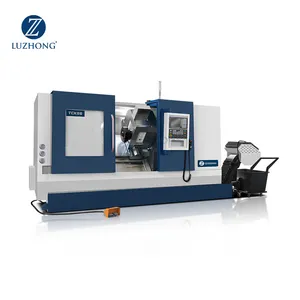

Bfw Turning Cnc Machine

1/4

1/4

1/15

1/15

1/19

1/19

1/33

1/33

1/66

1/66

1/22

1/22

About bfw turning cnc machine

Where to Find BFW Turning CNC Machine Suppliers?

China remains the central hub for BFW turning CNC machine production, with key manufacturing clusters located in Shandong and Fujian provinces. These regions host specialized industrial ecosystems focused on precision machine tools, supported by vertically integrated supply chains for castings, servo systems, and CNC controls. Shandong, in particular, accounts for over 40% of China’s CNC lathe output, leveraging proximity to steel producers and port infrastructure in Qingdao for efficient export logistics.

Suppliers in this region benefit from mature machining networks, enabling rapid prototyping and scalable batch production. The concentration of component manufacturers within 50km allows for reduced lead times—typically 30–45 days for standard configurations—and cost advantages of 15–25% compared to equivalent European or North American-built machines. Buyers gain access to facilities equipped with in-house foundry, heat treatment, grinding, and assembly lines, ensuring tighter quality control across the production cycle.

How to Choose BFW Turning CNC Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional criteria:

Technical Compliance

Confirm adherence to international standards such as ISO 9001 for quality management. For markets requiring regulatory compliance, CE marking is essential for customs clearance in Europe. Request documentation on spindle accuracy (runout ≤0.005mm), positioning repeatability (±0.003mm), and vibration testing reports to validate machine rigidity.

Production Capability Audits

Assess core manufacturing competencies through the following benchmarks:

- Minimum factory area exceeding 5,000m² to support dedicated CNC machining and assembly zones

- In-house development teams responsible for CNC control integration and mechanical design

- On-site metrology equipment (e.g., laser interferometers, CMMs) for calibration and final inspection

Cross-reference delivery performance (target ≥98%) with response time metrics (ideally ≤4 hours) to gauge operational responsiveness.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until post-arrival performance verification. Prioritize suppliers with verifiable export histories and after-sales service frameworks. Conduct pre-shipment inspections via video audit or third-party agencies like SGS or BV to verify build quality and configuration accuracy.

What Are the Best BFW Turning CNC Machine Suppliers?

| Company Name | Location | Verified Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Skymach (Shandong) Intelligent Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | CNC Lathe, Slant Bed, Horizontal Turning | US $110,000+ | 100.0% | ≤2h | 16% |

| Tengzhou Borui CNC Machine Tool Co., Ltd. | Shandong, CN | Custom Manufacturer | Slant Bed CNC Lathe, Multi-Axis Turret | US $780,000+ | 100.0% | ≤2h | 37% |

| Shandong Matsumoto Machine Tool Co., Ltd. | Shandong, CN | Custom Manufacturer | Vertical & Flat Bed CNC Lathes | US $830,000+ | 100.0% | ≤2h | 37% |

| Shandong Fulu Cnc Equipment Co., Ltd. | Shandong, CN | - | CNC Lathe, Machining Centre, EDM | US $200+ | 100.0% | ≤4h | <15% |

| Xiamen Changyuan Jinsheng Technology Co., Ltd. | Fujian, CN | - | Machining Services, Sheet Metal Fabrication | US $700+ | 100.0% | ≤3h | - |

Performance Analysis

Leading suppliers such as Tengzhou Borui and Shandong Matsumoto demonstrate strong market retention, reflected in a 37% reorder rate, indicating consistent product reliability and customer satisfaction. Skymach stands out for its engineering focus on high-precision slant-bed lathes (BR series), with pricing starting at $10,800 for entry-level models. Tengzhou Borui offers competitive pricing on compact BR160L models ($9,900–$16,500), while Shandong Matsumoto provides vertical turning solutions up to $69,000 for heavy-duty applications.

Suppliers based in Shandong dominate technical specialization in CNC turning, offering customization options including turret configuration, servo motor tuning, and digital display interfaces. Fujian-based Xiamen Changyuan Jinsheng operates more as a service provider, focusing on low-cost prototype machining rather than full machine supply. Buyers seeking turnkey CNC lathe solutions should prioritize Shandong-based custom manufacturers with documented R&D capabilities and export experience.

FAQs

How to verify BFW turning CNC machine supplier reliability?

Validate certifications through official registries and request evidence of in-house testing procedures. Review transaction history, including on-time delivery rates and response times. Conduct virtual audits to confirm production line organization, inventory management, and quality control checkpoints.

What is the typical MOQ and lead time?

Most suppliers require a minimum order of one set, with lead times ranging from 30 to 45 days for standard configurations. Customized machines with specific control systems or tooling may extend delivery to 60 days. Prototype units are typically available within 20–25 days.

Can suppliers customize CNC turning machines?

Yes, major manufacturers offer extensive customization: control systems (Fanuc, Siemens, GSK), spindle speed ranges (3,000–6,000 RPM), turret capacity (8–12 stations), feed axes (X/Z travel dimensions), and automation integration (bar feeders, gantry loaders). Technical drawings and 3D models are usually provided within 72 hours of inquiry.

Do suppliers provide after-sales support?

Established manufacturers offer remote diagnostics, operator training, and spare parts supply. Some include commissioning assistance or on-site technician deployment, particularly for large orders. Confirm warranty terms (typically 12 months) and availability of localized service partners.

What are common payment and shipping terms?

Standard payment methods include T/T (30% deposit, 70% before shipment) or Letter of Credit. FOB Qingdao is commonly used for sea freight; air freight options are available for critical components. Full container loads (FCL) are recommended for cost efficiency when shipping complete machines.