Machining Operations And Machine Tools

Top sponsor listing

Top sponsor listing

1/8

1/8

CN

CN

1/3

1/3

About machining operations and machine tools

Where to Find Machining Operations and Machine Tools Suppliers?

China remains a dominant force in the global supply of machining operations and machine tools, with key manufacturing clusters concentrated in Guangdong, Chongqing, and Fujian provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering capabilities with cost-efficient production models. Guangdong—home to Foshan and Zhongshan—features advanced CNC machining hubs supported by robust electronics and automotive supply chains, enabling rapid prototyping and high-volume output. Chongqing’s machinery corridor specializes in heavy-duty metal fabrication and casting services, leveraging regional steel availability to reduce material costs by 15–25% compared to non-domestic suppliers.

The clustering effect allows suppliers to offer comprehensive service integration—from initial design and 3D modeling to final packaging and logistics coordination—within compact geographic zones. This proximity reduces lead times for both standard equipment and custom components, typically ranging from 15 to 45 days depending on complexity. Buyers benefit from scalable production options, access to multi-axis CNC systems (3–5 axis), and secondary processing such as anodizing, plating, and tempering. The region's mature infrastructure supports low minimum order quantities (MOQs) starting at 1 piece for precision parts, making it viable for prototyping and niche industrial applications.

How to Choose Machining Operations and Machine Tools Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

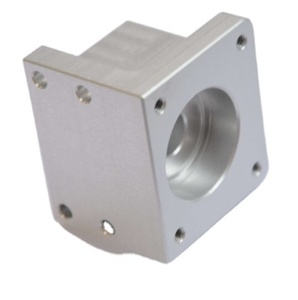

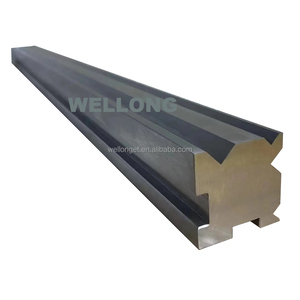

Confirm supplier proficiency in core processes including CNC milling, turning, sheet metal fabrication, and mold making. Prioritize vendors with documented experience in materials such as stainless steel, titanium, aluminum, and alloyed chromium steels. Request proof of engineering support, including CAD/CAM/3D drawing generation and tolerance control down to ±0.005mm for high-precision applications.

Production Infrastructure Assessment

Evaluate operational scale through objective indicators:

- Facility size exceeding 2,000m² indicating capacity for batch production

- In-house tooling, welding, and surface treatment capabilities

- Digital workflow integration (e.g., ERP or MES systems)

Cross-reference response time metrics (target ≤5 hours) and on-time delivery rates (>95%) as proxies for organizational efficiency and logistical reliability.

Quality & Transaction Assurance

While formal certifications (e.g., ISO 9001) are not explicitly stated in available data, prioritize suppliers demonstrating consistent performance records. Analyze reorder rates as an indicator of customer satisfaction—values above 25% suggest dependable quality and service. Utilize secure payment frameworks where possible, and insist on sample validation before full-scale orders. For customized tooling or machine components, require dimensioned drawings and material test reports prior to production launch.

What Are the Best Machining Operations and Machine Tools Suppliers?

| Company Name | Location | Main Services | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Holy Precision Manufacturing Co., Limited (Zhongshan) | Guangdong, CN | Machining Services, Sheet Metal Fabrication, Casting, Moulds | 87% | ≤5h | 36% | US $300,000+ | Yes (material, color, logo, packaging, engineering drawings) |

| Foshan SDS Smart Tech Co., Ltd. | Foshan, CN | CNC Vertical Machining Centers, Milling Machines (3–4 Axis) | 100% | ≤2h | 25% | US $410,000+ | Yes (size, color, labeling, graphics) |

| Chongqing Ce’an Machinery Co., Ltd. | Chongqing, CN | CNC Turning/Milling, Punching Tools, Lathe Parts | 100% | ≤2h | <15% | US $2,000+ | Limited public detail |

| JUNYING METAL MANUFACTURING CO., LIMITED | Unknown, CN | CNC Machining, Pinion Gears, Auto/Motorcycle Components | 100% | ≤6h | - | - | Not specified |

| Xinlined(Quanzhou) Machinery Import And Export Co., Ltd. | Fujian, CN | Custom Machine Tool Components, Gear Accessories, Bending/Welding | 100% | ≤10h | - | - | Yes (OEM, gear equipment, castings) |

Performance Analysis

Foshan SDS Smart Tech and Chongqing Ce’an stand out for perfect on-time delivery records and sub-2-hour response times, reflecting strong operational discipline. Holy Precision demonstrates higher customer retention (36% reorder rate), suggesting consistent quality in complex machining projects involving multiple post-processing techniques. Despite limited revenue transparency, JUNYING METAL and Xinlined maintain competitive positioning through component-level customization and flexible MOQs. Suppliers in Guangdong exhibit broader engineering support, while Chongqing-based firms focus on cost-effective part production for automotive and industrial sectors. For mission-critical components, prioritize suppliers offering full traceability, dimensional inspection reports, and compatibility testing protocols.

FAQs

How to verify machining operations and machine tools supplier reliability?

Assess consistency in delivery performance (target ≥95%), response speed (ideally under 5 hours), and evidence of technical engagement. Request samples accompanied by first-article inspection reports. Validate process control measures, especially for tight-tolerance components requiring repeatable accuracy.

What is the typical lead time for custom machine tool components?

Standard lead times range from 15 to 30 days for CNC-machined parts and fabricated assemblies. Complex tooling or large castings may extend timelines to 45 days. Expedited processing is often available at additional cost, reducing cycle time by up to 30%.

Do suppliers support small-batch or prototype orders?

Yes, most suppliers accommodate low MOQs—some accepting single-piece orders—particularly for CNC-machined prototypes. Pricing adjusts accordingly, with per-unit costs decreasing significantly at volumes above 100 units.

Can I request material certification and surface treatment specifications?

Reputable suppliers provide material test certificates (MTCs) upon request and support various surface treatments including anodizing, zinc plating, and tempered coatings. Confirm compatibility with end-use environments (e.g., corrosion resistance, wear protection).

How does pricing vary across machine tool types?

Benchtop CNC mills start around $8,600 per set, while high-precision vertical machining centers exceed $17,000. Custom tooling and spare parts are priced per unit, ranging from $0.90 for simple pins to over $50 for complex, multi-process components. Volume discounts and bundled service packages are commonly negotiable.