Cnc Machining Work

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About cnc machining work

Where to Find CNC Machining Work Suppliers?

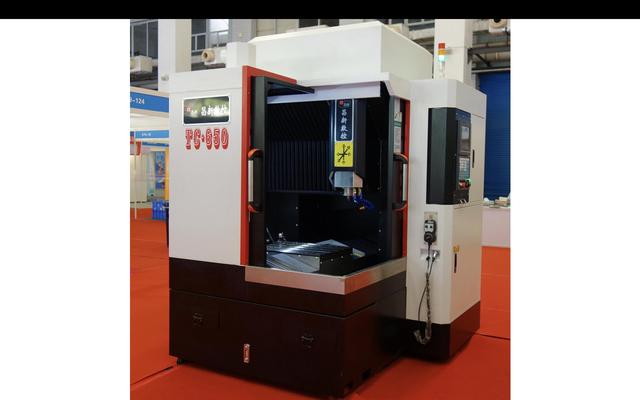

China remains the global hub for precision CNC machining services, with key manufacturing clusters concentrated in coastal industrial zones such as Zhejiang, Sichuan, Jiangsu, and Guangdong. These regions host a dense network of custom manufacturers equipped with advanced multi-axis CNC lathes, milling centers, and rapid prototyping infrastructure. Ningbo and Wuxi in Jiangsu province specialize in high-precision metal components for automotive and aerospace applications, while Chengdu-based suppliers serve medical, electronics, and automation sectors with tight-tolerance machining.

The regional ecosystems support vertically integrated production, enabling seamless transitions from design to finished parts within localized supply chains. This integration reduces lead times by 20–35% compared to offshore alternatives and supports cost efficiencies through access to raw materials like aluminum, stainless steel, titanium, brass, and engineering plastics. Buyers benefit from scalable production capabilities, with facilities offering batch processing for low-volume prototypes (1–10 pieces) up to mass production runs exceeding thousands of units monthly.

How to Choose CNC Machining Work Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm availability of 3-, 4-, and 5-axis CNC machining centers capable of achieving tolerances down to ±0.005 mm. Prioritize suppliers with in-house design and engineering support for DFM (Design for Manufacturability) feedback. Material expertise should include metals (aluminum 6061/7075, carbon steel, stainless steel 303/316, titanium, brass) and polymers (POM/Delrin, UHMW, HDPE, PEEK). Surface treatment options such as anodizing, sandblasting, painting, plating, and laser engraving indicate process maturity.

Quality & Compliance Standards

While formal ISO 9001 certification is not explicitly stated in all supplier profiles, on-time delivery rates above 95% and consistent reorder rates suggest robust internal quality management systems. For regulated industries (medical, aerospace, defense), request evidence of documented inspection protocols, first-article testing, and traceable material certifications. Dimensional inspection reports and GD&T (Geometric Dimensioning and Tolerancing) compliance are essential for critical components.

Production Scalability and Responsiveness

Evaluate responsiveness metrics: target response times under 4 hours and on-time delivery performance exceeding 90%. Reorder rates provide insight into customer satisfaction—suppliers like Newtop Intelligence Technology report 100% reorder rates, indicating strong service alignment. Facility size and online revenue indicators (e.g., US $60,000+ annual digital sales) correlate with capacity for handling medium to large orders.

Transaction Risk Mitigation

Leverage structured communication to validate claims. Request facility videos, machine lists, or virtual audits before order placement. Use milestone-based payments where possible, especially for complex or high-value projects. Insist on sample approval prior to full production to verify dimensional accuracy, surface finish, and material conformity.

What Are the Best CNC Machining Work Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Notable Materials |

|---|---|---|---|---|---|---|---|---|

| Ningbo Yizhong Hardware Products Co., Ltd. | Zhejiang, CN | Custom Manufacturer | 75% | ≤3h | 50% | US $10,000+ | Titanium drawing, main product focus on machining | Aluminum, Titanium, Steel |

| Chengdu Jingbang Technology Co., Ltd. | Sichuan, CN | Multispecialty Supplier | 100% | ≤5h | <15% | US $500,000+ | Thread sizes, color, packaging, sandblasting, labeling, logo, graphic | Stainless Steel, Brass, Carbon Steel |

| SkyReach Intelligent MFG Limited | Guangdong, CN | Custom Manufacturer | 84% | ≤4h | 16% | US $20,000+ | Color, material, size, logo, packaging, label, graphic | POM, UHMW, PE, Delrin, HDPE, Stainless Steel |

| Newtop Intelligence Technology (Wuxi) Co., Ltd. | Jiangsu, CN | Custom Manufacturer | 100% | ≤4h | 100% | US $60,000+ | Color, material, size, logo, packaging, label, graphic | Aluminum, Titanium, Carbon, Stainless Steel |

| TONGSHENG TONGCHUANG INTELLIGENT EQUIPMENT COMPANY LIMITED | Guangdong, CN | Multispecialty Supplier | 100% | ≤11h | - | US $90+ | Main products include machining services, molds, sheet metal, springs, bolts, pins | Stainless Steel, Metal Alloys |

Performance Analysis

Chengdu Jingbang Technology and Newtop Intelligence Technology stand out for perfect on-time delivery records (100%), with the latter also reporting a 100% reorder rate—indicating exceptional client retention and execution reliability. Despite lower reported online revenue, Newtop demonstrates strong customization depth and fast turnaround, ideal for precision micro-machined components priced from $0.20/unit. Chengdu Jingbang’s higher transaction volume (US $500,000+) reflects scalability for larger contracts, though its sub-15% reorder rate suggests room for improvement in long-term client engagement.

Ningbo Yizhong specializes in titanium machining, catering to niche industrial and defense applications, but its 75% on-time delivery rate warrants closer due diligence. SkyReach offers broad polymer and metal processing capabilities at competitive pricing ($0.50–$3.89/unit), suitable for prototyping and small-batch production. TONGSHENG TONGCHUANG provides diversified manufacturing services beyond CNC work, including mold-making and sheet metal fabrication, though limited financial transparency may pose risk for high-stakes procurement.

FAQs

What is the typical MOQ for CNC machining work?

Most suppliers offer flexible MOQs starting from 1 piece, particularly for prototype or sample orders. Unit prices decrease significantly at volumes above 10–100 pieces. High-volume production runs are negotiable based on complexity and material usage.

How long does CNC machining take from order to delivery?

Standard lead times range from 10 to 25 days, depending on part complexity, finishing requirements, and order volume. Prototypes can be completed in 5–10 days. Add 5–14 days for international shipping via air freight.

Can I customize materials, finishes, and branding?

Yes. All listed suppliers offer extensive customization: material selection, dimensional adjustments, surface treatments (anodizing, sandblasting, painting), and branding options (laser engraving, labels, logos). Technical drawings in STEP, IGES, or DWG formats are typically required for accurate quoting.

Do suppliers provide samples before bulk production?

Sample production is standard practice. Most suppliers charge nominal fees that may be credited toward future orders. Expect 5–15 days for sample manufacturing and testing, depending on complexity.

What file formats are accepted for CNC machining quotes?

Commonly accepted formats include STEP (.stp), IGES (.igs), SolidWorks (.sldprt), DWG, DXF, and PDF drawings with clear dimensions and tolerances. 3D models with annotations improve quoting accuracy and reduce miscommunication.