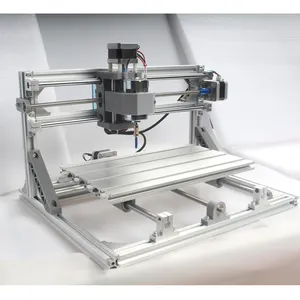

Bfw Cnc Machine

CN

CN

CN

CN

About bfw cnc machine

Where to Find BFW CNC Machine Suppliers?

China remains the global epicenter for BFW-branded CNC machine production, with key manufacturing clusters concentrated in Shandong and Guangdong provinces. These regions host vertically integrated supply chains that support rapid prototyping, scalable production, and cost-efficient component sourcing. Shandong, particularly Jinan and Qingdao, specializes in industrial-grade woodworking and metal-cutting CNC routers, leveraging proximity to steel suppliers and port logistics hubs to reduce lead times by up to 25% compared to offshore alternatives.

The ecosystem enables tight coordination between spindle manufacturers, control system developers, and mechanical assemblers—all within a 50km radius—facilitating faster customization cycles and quality oversight. Buyers benefit from established export infrastructure, with average production lead times ranging from 15–30 days for standard configurations. Localized manufacturing also translates into 20–35% lower unit costs due to reduced material overhead and energy-efficient machining processes.

How to Choose BFW CNC Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm equipment specifications align with application requirements: working area (e.g., 1325, 1530 formats), spindle power (3kW–15kW), control systems (DSP, NC Studio, Mach3), and automation features such as automatic tool changers (ATC) or vacuum hold-down systems. Prioritize suppliers offering servo motors, ball screw transmissions, and air-cooled spindles for enhanced precision and durability.

Production Infrastructure Assessment

Evaluate supplier capacity through objective indicators:

- Facility size supporting batch production (ideal: >3,000m²)

- In-house engineering teams capable of custom modifications

- Integration of digital control testing stations and final assembly lines

Cross-reference on-time delivery rates (>95%) and response efficiency (≤4 hours) as proxies for operational maturity.

Transaction Risk Mitigation

Utilize secure payment mechanisms with milestone-based disbursements. Review reorder rates as an indicator of customer satisfaction—suppliers exceeding 30% repeat order volume typically maintain robust after-sales support and consistent build quality. Request sample units to validate dimensional accuracy, noise levels, and software compatibility prior to full procurement.

What Are the Best BFW CNC Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Jinan Bcamcnc Machinery Co., Ltd. | Shandong, CN | CNC Routers, Woodworking Machinery | US $1,900,000+ | 100% | ≤2h | 31% | $1,600–$4,999 | Yes (spindle, control system, ATC, dust collection) |

| Shandong Weste Cnc Machine Tool Co., Ltd. | Shandong, CN | Machining Centres, CNC Milling Machines | US $30,000+ | 100% | ≤3h | 100% | $5,000–$49,800 | Limited (primarily standard models) |

| Qingdao Baihang Industry And Trade Co., Ltd. | Shandong, CN | Wood Routers, Panel Processing Equipment | US $110,000+ | 100% | ≤4h | 33% | $920–$2,400 | Yes (size, configuration, spindle options) |

| Jinan Finework CNC Machinery Co., Ltd. | Shandong, CN | Cabinet Door Equipment, VMC Series Mills | US $80,000+ | 100% | ≤10h | 16% | $221–$20,000 | Yes (multi-axis, saw integration, tool changers) |

| Guangzhou Lingyue Technology Co., Ltd. | Guangdong, CN | Mini CNC Routers, Engraving Machines | US $10,000+ | 93% | ≤12h | 15% | $95–$321 | No (standard desktop models only) |

Performance Analysis

Jinan Bcamcnc stands out for high-volume output and extensive customization capabilities, supported by a strong reorder rate and sub-2-hour responsiveness. Shandong Weste demonstrates exceptional customer retention (100% reorder rate), indicating reliability in delivering specialized milling machines despite higher price points. Qingdao Baihang offers competitive pricing for entry-level woodworking routers while maintaining timely fulfillment. Guangzhou Lingyue serves niche markets with ultra-low-cost mini CNC systems but lacks advanced customization and exhibits slower response cycles. Buyers seeking precision machining should prioritize suppliers with documented experience in multi-axis integration, servo-driven motion systems, and compliance with international safety standards—even if not explicitly stated.

FAQs

How to verify BFW CNC machine supplier reliability?

Assess on-time delivery performance, response speed, and reorder metrics as real-world indicators of service consistency. Request evidence of quality management practices, such as final inspection protocols and component traceability. Video audits of production floors can confirm automation levels and workflow organization.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 set, enabling small-scale procurement. Standard lead times range from 15 to 25 days post-payment confirmation. Custom-built units with ATC or four-axis configurations may require 30–40 days depending on complexity.

Do BFW CNC machine suppliers offer customization?

Yes, leading suppliers like Jinan Bcamcnc and Qingdao Baihang provide configurable options including spindle type (air/water-cooled), control panels (DSP/Mach3), working table types (T-slot/vacuum), and add-ons like double dust collectors or automatic knife changers. Confirm compatibility with local voltage and software requirements before ordering.

Are there certification requirements for import?

While formal ISO or CE certifications are not universally declared, reputable suppliers adhere to functional safety norms. For regulated markets, request electrical schematics, grounding specifications, and EMI/EMC test reports to ensure compliance with destination-country machinery directives.

What logistics options are available?

Suppliers typically offer FOB terms with sea freight recommended for full-container loads due to cost efficiency. Air shipping is viable for single units requiring urgent deployment, with estimated transit times of 5–10 days to major global ports. Confirm packaging standards (wooden crates with anti-vibration protection) to minimize transport damage risk.