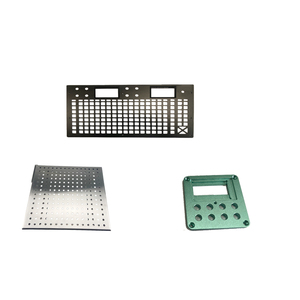

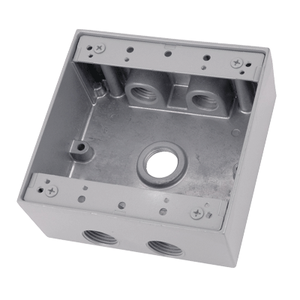

Precision Machining Cnc

Top sponsor listing

Top sponsor listing

1/15

1/15

1/4

1/4

1/16

1/16

1/18

1/18

About precision machining cnc

Where to Find Precision Machining CNC Suppliers?

China remains the global epicenter for precision machining CNC manufacturing, with key industrial hubs in Guangdong and Shandong provinces driving innovation and scale. Guangdong, particularly the Shenzhen-Dongguan corridor, hosts over 70% of high-precision CNC service providers specializing in tight-tolerance components for aerospace, medical, and automation sectors. Shandong’s Tengzhou cluster focuses on CNC machine tool production, leveraging decades of mechanical engineering expertise and integrated supply chains for castings, spindles, and control systems.

These regions offer vertically aligned ecosystems where raw material sourcing, heat treatment, CNC milling/turning, surface finishing, and assembly occur within compact geographic zones—reducing lead times by up to 40% compared to decentralized models. Buyers benefit from rapid prototyping (typically 5–7 days), scalable batch production, and access to advanced capabilities such as 5-axis machining, wire EDM, and anodizing. Average unit costs are 25–35% lower than equivalent Western suppliers due to optimized labor efficiency and localized component networks.

How to Choose Precision Machining CNC Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Compliance

Confirm adherence to ISO 9001 or IATF 16949 standards as baseline quality assurance. For regulated industries (e.g., aerospace, automotive), validate compliance with AS9100 or PPAP documentation. Insist on dimensional inspection reports (CMM, GD&T) and material traceability for critical parts. CE marking is essential for machine tool exporters shipping to European markets.

Production Infrastructure Assessment

Evaluate core competencies through verifiable metrics:

- In-house CNC equipment including multi-axis machining centers, Swiss lathes, and grinding machines

- Secondary processing capabilities: anodizing, plating, welding, stamping, die casting, and assembly

- Digital workflow integration: CAD/CAM compatibility, DFM feedback, and real-time production tracking

Prioritize suppliers with response times under 3 hours and on-time delivery rates exceeding 97%, indicators of robust internal coordination.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services tied to shipment milestones. Request sample batches before full-scale orders to verify dimensional accuracy and surface finish consistency. Analyze reorder rates as a proxy for customer satisfaction—suppliers with rates above 35% demonstrate reliable performance and service quality.

What Are the Best Precision Machining CNC Suppliers?

| Company Name | Type | Main Services | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Shenzhen Runze Metal Technology Co., Ltd. | Custom Manufacturer | Sheet Metal Fabrication, Machining, Casting, Assembly | Material, size, color, logo, packaging, drawings, rubber coating | 97% | ≤3h | US $1,700,000+ | 46% |

| Tengzhou Borui CNC Machine Tool Co., Ltd. | Custom Manufacturer | CNC Milling Machines (3-axis to 5-axis), VMC Series | Spindle speed, control system, tooling, dimensions, language interface | 100% | ≤2h | US $890,000+ | 39% |

| Ald Precision Manufacturing Co., Ltd. | Manufacturer | Machining, Casting, Sheet Metal, Moulds, Fabrication | Design, material, size, logo, graphic elements | 100% | ≤1h | US $1,000+ | - |

| FERSCH | Manufacturer | Precision Turning, Machined Components, Pipe Fittings | Stainless steel alloys, fasteners, hydraulic parts, OEM designs | - | ≤25h | - | - |

| AVOS AUTO EXPORTS LIMITED | Trading Company | Distribution of Haas, GRO.B, LEYOO CNC Machines | Limited customization; primarily resale of branded units | - | ≤4h | - | - |

Performance Analysis

Shenzhen Runze leads in service breadth and commercial traction, evidenced by its high online revenue and 46% reorder rate—indicative of strong client retention in custom fabrication. Tengzhou Borui excels in machine tool reliability with 100% on-time delivery and sub-2-hour response times, ideal for buyers seeking production-grade CNC mills. Ald Precision stands out for responsiveness (≤1h) and full-spectrum machining services despite limited public financial data. In contrast, FERSCH and AVOS AUTO exhibit longer response windows and lack reorder metrics, suggesting less mature buyer engagement processes. Notably, AVOS AUTO operates as a trading entity, offering off-the-shelf machines without direct manufacturing control—increasing supply chain opacity.

FAQs

How to verify precision machining CNC supplier reliability?

Request copies of quality management certifications (ISO, IATF) and cross-reference them with issuing bodies. Conduct virtual or physical factory audits to confirm CNC equipment ownership, inspection protocols (e.g., CMM usage), and workforce training records. Analyze transaction history for consistent order fulfillment and after-sales support resolution.

What is the typical lead time for CNC machined parts?

Standard prototypes take 5–7 days; production batches range from 15–30 days depending on complexity and volume. CNC machine tools (e.g., VMC850) require 30–45 days for manufacturing and testing prior to shipment.

Do suppliers support low-volume or prototype orders?

Yes, most reputable manufacturers accept MOQs as low as 1 unit, particularly for machined components. Unit pricing decreases significantly at volumes exceeding 500 pieces due to setup amortization.

Can CNC suppliers handle full project lifecycle management?

Top-tier providers offer end-to-end solutions—from design optimization (DFM) and material selection to finishing, assembly, and drop-shipping. Confirm availability of technical engineers for drawing validation and iterative feedback during production.

What materials are commonly used in precision CNC machining?

Aluminum (6061, 7075), stainless steel (303, 304, 316), carbon steel, brass, titanium, and engineering plastics (POM, PEEK) are standard. Surface treatments include anodizing, passivation, zinc plating, and powder coating.