Factory Cnc Machine

CN

CN

CN

CN

About factory cnc machine

Where to Find Factory CNC Machine Suppliers?

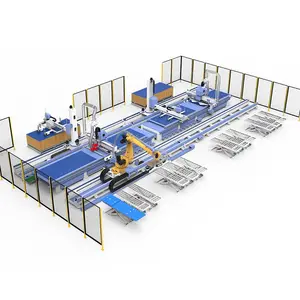

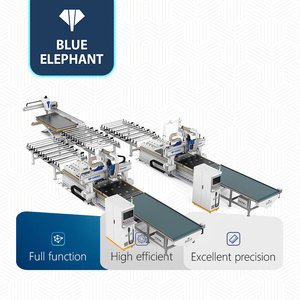

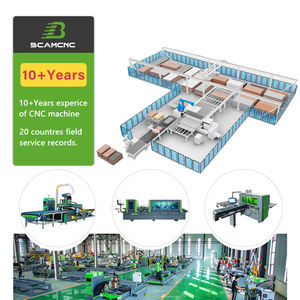

China remains the global epicenter for factory-grade CNC machine manufacturing, with Shandong province emerging as a dominant hub for industrial-scale production lines. The region hosts vertically integrated facilities specializing in woodworking, metal fabrication, and automated furniture panel processing systems. Jinan, in particular, has developed a concentrated cluster of CNC equipment manufacturers leveraging localized supply chains for servo motors, control systems, and vacuum table components—reducing material procurement lead times by 20–25% compared to non-specialized regions.

These suppliers operate within mature ecosystems where engineering, assembly, and testing are conducted in-house, enabling faster turnaround on both standard and customized configurations. Buyers benefit from proximity to component suppliers and logistics networks, with average delivery lead times ranging from 15 to 45 days depending on complexity. Economies of scale allow for competitive pricing across entry-level automation systems and high-end ATC (Automatic Tool Change) nesting routers, while customization flexibility supports integration into existing factory workflows.

How to Choose Factory CNC Machine Suppliers?

Selecting reliable partners requires a structured evaluation of technical, operational, and transactional capabilities:

Technical & Production Verification

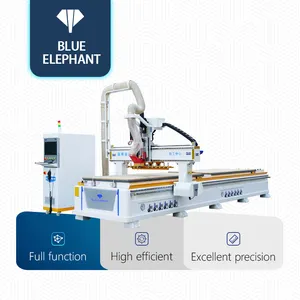

Confirm suppliers possess in-house engineering teams and CNC machining infrastructure for prototyping and quality control. Prioritize companies with documented R&D functions and demonstrated capacity for multi-axis routing, automatic tool changing, and vacuum clamping systems. For industrial applications, verify compatibility with industry-standard control software such as NC Studio or DSP systems.

Quality and Compliance Indicators

While formal ISO 9001 certification is not universally listed, consistent on-time delivery performance (≥97%) and verifiable response times serve as proxy indicators of operational discipline. Suppliers serving EU and North American markets should provide CE marking documentation and comply with machinery safety directives. Request test reports for spindle accuracy, tool change repeatability, and structural rigidity under continuous operation.

Transaction Risk Mitigation

Utilize secure payment mechanisms that align financial release with shipment milestones. Analyze reorder rates as a measure of customer satisfaction—suppliers with reorder rates above 25% indicate strong post-sale support and machine reliability. Conduct video audits of production floors to validate claims about automation levels, inventory management, and quality inspection protocols before placing bulk orders.

What Are the Best Factory CNC Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Value | Price Range (USD) | Verification Status |

|---|---|---|---|---|---|---|---|---|

| Jinan Quick-Fulltek CNC Machinery Co., Ltd. | Wood Routers, ATC CNC Machines, Panel Processing Lines | US $30,000+ | 100% | ≤9h | <15% | 1 set | $33,000–$165,000 | Not specified |

| Jinan Mingshi Machinery Equipment Co., Ltd. | Multifunctional CNC Routers, Nesting Lines, CO2 Laser Systems | US $290,000+ | 100% | ≤1h | 18% | 1 set | $2,350–$10,580 | Custom Manufacturer |

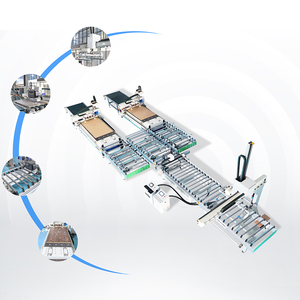

| Jinan TechPro CNC Equipment Co., Ltd. | Furniture Nesting CNCs, Automatic Labeling Systems, ATC Routers | US $560,000+ | 100% | ≤1h | 25% | 1 set | $30,000–$32,000 | Multispecialty Supplier |

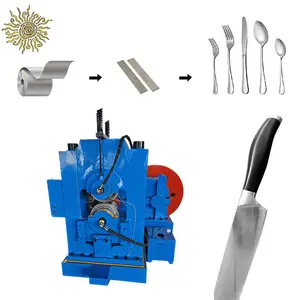

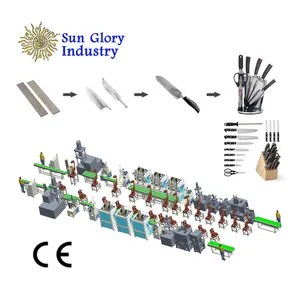

| Guangzhou Shangguan Machinery Co., Ltd. | Metal Knife Manufacturing Lines, CNC Cutlery Production Systems | US $70,000+ | 100% | ≤5h | Not available | 1 set | $8,000–$400,000 | Multispecialty Supplier |

| Jinan Pinmai Cnc Equipment Co., Ltd. | Heavy-Duty ATC Wood Routers, Gantry Milling Systems | US $100,000+ | 50% | ≤4h | 50% | 1 set | $7,000–$13,500 | Custom Manufacturer |

Performance Analysis

Jinan TechPro stands out with the highest online revenue and a 25% reorder rate, indicating consistent product performance and buyer trust in its mid-range industrial CNC systems. Jinan Mingshi offers rapid response times (≤1 hour) and extensive customization options across materials and control systems, making it suitable for buyers requiring agile technical support. Guangzhou Shangguan targets niche metal fabrication applications with high-ticket production lines exceeding $350,000, suggesting specialization in fully automated cutlery manufacturing.

Jinan Pinmai presents a notable case: despite a 50% reorder rate—indicating high end-user satisfaction—its on-time delivery rate is only 50%, signaling potential logistical or production bottlenecks. This discrepancy underscores the need to balance customer retention metrics with fulfillment reliability when selecting partners for time-sensitive deployments.

FAQs

What is the typical MOQ for factory CNC machines?

Minimum order quantities are uniformly set at 1 set across all major suppliers, facilitating pilot purchases and system validation prior to fleet deployment.

How long does production and delivery take?

Standard CNC router systems require 15–30 days for manufacturing and pre-shipment testing. Automated nesting lines with labeling, loading, or ATC features may extend lead times to 45 days. Sea freight adds 25–40 days for international destinations.

Can suppliers customize CNC machines for specific factory layouts?

Yes, most suppliers offer configurable worktable sizes, spindle types (air-cooled or water-cooled), vacuum zoning, and integration with conveyor systems. Technical specifications must include desired dimensions, material types (MDF, plywood, metal sheets), and required automation level for accurate quoting.

Do factory CNC machines come with control software?

Yes, machines typically include DSP, NC Studio, or proprietary control interfaces compatible with CAD/CAM outputs. Buyers should confirm language support (English interface availability) and file format compatibility (DXF, G-code) during procurement.

Are spare parts and after-sales service available internationally?

Established suppliers provide technical documentation, remote diagnostics, and spare part kits. For critical components like spindles and servo drives, request availability timelines and warranty terms (typically 12 months). Video-based training and troubleshooting are commonly offered to reduce downtime.