Lmw Cnc Price List

Top sponsor listing

Top sponsor listing

1/5

1/5

1/7

1/7

1/24

1/24

1/12

1/12

1/21

1/21

1/5

1/5

1/19

1/19

1/11

1/11

1/17

1/17

CN

CN

1/7

1/7

About lmw cnc price list

Where to Find LMW CNC Machine Suppliers?

China remains the global epicenter for CNC machine manufacturing, with key production clusters in Shandong and Shaanxi provinces driving supply chain efficiency. Shandong—home to industrial hubs like Jinan and Qingdao—hosts vertically integrated facilities specializing in high-precision machining centers and CNC lathes, supported by regional steel and automation component suppliers that reduce material costs by 15–20%. Shaanxi’s Xi’an region focuses on advanced multi-axis systems, leveraging local R&D partnerships with technical institutes to enhance machine accuracy and thermal stability.

These industrial ecosystems enable streamlined production from casting to final assembly within compact geographic zones, ensuring faster turnaround times (typically 30–45 days for standard configurations). Buyers benefit from scalable output, localized sourcing of critical components such as spindles and control systems, and access to manufacturers equipped for both bulk procurement and engineered-to-order solutions. The presence of established logistics corridors further supports cost-effective global shipping via sea or rail freight.

How to Choose LMW CNC Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across three core dimensions:

Technical Compliance & Quality Assurance

Confirm adherence to international quality standards such as ISO 9001. For export markets, CE marking is essential for regulatory compliance in Europe, while North American buyers should verify machine safety alignment with ANSI B11 standards. Request documentation on spindle runout testing, axis positioning accuracy (per ISO 230-2), and CNC control system validation (Fanuc, Syntec, or equivalent).

Production Capability Verification

Assess operational scale and engineering capacity through the following indicators:

- Minimum factory footprint of 5,000m² to support dedicated machining and assembly lines

- In-house capabilities including CNC milling, gear processing, and electrical integration

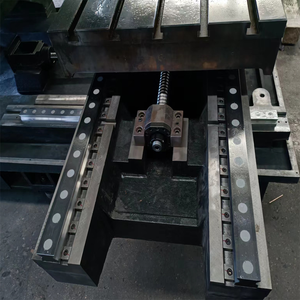

- Integration of thermal stabilization systems, automatic tool changers, and chip conveyors as value-added features

Cross-reference supplier claims with verifiable metrics such as on-time delivery rates (>97%) and reorder frequency to gauge reliability.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services until post-delivery inspection is completed. Prioritize suppliers offering detailed test reports, PLC programming access, and remote diagnostics. Evaluate responsiveness—sub-2-hour average reply time correlates with stronger customer service infrastructure. Sample units should undergo functional testing for axis movement smoothness, tool change cycle consistency, and controller interface usability before full-scale orders.

What Are the Best LMW CNC Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

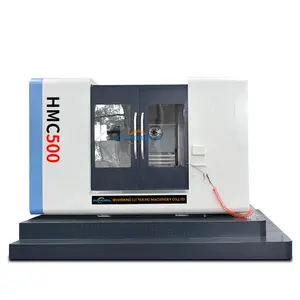

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, CNC Milling Machines | US $120,000+ | 100% | ≤2h | 40% | Rotary table, controller configuration, spindle thermal stabilization, automatic shutdown, tool changer |

| Elite Frontier Enterprises Inc. | N/A | Machining Centre, CNC Lathe, Gas Generation Equipment | Not disclosed | Not available | ≤4h | Not available | Limited customization data; focus on standard models |

| Shaanxi Jingwei Hongbo Cnc Equipment Co., Ltd. | Shaanxi, CN | Machining Centre, CNC Milling Machines | US $100+ | 100% | ≤1h | <15% | 5-axis configurations, absolute sensors, operator panel design |

| Shandong UMW Technology Co., Ltd. | Shandong, CN | CNC Router, Engraving Machines | US $690,000+ | 100% | ≤2h | 29% | Spindle selection, engraving depth, material compatibility, graphic integration |

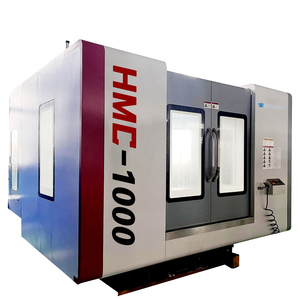

| Shandong HR Machinery Co., Ltd. | Shandong, CN | Machining Centre, CNC Lathe, 5-Axis Systems | US $250,000+ | 100% | ≤2h | 50% | Control system (Syntec), color, packaging, test reporting, PLC integration |

Performance Analysis

Shandong HR Machinery stands out with a 50% reorder rate and robust customization options, indicating strong customer retention and engineering flexibility. Shandong Lu Young offers comprehensive feature sets including thermal stabilization and dual-chip screw systems, ideal for precision applications. Despite lower reported online revenue, Shaanxi Jingwei Hongbo excels in rapid response (≤1h) and advanced 5-axis technology, suggesting niche specialization. Shandong UMW leads in transaction volume (US $690,000+), reflecting consistent market demand for its router-focused product line. Elite Frontier provides competitively priced entries but lacks performance transparency, presenting higher due diligence requirements.

FAQs

How to verify LMW CNC machine supplier reliability?

Validate certifications through issuing bodies and request audit trails covering raw material sourcing, machining tolerances, and final inspection protocols. Analyze customer reviews focused on machine uptime, control system stability, and technical support responsiveness. Video audits of production floors can confirm in-house processing capabilities.

What is the typical lead time for CNC machines?

Standard models are typically delivered within 30–45 days after order confirmation. Custom-configured units with specialized controllers or multi-axis setups may require 60–75 days, depending on complexity and component availability.

Do suppliers offer customization for CNC control systems?

Yes, leading suppliers provide configurable options including Fanuc, Syntec, and Siemens controls. Additional customizations include operator panels, tool changers, oil separators, and thermal compensation systems to meet specific production environments.

What are common MOQ and pricing structures?

Most suppliers list a minimum order quantity of 1 unit, with prices ranging from $4,600 for basic CNC lathes to over $70,000 for 5-axis machining centers. Volume discounts apply for container-load orders (8–12 units), improving per-unit economics.

Can CNC machines be shipped internationally?

All listed suppliers support global exports. Confirm Incoterms (FOB, CIF) and ensure compliance with destination country regulations regarding electrical safety and machinery import codes. Sea freight is recommended for heavy equipment to minimize transportation costs.