Lmt Cnc Machine

CN

CN

CN

CN

CN

CN

About lmt cnc machine

Where to Find LMT CNC Machine Suppliers?

China remains the global epicenter for CNC machine manufacturing, with key production clusters in Liaoning, Shanghai, and Guangdong provinces driving innovation and cost efficiency. Dalian in Liaoning Province hosts a concentrated base of heavy industrial machinery manufacturers, specializing in high-precision vertical and horizontal machining centers. Shanghai’s advanced mechatronics ecosystem supports compact, high-speed CNC lathes ideal for light-duty and dental applications. Meanwhile, Foshan in Guangdong has emerged as a hub for entry-level and miniaturized CNC systems, leveraging regional automation supply chains to deliver competitively priced solutions.

These industrial zones benefit from vertically integrated production networks—spanning casting, linear guide assembly, spindle manufacturing, and CNC control integration—enabling rapid prototyping and scalable output. Buyers gain access to mature infrastructures where component sourcing, precision machining, and final assembly occur within tightly coordinated geographic radii. This localization reduces lead times to 30–45 days for standard configurations and lowers production costs by 20–30% compared to Western counterparts. The region's export-ready logistics infrastructure further facilitates global distribution, particularly for containerized shipments of larger machining centers.

How to Choose LMT CNC Machine Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Confirm adherence to international quality standards such as ISO 9001. For equipment destined for European or North American markets, CE marking is essential for regulatory compliance. Request documentation on spindle accuracy (±0.005mm typical), ball screw precision (C3 class minimum), and CNC system specifications (Fanuc, Siemens, or equivalent). Verify inclusion of critical safety features and electromagnetic compatibility testing.

Production Capability Assessment

Evaluate core manufacturing competencies through the following criteria:

- Facility size exceeding 5,000m² indicating volume capacity

- In-house machining capabilities including grinding, milling, and heat treatment

- Dedicated R&D teams supporting customization (e.g., multi-axis upgrades, tool changers)

- Integration of linear guides, servo motors, and high-frequency spindles (up to 12,000 rpm)

Cross-reference on-time delivery performance (target: 100%) and response time metrics (≤4 hours) as indicators of operational reliability.

Transaction Security & Procurement Safeguards

Utilize secure payment mechanisms such as third-party escrow until post-delivery inspection. Prioritize suppliers offering Trade Assurance or equivalent protection programs. Conduct pre-shipment inspections via third-party auditors to validate machine calibration, structural rigidity, and functional performance. Request sample units for benchmarking against industry standards like ISO 230-2 for positional accuracy.

What Are the Best LMT CNC Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Wmt Cnc Industrial Co., Ltd. | Liaoning, CN | Custom Manufacturer | US $3.1M+ | 100% | ≤4h | <15% | Spindle bore, work light, packaging, logo, swing rest, bed width |

| Shanghai Sumore Industrial Co., Ltd. | Shanghai, CN | Multispecialty Supplier | US $120K+ | 100% | ≤3h | 25% | Color, material, size, logo, packaging |

| Genertec Dalian Machine Tool (wafangdian) Co., Ltd. | Liaoning, CN | Custom Manufacturer | US $710K+ | 100% | ≤1h | 42% | Color, material, size, logo, packaging |

| Foshan Shunde Xinlongke Automation Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $30K+ | 100% | ≤4h | 33% | Axis count, spindle size, CNC system, hydraulic chuck, ball screw |

| Dalian Jori Co., Ltd. | Liaoning, CN | Custom Manufacturer | US $320K+ | 100% | ≤2h | 40% | 5-axis, spindle speed, tool holder, cooling system, CNC control |

Performance Analysis

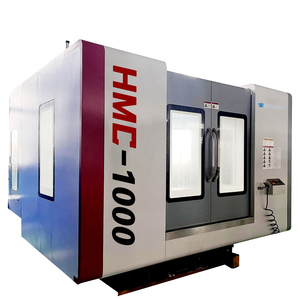

Genertec Dalian Machine Tool stands out with the highest reorder rate (42%) and fastest average response time (≤1 hour), indicating strong customer satisfaction and operational responsiveness. Dalian Jori Co., Ltd. demonstrates robust engineering flexibility, offering 5-axis integration and high-speed spindle options up to 12,000 rpm. Wmt Cnc Industrial provides extensive customization depth, including specialized accessories like steady rests and machine stands, despite a lower reorder rate suggesting potential gaps in after-sales engagement. Shanghai-based suppliers exhibit agility in serving niche markets such as dental and mini-lathe applications, while Dalian and Foshan manufacturers dominate mid-range and industrial-grade VMCs and HMCs. All top-tier suppliers maintain 100% on-time delivery records, underscoring reliable fulfillment processes. For high-volume procurement, prioritize manufacturers with proven experience in exporting large-format machining centers and documented quality management systems.

FAQs

How to verify LMT CNC machine supplier reliability?

Validate certifications (ISO, CE) through issuing bodies and request factory audit reports. Analyze verifiable transaction histories, focusing on order fulfillment consistency, dispute resolution outcomes, and customer feedback on machine durability and technical support.

What is the typical lead time for CNC machines?

Standard models require 30–45 days for production and preparation. Custom configurations involving multi-axis systems or specialized tooling may extend lead times to 60–75 days. Air freight adds 5–10 days; sea freight ranges from 20–40 days depending on destination.

Do suppliers offer customization for CNC machines?

Yes, most manufacturers support modifications including axis count (3-axis to 5-axis), spindle type (BT40/BT50), CNC control systems (Fanuc, Syntec), and physical attributes (color, size, packaging). Engineering collaboration is typically required for non-standard configurations.

What are common MOQ and pricing structures?

Minimum Order Quantity is typically 1 set or unit. Entry-level mini CNC lathes start at $1,350, while industrial 5-axis vertical machining centers exceed $350,000. Volume discounts apply for orders of 5+ units, particularly for standardized models.

Can suppliers handle global shipping and customs clearance?

Established exporters manage international logistics under FOB, CIF, or DDP terms. Confirm compliance with import regulations in target markets, especially for electrical components and machinery safety standards. Most suppliers partner with freight forwarders to streamline documentation and port handling.