Linear Tooling Cnc Lathe

About linear tooling cnc lathe

Where to Find Linear Tooling CNC Lathe Suppliers?

China remains the dominant hub for linear tooling CNC lathe manufacturing, with key production clusters concentrated in Jiangsu, Liaoning, and Guangdong provinces. These regions host vertically integrated industrial ecosystems that combine precision component sourcing, advanced machining capabilities, and streamlined logistics networks. Wuxi and Dalian have emerged as core centers for high-precision CNC lathe development, supported by localized access to linear guide systems, servo motors, and casting facilities.

The integration of linear tooling into CNC lathes enhances rigidity, accuracy, and dynamic performance—critical for aerospace, automotive, and medical part manufacturing. Suppliers in these clusters benefit from proximity to material suppliers and R&D institutions, reducing component lead times by 20–30% compared to offshore alternatives. Buyers gain access to scalable production environments where full machine builds, including linear guideways and automated tool changers, are completed within single facilities. Typical advantages include MOQ flexibility (down to 1 set), lead times of 30–60 days for standard configurations, and cost efficiency driven by mature supply chains.

How to Choose Linear Tooling CNC Lathe Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, operational reliability, and transaction security:

Technical and Quality Compliance

Verify adherence to international quality standards such as ISO 9001. For export markets, confirm CE marking or equivalent regulatory compliance to ensure smooth customs clearance. Request documentation on spindle runout tolerance (typically ≤0.005mm), positioning accuracy (±0.005mm), and repeatability (±0.003mm) to validate machine precision. Insist on test reports for critical subsystems like linear guides and ball screws.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for dedicated CNC lathe assembly lines

- In-house machining capabilities for bed casting, guideway scraping, and spindle grinding

- Integration of branded components (e.g., Fanuc, Siemens, THK) as indicators of build quality

Cross-reference listed product ranges with response time and on-time delivery metrics to assess operational stability and order management efficiency.

Transaction and Risk Mitigation

Utilize secure payment mechanisms such as escrow services to protect against non-delivery. Prioritize suppliers offering third-party inspection options before shipment. Conduct sample testing to evaluate surface finish quality, thermal stability under continuous operation, and tool change cycle consistency. Confirm packaging standards (marine-grade export crates) and insurance coverage for international shipments.

What Are the Best Linear Tooling CNC Lathe Suppliers?

| Company Name | Location | Main Products | Response Time | On-Time Delivery | Reorder Rate | Price Range (CNC Lathes) | Product Specialization |

|---|---|---|---|---|---|---|---|

| Dalian R&C Machinery Co., Ltd. | Liaoning, CN | CNC Lathes, Custom Automation Systems | ≤3h | 75% | 18% | $12,500–21,600 | Fanuc-controlled models, slant-bed designs |

| Wuxi Pushi Precision Machinery Equipment Co., Ltd. | Jiangsu, CN | CNC Lathe (103 listings) | ≤4h | 100% | - | $25,300–39,800 | High-rigidity slant-bed, multi-functional automatic models |

| SAIFU VIETNAM COMPANY LIMITED | Vietnam | Agricultural Machinery Parts, Transmission Chains | ≤8h | - | - | $60,000–65,000 | High-speed VMC1060B series, 3-axis linear guideway |

| EVER-POWER INDUSTRY PTE. LTD. (x2 entries) | Singapore | Transmission Chains, Speed Reducers, Agricultural Components | ≤1h / ≤4h | - | - | $60,000–65,000 | Linear guideway CNC lathes, interchangeable rolling rails |

Performance Analysis

Dalian R&C Machinery stands out for customization breadth and rapid response, though its 75% on-time delivery rate suggests potential fulfillment risks. Wuxi Pushi demonstrates strong operational reliability with a verified 100% on-time delivery record and a focused product line, indicating specialization in mid-range precision CNC lathes. SAIFU Vietnam and EVER-POWER target premium-tier machines priced above $60,000, likely targeting niche industrial applications requiring high rigidity and long-term durability. However, absence of reorder rate and revenue data limits insight into customer retention. Suppliers listing multiple linear guideway components suggest internal component sourcing capability, potentially improving cost control and repair part availability.

FAQs

What is the typical MOQ for linear tooling CNC lathes?

Most suppliers offer an MOQ of 1 set, enabling low-volume procurement for testing or specialized applications. Bulk orders (5+ units) may qualify for price negotiation and extended warranty terms.

How long does production and delivery take?

Standard models typically require 30–45 days for production. Custom configurations involving specific spindle speeds, tool turret counts, or control systems can extend lead times to 60 days. International shipping via sea freight adds 20–35 days depending on destination.

Can I customize CNC lathe specifications?

Yes, many suppliers support customization of bed length, spindle bore diameter, axis travel, control system (Fanuc, Mitsubishi, Siemens), and tool magazine capacity. Confirmation of in-house engineering teams and provision of CAD/3D models within 72 hours are indicators of robust customization support.

Do suppliers provide installation and training?

Reputable manufacturers often include remote commissioning support and instructional documentation. On-site installation and operator training may be available at additional cost—confirm service scope and travel fee policies prior to order placement.

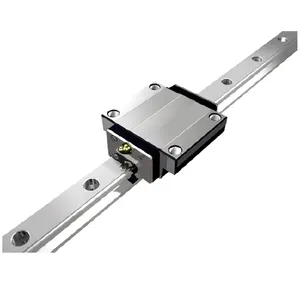

Are spare parts readily available?

Suppliers integrating linear guideways from standardized brands (e.g., THK, HIWIN, ABBA) ensure long-term spare part availability. Verify stock levels of critical components such as linear blocks, ball screws, and drive motors to minimize future downtime.