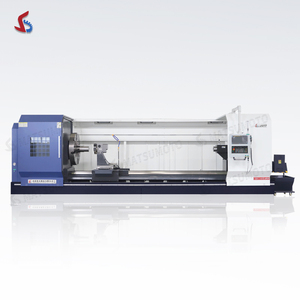

Bfw Cnc Turning Machine Price List

CN

CN

About bfw cnc turning machine price list

Where to Find BFW CNC Turning Machine Suppliers?

China remains the global epicenter for CNC turning machine manufacturing, with key production clusters in Shanghai, Dalian, and Shandong province driving innovation and cost efficiency. These regions host vertically integrated supply chains that support rapid prototyping, high-volume production, and precision machining of metal components. Shanghai and Dalian are recognized for advanced engineering infrastructure and access to skilled technical labor, while Shandong’s industrial base benefits from proximity to raw material sources and port logistics, reducing transportation costs by up to 18% compared to inland regions.

The concentration of CNC lathe specialists in these zones enables streamlined coordination between component suppliers, assembly units, and quality assurance teams—often within a 50-kilometer radius. This ecosystem supports lead times as short as 30 days for standard configurations and allows flexibility for custom modifications. Buyers benefit from economies of scale, with production costs averaging 20–35% lower than equivalent machinery sourced from Europe or North America, particularly for slant-bed, flat-bed, and dual-spindle models under the BFW classification.

How to Choose BFW CNC Turning Machine Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Technical Compliance and Certification

Confirm adherence to international quality standards such as ISO 9001 for quality management systems. For export-bound machinery, CE marking is essential to meet European safety, health, and environmental requirements. Request documentation on spindle accuracy (typically ±0.005mm), surface finish tolerances (Ra ≤1.6μm), and dynamic balancing tests for high-speed operation (up to 6,000 RPM).

Production Capability Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area exceeding 3,000m² to ensure dedicated CNC machining zones

- In-house capabilities including casting, heat treatment, grinding, and final assembly

- Integration of servo-driven tool turrets, automatic feeders, and programmable control systems (Fanuc, Siemens, or equivalent)

- R&D teams supporting customization of travel distance, spindle bore size, and turret configuration

Cross-reference online transaction performance: prioritize suppliers with verified on-time delivery rates above 97% and response times under 2 hours.

Transaction and Quality Assurance Protocols

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Require pre-shipment inspection reports detailing geometric accuracy, noise levels (<75 dB), and vibration testing. For customized orders, insist on sample validation or remote factory audits via video walkthroughs before full-scale production begins.

What Are the Best BFW CNC Turning Machine Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Key Product Range (Price) |

|---|---|---|---|---|---|---|---|

| Shanghai Muwei Electromechanical Equipment Co., Ltd. | Shanghai, CN | Machining Services | 100% | ≤1h | 50% | US $6,000+ | $0.18–19.50 (custom parts, per piece) |

| Crystal Machinery Co., Ltd. | Zhejiang, CN | CNC Lathe | - | ≤13h | - | - | $21,599–84,299 (full machine sets) |

| Dalian Mach Co., Ltd. | Dalian, CN | CNC Lathe, Manual Lathe, Machining Centre | 100% | ≤1h | 20% | US $410,000+ | $28,500–45,800 (slant-bed CNC lathes) |

| Shandong Matsumoto Machine Tool Co., Ltd. | Shandong, CN | Custom CNC Lathes | 100% | ≤2h | 37% | US $830,000+ | $3,930–58,000 (CK series, heavy-duty models) |

| Wuxi Jintong Furnace Co., Ltd. | Jiangsu, CN | CNC Lathe, Metal Casting Machinery | 100% | ≤6h | - | US $140,000+ | $13,900–18,900 (dual-spindle, slant-bed) |

Performance Analysis

Dalian Mach Co., Ltd. and Shandong Matsumoto demonstrate strong technical specialization, offering mid-to-high-end BFW-class CNC turning machines with documented precision and scalability. Shandong Matsumoto stands out with extensive customization options—including pneumatic chucks, servo motor tuning, and multi-axis configurations—supported by a robust reorder rate (37%) and high annual revenue. Dalian Mach focuses on premium slant-bed models (DT40, CLS20) priced between $28,500 and $45,800, ideal for buyers seeking proven industrial reliability. Wuxi Jintong offers competitively priced dual-spindle solutions at $13,900–$18,900, suitable for medium-volume production environments. Crystal Machinery provides high-power models exceeding $80,000, indicating capacity for large-scale industrial deployment despite limited reorder metrics. Shanghai Muwei serves niche demand for low-cost machined components rather than full machine sales, reflecting a service-oriented business model.

FAQs

What is the typical MOQ for BFW CNC turning machines?

Most suppliers set a minimum order quantity (MOQ) of 1 set for complete CNC turning machines. For component-level procurement (e.g., machined shafts or bushings), MOQs range from 2 to 10 pieces depending on complexity.

How long does production and delivery take?

Standard machine orders typically require 30–45 days for manufacturing and pre-shipment preparation. Custom configurations may extend lead times to 60 days. Sea freight adds an additional 20–35 days depending on destination port.

Can suppliers customize CNC turning machines?

Yes, leading manufacturers offer customization of spindle speed, bed type (flat/slant), tool turret count (8–12 stations), control system (Fanuc/Siemens/Mitsubishi), and automation integration (bar feeders, gantry loaders). Design adjustments must be submitted in CAD/DXF format for engineering review.

Are there certification requirements for importing CNC machines?

Import regulations vary by region. CE certification is mandatory for EU markets. Buyers in North America should verify compliance with local electrical and mechanical safety codes. Documentation should include circuit diagrams, calibration certificates, and user manuals in English.

What payment terms are common among suppliers?

Standard terms include 30% advance payment via T/T, with the balance due before shipment. Some suppliers accept Trade Assurance or LC at sight for added security. Escrow arrangements are recommended for first-time transactions.