Lmw Cnc Machine Price List

CN

CN

CN

CN

About lmw cnc machine price list

Where to Find LMW CNC Machine Suppliers?

China remains the central hub for CNC machine manufacturing, with key supplier clusters concentrated in Shandong and Guangdong provinces. These regions host vertically integrated industrial ecosystems that support rapid prototyping, high-volume production, and cost-efficient component sourcing. Shandong, home to over 40% of China’s heavy-duty CNC lathe and milling machine producers, benefits from proximity to steel and casting supply chains, reducing material costs by up to 18%. Meanwhile, Guangdong-based manufacturers leverage advanced electronics integration and automation expertise, particularly in servo control systems and multi-axis configurations.

The regional specialization enables competitive pricing and scalability. Suppliers in these zones operate facilities averaging 5,000–25,000m², equipped with in-house machining, assembly, and testing lines. This integration allows standard order fulfillment within 30–45 days, with customization lead times extending to 60 days depending on complexity. Buyers gain access to mature networks where spindle units, linear guides, and CNC controllers are sourced locally, ensuring shorter supply cycles and lower MOQs compared to European or North American alternatives.

How to Choose LMW CNC Machine Suppliers?

Evaluating suppliers requires a structured assessment across technical, operational, and transactional dimensions:

Technical Compliance

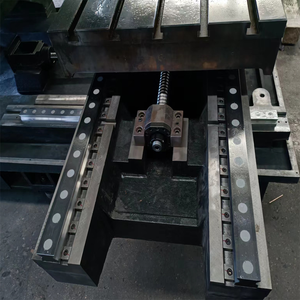

Verify adherence to international quality standards such as ISO 9001 and CE marking, especially for export-bound machinery. Confirm compatibility with industry-standard control systems (e.g., Fanuc, Siemens 808D) and validate spindle specifications—speed range, bore diameter, and power output—against application requirements. For metal-cutting applications, ensure machines are built with hardened linear rails (e.g., HIWIN or THK) and precision ball screws to maintain accuracy over extended operation.

Production Capability Audits

Assess core infrastructure indicators:

- Facility size exceeding 3,000m² to support batch production

- In-house engineering teams capable of customizing work lamp placement, tool changers, automatic chip conveyors, and hydraulic tool posts

- Integrated subsystems including oil mist collectors, coolant separators, and electric turrets

Cross-reference on-time delivery rates (target ≥98%) and response times (≤2 hours) as proxies for operational efficiency and customer service responsiveness.

Transaction Safeguards

Prioritize suppliers with verifiable transaction histories and online revenues exceeding US $700,000 annually, indicating consistent market demand. Utilize secure payment mechanisms and require pre-shipment inspection rights. Request sample units to evaluate build quality, noise levels, and dimensional repeatability before placing bulk orders. Confirm packaging standards and export documentation readiness to avoid customs delays.

What Are the Best LMW CNC Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Scope | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shandong Luzhong Machine Tool Co., Ltd. | Shandong, CN | US $920,000+ | 100.0% | ≤2h | 43% | Spindle units, control systems, linear rails, chip conveyors, hydraulic chucks | $11,000–43,900 | 1 set |

| Shenzhen Guanhong Technology Co., Ltd. | Guangdong, CN | US $810,000+ | 98.0% | ≤2h | 25% | Tool changers, servo motors, cnc controls, spindle options | $2,000–13,000 | 1 set |

| Shandong UMW Technology Co., Ltd. | Shandong, CN | US $700,000+ | 100.0% | ≤2h | 29% | Engraving depth, spindle types, laser modules, material compatibility | $900–3,650 | 1 set |

| Taian Yuzhuo Machinery Co., Ltd. | Shandong, CN | US $70,000+ | 42.0% | ≤8h | 40% | Size, color, logo, packaging, control parameters | $6,200–12,100 | 1 unit |

| Taian Best Machinery Co., Ltd. | Shandong, CN | US $70,000+ | 100.0% | ≤2h | 100% | Material compatibility, size, branding, packaging | $4,000–22,800 | 1 set |

Performance Analysis

Shandong Luzhong Machine Tool stands out for high-end CNC lathes and milling centers, offering extensive customization in servo turrets, fanuc controls, and automatic parts catchers, supported by full compliance tracking and 100% on-time delivery. Shenzhen Guanhong provides mid-range versatility with expandable 4th-axis routers and compact VMC models, ideal for small workshops requiring multi-sided machining. Shandong UMW Technology delivers entry-level CNC routers at aggressive price points ($900–$3,650), suitable for wood and aluminum engraving applications.

Notably, Taian Best Machinery achieves a 100% reorder rate despite lower revenue volume, suggesting strong customer satisfaction through responsive service and reliable performance. However, Taian Yuzhuo's 42% on-time delivery rate indicates potential logistical constraints, warranting closer scrutiny for time-sensitive contracts. Buyers seeking precision metal-cutting equipment should prioritize suppliers offering Siemens or Fanuc-controlled machines with documented spindle runout tests and thermal stability reports.

FAQs

How to verify LMW CNC machine supplier reliability?

Validate certifications through issuing bodies and request factory audit reports or video walkthroughs confirming in-house production capabilities. Analyze customer feedback focusing on machine durability, post-sale technical support, and consistency in dimensional accuracy across batches.

What is the typical lead time for CNC machine orders?

Standard configurations ship within 30–45 days after deposit confirmation. Customized models with specialized spindles or automation features may require 50–60 days. Expedited builds can reduce timelines by 10–15 days at additional cost.

Do suppliers offer customization for industrial CNC machines?

Yes, most suppliers support modifications including control system selection (SYNTEC, Mach3, DSP), spindle speed (6,000–24,000 RPM), tool magazine capacity, and integration of linear guides or automatic chip removal systems. Technical drawings and CAD files are typically required for engineering review.

Can CNC machines be shipped internationally?

All listed suppliers export globally. Confirm FOB terms, container loading specifications (20ft or 40ft), and destination-specific voltage requirements (380V/3P/50Hz standard). Sea freight is recommended for full-machine shipments due to weight and crating needs.

Is sample testing available before bulk procurement?

Sample units are available upon request, often at 30–50% above unit cost, which may be credited toward future orders. Testing should include trial runs with target materials (aluminum, steel, acrylic) to assess surface finish, cutting speed, and positional repeatability.