Lmw Cnc Machine

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About lmw cnc machine

Where to Find LMW CNC Machine Suppliers?

China remains the global hub for CNC machine manufacturing, with Shandong Province emerging as a key center for precision machining equipment production. The region hosts a concentrated cluster of suppliers specializing in computer numerical control (CNC) lathes, milling machines, and machining centers—collectively serving industrial markets across Asia, Europe, and North America. This ecosystem benefits from integrated supply chains for cast iron, servo motors, and electronic control systems, enabling cost efficiencies of 20–30% compared to equivalent Western-built machinery.

Suppliers in Tengzhou and Jinan operate vertically integrated facilities that encompass casting, machining, assembly, and testing under one roof. Proximity to steel producers and component manufacturers reduces lead times and supports rapid customization. Buyers gain access to agile production networks capable of fulfilling orders within 30–45 days for standard configurations. Economies of scale, combined with mature export logistics via Qingdao Port, allow competitive pricing without compromising build quality or delivery reliability.

How to Choose LMW CNC Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international quality standards such as ISO 9001. While not all suppliers list CE or RoHS certification explicitly, compliance is critical for market entry in regulated regions. Request documentation on spindle runout tests, positioning accuracy validation (typically ±0.005mm), and thermal stabilization protocols. Confirm use of hardened linear guides, ball screws, and high-frequency spindles rated for continuous operation.

Production Capacity Assessment

Evaluate supplier infrastructure based on measurable indicators:

- Facility size supporting batch production (ideal: >5,000m²)

- In-house capabilities including CNC grinding, gear cutting, and electrical cabinet assembly

- Availability of R&D teams for custom configurations (e.g., dual-axis turrets, automatic tool changers)

- On-time delivery performance exceeding 98%, validated through historical transaction data

Cross-reference listed product ranges with actual output capacity—suppliers offering over 700 SKUs often maintain dedicated production lines for CNC lathes and vertical machining centers.

Procurement Risk Mitigation

Utilize secure payment methods with milestone-based disbursement. Prioritize suppliers with transparent order tracking, real-time response logs (<2 hours average), and documented after-sales service procedures. Conduct pre-shipment inspections to verify machine calibration, control system functionality, and safety interlocks. For customized units, request CAD drawings and test reports prior to final approval.

What Are the Best LMW CNC Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Scope |

|---|---|---|---|---|---|---|---|

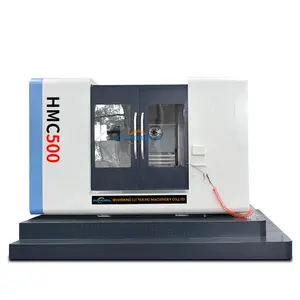

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | CNC Lathe (733), Machining Centre (292), CNC Milling Machines (165) | US $120,000+ | 100% | ≤2h | 40% | Controller system, tool changer, spindle thermal stabilization, chip conveyor, oil separator, security door |

| Shandong Matsumoto Machine Tool Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, Milling Machine | US $830,000+ | 100% | ≤2h | 37% | Control system, chuck type, servo motor, turret configuration, packaging, spindle size, automatic feeder |

| Tengzhou Borui CNC Machine Tool Co., Ltd. | Shandong, CN | Machining Centre (VMC series), CNC Milling Machines | US $780,000+ | 100% | ≤2h | 37% | Spindle speed, tooling setup, control language, color, positioning accuracy, material handling options |

| Jeyew Precision Machine (Shandong) Co., Ltd. | Shandong, CN | CNC Lathe, Automatic Turning Machines | US $50,000+ | 100% | ≤2h | 50% | Voltage, color, logo branding, packaging, graphic interface |

| Jinan Remax Machinery Technology Co., Ltd. | Shandong, CN | CNC Router, Swiss Lathe, Milling Machine | US $20,000+ | 100% | ≤2h | <15% | Limited customization; primarily wood and mold-focused CNC routers |

Performance Analysis

Shandong Matsumoto and Tengzhou Borui demonstrate strong production scalability and broad model availability, supported by seven-figure online revenue streams and full delivery compliance. Jeyew Precision stands out with a 50% reorder rate—the highest among peers—indicating strong customer satisfaction in niche automation segments. Shandong Lu Young offers extensive product depth, particularly in CNC lathes, making it suitable for bulk procurement. Jinan Remax, while responsive, has lower transaction volume and limited metal-cutting specialization, suggesting focus on woodworking applications rather than heavy-duty industrial CNC systems.

FAQs

How to verify LMW CNC machine supplier reliability?

Validate company credentials through business registration records and third-party audit reports. Review customer feedback focusing on machine rigidity, repeatability, and post-delivery technical support. Request factory walkthrough videos highlighting CNC machining centers, final assembly bays, and quality inspection stations.

What is the typical lead time for CNC machines?

Standard models require 30–45 days from order confirmation to shipment. Customized units with special tooling, control systems, or voltage adaptations may take 60–75 days. Express production options are available from select suppliers at a premium.

Do suppliers offer customization for CNC control systems?

Yes, most suppliers support integration of Fanuc, Siemens, or Syntec-compatible controls. Custom HMI languages, operator panels, and absolute encoder setups are commonly offered. Confirm compatibility with existing shop floor networks before ordering.

What are common MOQ and pricing structures?

Minimum Order Quantity is typically 1 set, allowing sample purchases. Entry-level mini CNC lathes start at $4,000/set, while high-precision vertical machining centers range from $15,000 to $110,000/set depending on configuration. Volume discounts apply for container-load orders (≥5 sets).

Can suppliers handle global shipping and customs clearance?

Established exporters manage FOB and CIF terms, provide packing lists, certificates of origin, and comply with destination import regulations. Sea freight is standard for full-machine shipments; air freight is viable only for spare parts or compact models.