & Prototyping Support

Assess capability for low-volume prototyping (MOQs as low as 1 piece) and full-scale production. Leading suppliers support customization via:

- Drawing formats: STEP, IGES, DWG, PDF with geometric dimensioning

- Surface finishes: anodizing (Type II/III), powder coating, brushing, polishing

- Secondary operations: welding, riveting, stamping, laser engraving, packaging labeling

- Rapid prototyping using CNC, vacuum casting, or 3D drawing integration

Cross-reference stated capabilities with product listings and response times (ideally ≤2 hours) to assess operational responsiveness.

Transaction Risk Mitigation

Utilize secure payment mechanisms that align with order milestones. Confirm packaging standards, export documentation support, and FOB/CIF shipping options. Request sample units to validate dimensional accuracy, material integrity, and finish quality before scaling procurement.

What Are the Best CNC Machining Operations Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Production Highlights |

|---|---|---|---|---|---|---|---|

| Shanghai Yecheng Mechanical And Electrical Co., Ltd. | Machining Services | 100% | ≤1h | 26% | US $440,000+ | Yes | Precision micro parts, deep machining, anodizing, CMM detection, laser cutting, bending |

| Dongguan Ouli Electronics & Technology Co., Ltd. | Machining Services, Nuts, Screws, Washers | 86% | ≤2h | 50% | US $150,000+ | Limited | High-volume fasteners, auto parts, laser cutting, OEM machining |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Machining Services, Sheet Metal, Moulds, Casting | 100% | ≤2h | - | US $10,000+ | Yes | 5-axis CNC milling, rapid prototyping, heat press, casting services |

| 24K Investment (Qingdao) Co., Ltd. | Machining Services, Sheet Metal, Moulds | 94% | ≤2h | 20% | US $10,000+ | Yes | 5-axis CNC milling, one-stop custom machining, precision brass/stainless steel components |

| Shenzhen Tuowei Model Technology Co., Limited | Machining Services, Silicone Molding, Injection Molds | 96% | ≤3h | 29% | US $330,000+ | Yes | Five-axis machining, vacuum casting, mold design, graphic logo engraving, varnish finishes |

Performance Analysis

Shanghai-based Yecheng leads in delivery consistency (100%) and responsiveness (≤1h), backed by extensive online revenue and broad customization capacity. Dongguan Ouli stands out with a 50% reorder rate, indicating strong client retention in fastener and automotive component manufacturing despite moderate on-time performance. Shenzhen Tuowei combines high technical flexibility with proven scalability, serving medical and drone sectors through advanced finishing and mold integration. JINKE Vietnam and 24K Investment offer cost-effective entry points for small-batch prototyping with access to multi-axis machining and secondary processes.

FAQs

How to verify CNC machining supplier reliability?

Evaluate on-time delivery records, reorder rates, and response speed as proxies for operational discipline. Request evidence of ISO certification, facility audits, and sample inspection reports. Validate material traceability and testing procedures for critical applications.

What is the typical MOQ and pricing range?

MOQs vary from 1 piece for prototypes to 100+ units for volume pricing. Unit costs range from $0.10–$65 depending on complexity, material, and finishing requirements. High-precision or multi-process components command premium rates.

Do suppliers support international shipping and customs clearance?

Yes, most experienced suppliers manage global logistics, providing export documentation and compliance support. Confirm Incoterm preferences (FOB, CIF) and coordinate with freight partners for duty assessment and import regulations.

Can I request free samples?

Sample fees are common but often refundable against future orders. Suppliers may require payment covering 30–50% of production cost for custom prototypes, especially for complex geometries or exotic materials.

How long does it take to receive custom machined parts?

Standard lead time ranges from 10–20 days post-design approval. Rapid prototyping services deliver within 5–7 days. Add 7–14 days for international air freight or 25–40 days for sea shipment depending on destination.