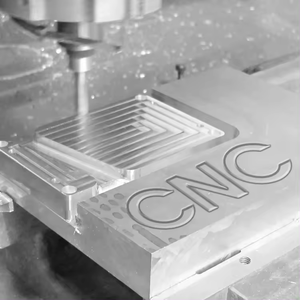

Cnc And Precision Machining

Top sponsor listing

Top sponsor listing

CN

CN

About cnc and precision machining

Where to Find CNC and Precision Machining Suppliers?

China remains a global leader in precision machining manufacturing, with key industrial hubs concentrated in Guangdong Province—particularly Shenzhen and Dongguan. These regions host vertically integrated ecosystems combining advanced CNC processing infrastructure, material sourcing networks, and rapid prototyping capabilities. The proximity to ports like Shekou and Yantian enables efficient export logistics, reducing transit times by 10–15 days compared to inland clusters.

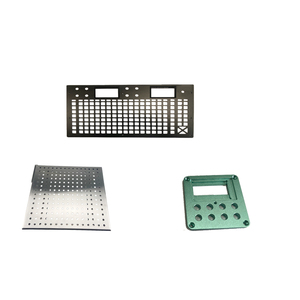

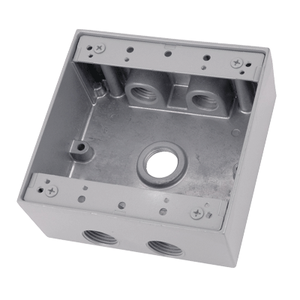

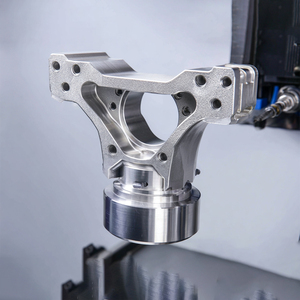

Suppliers in this region specialize in high-precision components for aerospace, medical devices, automotive, and industrial automation sectors. Facilities typically feature multi-axis CNC lathes, milling centers, wire EDM, and grinding equipment capable of tolerances down to ±0.005 mm. Integrated sheet metal fabrication lines support secondary operations including laser cutting, bending, welding, and surface treatments such as anodizing and plating. This co-location of services allows for end-to-end production under one roof, minimizing supply chain complexity and improving turnaround consistency.

How to Choose CNC and Precision Machining Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm access to 4-axis and 5-axis CNC machines for complex geometries. Evaluate whether suppliers offer full-service engineering support—including GD&T interpretation, DFM analysis, and drawing validation. For regulated industries, ensure compliance with ISO 9001:2015 or AS9100 standards is documented and actively maintained.

Production Capacity Assessment

Key benchmarks include:

- Facility size exceeding 2,000m² indicating scalable operations

- In-house tooling and mold-making capabilities to reduce dependency on external vendors

- Dedicated quality control stations equipped with CMMs, optical comparators, and surface roughness testers

Cross-reference machine inventory with online listing diversity (e.g., ≥50 active product listings in machining services) as an indicator of process maturity.

Transaction Risk Mitigation

Prioritize suppliers with verified performance metrics: on-time delivery rates ≥96%, response times ≤3 hours, and reorder rates above 25%. Use secure payment mechanisms tied to milestone inspections. Request first-article inspection reports (FAIR) and batch QC documentation prior to shipment. Pre-shipment sampling is critical—benchmark dimensional accuracy against ISO 2768-mK or customer-specific tolerances before scaling volume.

What Are the Best CNC and Precision Machining Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Scope |

|---|---|---|---|---|---|---|---|

| Shenzhen Runze Metal Technology Co., Ltd. | Shenzhen, CN | Sheet Metal Fabrication (574), Machining Services (70) | 96% | ≤3h | 50% | US $1.8M+ | Anodization, stamping, die casting, assembly, rubber coating |

| Shenzhen Chuangyi Precision Hardware Co., Ltd. | Shenzhen, CN | Machining Services (256), Sheet Metal Fabrication (48) | 100% | ≤1h | <15% | US $20K+ | Material selection, labeling, packaging, graphic integration |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Vietnam-based, CN-linked operations | Machining Services (872), Sheet Metal (53), Casting (39) | 100% | ≤2h | - | US $10K+ | Titanium/stainless steel machining, heat treatment, Moulds |

| Dongguan Shufengyuan Precision Manufacturing Co., Ltd. | Dongguan, CN | Machining Services (312) | 100% | ≤2h | - | - | 4-axis/5-axis CNC turning and milling |

| Perfect Goods Prototype Co., Ltd. | Shenzhen, CN | Machining Services, Custom Prototypes | 96% | ≤3h | 26% | US $560K+ | Brass, aluminum, SS304, lead-free materials, wooden inserts |

Performance Analysis

JINKE VIET NAM leads in service breadth with over 870 machining listings, suggesting robust production scalability and diversified material expertise. Shenzhen Chuangyi stands out for responsiveness (≤1h average reply time) and perfect on-time delivery, though lower reorder rates indicate potential gaps in post-sale engagement. Shenzhen Runze demonstrates strong customer retention (50% reorder rate) supported by extensive customization options across finishing, packaging, and sub-assembly. Dongguan Shufengyuan specializes in high-precision multi-axis work, ideal for complex prototypes and low-volume batches. Perfect Goods excels in niche material handling and rapid prototyping, serving clients requiring tight-tolerance machined parts from exotic alloys.

FAQs

How to verify CNC machining supplier reliability?

Validate certifications through accredited bodies. Request facility videos highlighting CNC workcells, QC checkpoints, and raw material storage. Analyze historical transaction data focusing on delivery consistency, dispute resolution speed, and feedback related to dimensional accuracy and surface finish adherence.

What is the typical lead time for custom CNC parts?

Standard lead times range from 15–25 days for prototype batches. Production runs (≥1,000 units) may require 30–45 days depending on complexity and finishing requirements. Rush services are available at select facilities, reducing timelines by 30–50% with expedited fees.

Do suppliers support international shipping and customs clearance?

Yes, most established suppliers manage door-to-door logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm that export documentation includes material certificates, packing lists, and test reports compliant with destination regulations.

Are free samples available for CNC machined components?

Sample policies vary. Some suppliers offer paid samples refundable against future orders. Typical sample costs cover 40–70% of unit production expenses, especially for small-run 5-axis or titanium parts. Free samples are generally limited to standardized components.

What customization options are commonly offered?

Suppliers routinely support custom materials (aluminum 6061/7075, stainless steel 304/316, brass, PEEK), surface treatments (anodizing, powder coating, passivation), laser engraving, and kitting/packaging configurations. Advanced providers also integrate overmolding, adhesive bonding, and final assembly services.