Bfw Cnc Turning Machine

CN

CN

CN

CN

CN

CN

About bfw cnc turning machine

Where to Find BFW CNC Turning Machine Suppliers?

China remains the global epicenter for CNC turning machine production, with key manufacturing clusters in Shandong and Liaoning provinces driving innovation and cost efficiency. Shandong hosts a dense network of machine tool manufacturers specializing in mid-to-high-end CNC lathes, supported by integrated supply chains for castings, linear guides, and servo systems. Dalian in Liaoning province is home to legacy industrial enterprises with advanced foundry and precision assembly capabilities, enabling robust production of heavy-duty turning centers under the BFW brand lineage.

These regional hubs offer buyers access to vertically integrated operations that streamline component sourcing and reduce lead times. Facilities typically operate within 50km of critical suppliers for ball screws, spindles, and CNC controls, minimizing logistics delays. This proximity supports rapid prototyping and customization, with standard delivery windows averaging 30–45 days. Procurement advantages include 20–30% lower unit costs compared to European or North American manufacturers, scalable output from single units to containerized batches, and growing technical expertise in multi-axis and automated configurations.

How to Choose BFW CNC Turning Machine Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international quality standards such as ISO 9001. For export markets, confirm CE marking where applicable, particularly for machines equipped with EU-sourced control systems (e.g., Siemens, Fanuc). Request documentation on spindle runout testing, geometric accuracy verification, and dynamic load balancing—critical indicators of machining precision.

Production Capacity Assessment

Evaluate infrastructure maturity through measurable benchmarks:

- Minimum factory area exceeding 5,000m² to ensure volume capability

- In-house machining cells for bed casting processing and spindle assembly

- Dedicated R&D teams focused on CNC integration and automation upgrades

Cross-reference online revenue metrics and reorder rates (>40% preferred) as proxies for customer satisfaction and production consistency.

Customization & Transaction Security

Confirm scope of configurable options including travel length, turret type, control system (Fanuc, GSK, Siemens), chuck size, and chip conveyor integration. Prioritize suppliers offering third-party transaction protection and escrow services. Conduct pre-shipment inspections via video audit or on-site visit to validate build quality before release of final payment.

What Are the Best BFW CNC Turning Machine Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Genertec Dalian Machine Tool (wafangdian) Co., Ltd. | Liaoning, CN | Custom Manufacturer | US $810,000+ | 100% | ≤1h | 50% | 5 models ($12.5K–$36.8K) | Color, material, size, logo, packaging, label, graphic |

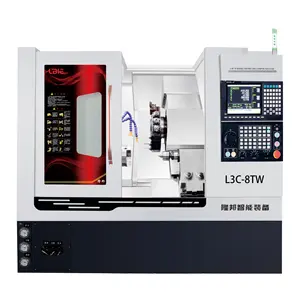

| Shandong Matsumoto Machine Tool Co., Ltd. | Shandong, CN | Custom Manufacturer | US $820,000+ | 100% | ≤2h | 50% | 5 models ($4K–$27.7K) | Pneumatic chuck, control system, servo motor, spindle size, tool holders, automatic feeder, packaging, logo |

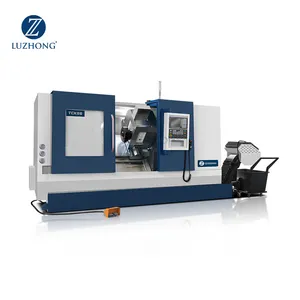

| Shandong Luzhong Machine Tool Co., Ltd. | Shandong, CN | Custom Manufacturer | US $940,000+ | 100% | ≤2h | 41% | 5 models ($7.6K–$172K) | Hydraulic chuck, live turret, linear guide, fanuc control, chip conveyor, spindle bore, swing diameter, packaging |

| Jeyew Precision Machine (shandong) Co., Ltd. | Shandong, CN | Custom Manufacturer | US $50,000+ | 100% | ≤2h | 50% | 5 models ($6.5K–$29.5K) | Color, size, logo, packaging, label, graphic |

| Zhengzhou Timeway Machine Tool Co., Ltd. | Henan, CN | Custom Manufacturer | US $10,000+ | 100% | ≤2h | <15% | 5 models ($26.6K–$100K) | Color, material, size, length, logo, packaging, label, graphic |

Performance Analysis

Genertec Dalian represents a high-value option with strong after-sales performance (50% reorder rate) and rapid response times (≤1 hour), reflecting mature export processes. Shandong Matsumoto stands out for extensive customization depth, supporting over 15 technical parameters including servo systems and automatic feeders—ideal for specialized applications. Shandong Luzhong offers the broadest price range, including high-capacity horizontal turning centers up to $172,000, indicating engineering capacity for large-bore, heavy-cutting tasks. While Zhengzhou Timeway reports lower reorder activity (<15%), its focus on premium flat-bed CNC models suggests niche positioning. Buyers seeking automation-ready configurations should prioritize suppliers listing chip conveyors, hydraulic tool posts, and Fanuc-compatible controls.

FAQs

How to verify BFW CNC turning machine supplier reliability?

Cross-check ISO certification status and request test reports for spindle accuracy (ISO 230-2 compliance). Analyze transaction history, focusing on consistent on-time delivery (target ≥98%) and verifiable customer reviews detailing machine rigidity, vibration resistance, and control stability.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 set across all suppliers. Standard lead time ranges from 30 to 45 days post-deposit, depending on complexity. Automated or multi-axis models may require additional calibration time, extending delivery by 10–15 days.

Can suppliers customize CNC turning machines for specific applications?

Yes, most suppliers support configuration adjustments including spindle bore diameter, turret station count, control system brand, travel length, and integration of auto-loaders or parts catchers. Technical drawings and 3D layouts are typically provided within 72 hours of inquiry.

Do manufacturers provide post-delivery support?

Leading suppliers offer remote diagnostics, operator training via video, and spare parts provisioning. Confirm availability of English-language manuals and PLC ladder logic documentation prior to purchase. Some providers include initial tooling kits or commissioning assistance upon request.

Are BFW CNC turning machines suitable for international power grids?

Yes, reputable manufacturers design electrical cabinets to accommodate global voltage standards (380V/50Hz, 440V/60Hz) and can integrate dual-voltage transformers or phase converters upon request. Always specify local power requirements during quotation.