Bfw Cnc Machine Price In India

CN

CN

About bfw cnc machine price in india

Where to Find CNC Machine Suppliers for the Indian Market?

China remains the dominant global hub for CNC machine manufacturing, with key industrial clusters in Shandong and Qingdao offering competitive advantages for buyers targeting the Indian market. These regions host vertically integrated production ecosystems specializing in woodworking, metal cutting, and multi-axis machining systems. Suppliers in Shandong benefit from proximity to steel suppliers and port logistics, reducing material costs by 15–20% and enabling faster export cycles. Qingdao-based manufacturers focus on compact, cost-efficient CNC routers ideal for small-to-medium Indian workshops requiring entry-level automation.

The concentration of component suppliers, control system integrators, and assembly facilities within 50km radii supports rapid prototyping and scalable order fulfillment. Buyers can expect lead times of 30–45 days for standard configurations, with localized supply chains contributing to 20–30% lower pricing compared to European or domestic Indian suppliers. This infrastructure is particularly advantageous for procurement of BFW-category machines—typically referring to versatile, mid-range CNC routers used in furniture, signage, and panel processing industries.

How to Choose Reliable CNC Machine Suppliers?

Selecting a qualified supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international quality standards such as ISO 9001. For CNC machinery, confirm compatibility with common control systems (e.g., NC Studio, DSP) and spindle power ratings (ranging from 3kW to 6kW in mid-tier models). Machines intended for Indian conditions should support voltage stabilization and dust collection features due to variable power supply and workshop environments.

Production Capability Assessment

Evaluate core manufacturing indicators:

- Facility size exceeding 3,000m² indicating volume capacity

- In-house engineering teams capable of customization (e.g., worktable size, ATC integration)

- On-time delivery performance above 97%

- Response time under 6 hours for technical inquiries

Cross-reference product listings with verified revenue data and reorder rates to assess business stability and customer satisfaction.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services until post-delivery inspection. Prioritize suppliers offering sample testing—critical for validating cutting precision, software interface usability, and structural rigidity. Request demonstration videos or remote factory audits to verify production claims before committing to bulk orders.

What Are the Leading CNC Machine Suppliers for India?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization |

|---|---|---|---|---|---|---|---|---|

| Qingdao Baihang Industry And Trade Co., Ltd. | Wood Routers, Saw Machines, Planers | $920–2,400 | 1 set | 100% | ≤4h | 33% | US $110,000+ | Limited |

| Shandong Xunke Cnc Machine Co., Ltd. | 3-Axis & 4-Axis CNC Routers | $1,500–4,890 | 1–2 pieces | 100% | ≤2h | <15% | US $170,000+ | Extensive |

| Dongguan BH Mechanical Equipment Company Limited | Used CNC Milling, VMC, Turret Machines | $1,900–23,000 | 1 set | 100% | ≤6h | <15% | US $50,000+ | None |

| Jinan Hongda Cnc Equipment Co., Ltd. | Machining Centers, CNC Lathes, EDM | $1,200–15,000 | 1 set | 100% | ≤1h | 30% | US $950,000+ | Moderate |

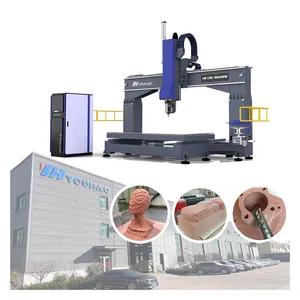

| Jinan Mingshi Machinery Equipment Co., Ltd. | 5-Axis ATC, Wood Carving, Alucobond Routers | $1,980–10,250 | 1 set | 100% | ≤1h | 21% | US $300,000+ | High |

Performance Analysis

Jinan Hongda stands out with the highest online revenue and fastest response time, reflecting strong operational efficiency and export readiness. Its broad price range accommodates both entry-level and high-precision buyers in India. Shandong Xunke and Jinan Mingshi offer extensive customization options, including plasma cutters, oscillating knives, and rotary attachments—ideal for specialized fabrication units. Qingdao Baihang provides competitively priced entry-level routers starting at $920, suitable for startups. Dongguan BH specializes in refurbished industrial-grade milling and VMC machines, presenting a cost-effective alternative for budget-conscious Indian manufacturers seeking higher tonnage equipment without new-machine premiums.

FAQs

How to verify CNC machine supplier reliability?

Cross-check ISO certification status and demand documentation for spindle, drive system, and control board sourcing. Analyze supplier transaction history, focusing on consistent on-time delivery records and verifiable customer feedback related to after-sales service and machine durability.

What is the typical lead time for CNC machine orders?

Standard models require 20–35 days for production and pre-shipment inspection. Customized units with ATC or multi-head configurations may take 45–60 days. Air freight adds 5–10 days; sea freight to Indian ports averages 18–25 days depending on origin port and customs clearance.

Do suppliers support global shipping to India?

Yes, most established manufacturers handle FOB and CIF shipments to major Indian ports like Mumbai, Chennai, and Nhava Sheva. Confirm inclusion of packaging reinforcement, marine insurance, and compliance with Indian import codes (HSN 8456) for CNC machinery.

Are samples available before bulk purchase?

Sample policies vary. Some suppliers offer test-cut video demonstrations or small prototype runs at partial cost. Full machine samples are typically provided only for customized models, with fees applicable toward final orders exceeding two units.

What customization options are commonly offered?

Buyers can request modifications in working area (e.g., 1300x2500mm), spindle power (3–9kW), vacuum table configuration, tool changers (ATC), and software language (English, Hindi-compatible interfaces). Integration with CAD/CAM workflows and support for materials like MDF, acrylic, aluminum, and stone enhance versatility for Indian fabricators.