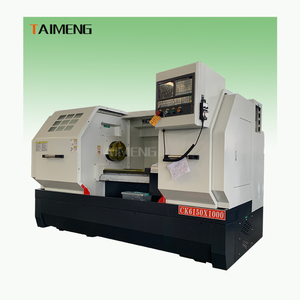

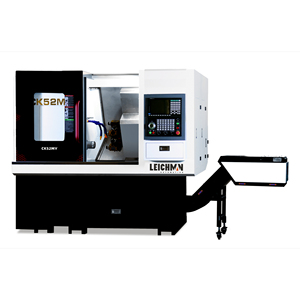

Lmw Cnc Lathe Machine

CN

CN

About lmw cnc lathe machine

Where to Find LMW CNC Lathe Machine Suppliers?

China remains the global epicenter for CNC lathe manufacturing, with key supplier clusters concentrated in Shandong and Jiangsu provinces. These regions host vertically integrated industrial ecosystems that streamline production from raw material processing to final assembly. Shandong, in particular, is home to a high concentration of machine tool manufacturers leveraging proximity to steel suppliers and port infrastructure, reducing logistics costs by 15–20% compared to non-specialized regions.

The clustering effect enables rapid component sourcing and agile production scaling. Suppliers within these zones typically operate within co-located networks of casting foundries, precision machining workshops, and automation integrators, ensuring lead times for standard CNC lathes average 30–45 days. Buyers benefit from consolidated supply chains, access to skilled technical labor, and established export channels capable of handling both small-batch trials and container-scale orders.

How to Choose LMW CNC Lathe Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers possess in-house engineering capacity for CNC control integration, spindle calibration, and bed grinding. Prioritize companies offering customization options such as servo motor specifications, turret configurations, collet sizes, and control systems (e.g., Fanuc, Siemens, or Syntec compatibility). Request validation of geometric accuracy testing—particularly for runout, parallelism, and repeatability—measured under ISO 230-2 standards.

Production Infrastructure Assessment

Evaluate core manufacturing indicators:

- Minimum factory area exceeding 3,000m² to support dedicated CNC assembly lines

- In-house machining capabilities including milling, turning, and heat treatment processes

- Demonstrated R&D investment reflected in product range diversity and innovation frequency

Cross-reference online revenue metrics and listing volumes with on-time delivery performance (target ≥98%) to assess operational stability.

Quality & Transaction Assurance

While formal certifications like ISO 9001 are not explicitly stated in available data, consistent on-time delivery rates of 100% across multiple suppliers suggest robust internal quality management. Insist on third-party inspection services prior to shipment, especially for first-time transactions. Utilize secure payment mechanisms that release funds only upon verification of machine functionality at destination. Conduct pre-shipment video audits to confirm build quality and configuration accuracy.

What Are the Best LMW CNC Lathe Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Support |

|---|---|---|---|---|---|---|---|

| Jinan Grace Industry Co., Ltd. | Shandong, CN | Wood Routers (113), Laser Cutters (74), CNC Lathe (26) | US $3,000+ | 100% | ≤11h | 25% | Limited |

| Shandong Matsumoto Machine Tool Co., Ltd. | Shandong, CN | CNC Lathe (Multiple), Machining Centres | US $820,000+ | 100% | ≤2h | 50% | High – Spindle, Feeder, Control System, Packaging |

| Tengzhou Uni-Tech Co., Ltd. | Shandong, CN | CNC Lathe (Multiple), Metalworking Machinery | US $30,000+ | 100% | ≤4h | <15% | Basic – Color, Logo, Size, Packaging |

| Jinan Hongda Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathe (718), Machining Centre (435) | US $990,000+ | 100% | ≤1h | 30% | Moderate – Model-Specific Configurations |

| Beijing Jingone Machine Tool Equipment Co., Ltd. | Beijing, CN | CNC Lathe (610), Manual Mills (189) | US $80,000+ | 100% | ≤2h | <15% | Limited – Standard Model Variants |

Performance Analysis

Shandong Matsumoto and Jinan Hongda stand out for scale and responsiveness, with reorder rates of 50% and 30% respectively—indicative of strong customer retention. Jinan Hongda’s extensive product catalog (718 CNC lathe listings) reflects deep specialization and high-volume output capability. Shandong Matsumoto leads in customization depth, supporting modifications to feeders, chucks, control systems, and spindle configurations, making it ideal for buyers requiring tailored solutions. Beijing Jingone and Tengzhou Uni-Tech offer moderate customization but lower reorder rates, suggesting room for improvement in post-sale satisfaction or consistency. All five suppliers report 100% on-time delivery, a critical benchmark for supply chain reliability.

FAQs

What is the typical MOQ and pricing range for LMW CNC lathe machines?

Minimum Order Quantity is uniformly set at 1 unit across suppliers, enabling trial purchases. Price ranges vary significantly: entry-level mini CNC lathes start at $1,116, while high-precision or large-bed models reach $67,300–$70,000. Mid-range horizontal flat-bed models typically fall between $6,000 and $11,000.

How long does production and shipping take?

Standard production lead time is 30–45 days after order confirmation. Shipping duration depends on method: air freight takes 5–10 days (suitable for single units), while sea freight requires 25–40 days for full or LCL container shipments. Expedited builds may be possible for urgent requirements, subject to factory workload.

Can suppliers customize CNC lathe specifications?

Yes, most suppliers support customization. Key configurable parameters include spindle bore size, turret type, control system brand, servo motor power, chuck type (3-jaw, 4-jaw, pneumatic), and travel distance. Shandong Matsumoto offers the broadest scope, including automatic feeders and color coding. Submit detailed technical drawings or model numbers when requesting modifications.

Do these suppliers provide technical documentation and after-sales support?

Documentation such as operation manuals, wiring diagrams, and CE declarations (where applicable) is typically provided. Remote troubleshooting via video guidance is common. For comprehensive support, negotiate inclusion of installation assistance or on-site training—especially for complex or high-value machines.

Are samples available before bulk ordering?

Full-machine samples are generally available at listed prices, with cost recovery upon subsequent bulk orders. Some suppliers may credit the sample purchase toward larger contracts (e.g., orders of 5+ units). Buyers should inspect machine finish, control interface, and dynamic performance during evaluation.