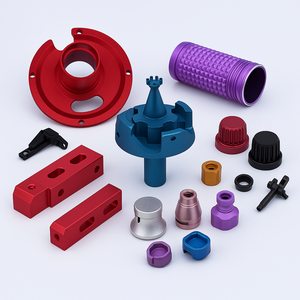

Cnc Precision Machining Components

Top sponsor listing

Top sponsor listing

About cnc precision machining components

Where to Find CNC Precision Machining Components Suppliers?

China remains the global epicenter for CNC precision machining components, with key manufacturing clusters in Jiangsu and Guangdong provinces offering robust industrial ecosystems. These regions host vertically integrated supply chains that encompass raw material sourcing, advanced CNC processing, surface treatment, and logistics—enabling rapid prototyping and scalable production. Jiangsu-based suppliers benefit from proximity to Shanghai’s international ports, reducing export lead times by 10–15% compared to inland counterparts.

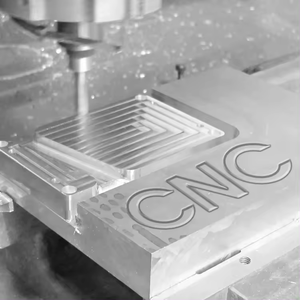

The concentration of specialized machinery, skilled technicians, and ancillary services within 50km radii supports high-efficiency operations. Buyers can expect typical lead times of 15–30 days for custom orders, depending on complexity and volume. Localized tooling and material networks reduce component costs by 20–35% versus Western manufacturers, while maintaining tight tolerances (±0.005mm) across milling, turning, and multi-axis machining processes. The widespread adoption of 4- and 5-axis CNC systems enables complex geometries and reduced setup cycles, enhancing repeatability for high-mix, low-volume production runs.

How to Choose CNC Precision Machining Components Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm access to multi-axis CNC machines (4-axis and above), Swiss lathes, and wire EDM for complex part geometries. Prioritize suppliers with in-house design engineering support for DFM (Design for Manufacturability) feedback. Materials expertise should include aluminum alloys (6061, 7075), stainless steel (303, 316), titanium, brass, and select engineering plastics. Surface treatment capabilities such as anodizing, plating, passivation, and powder coating indicate process maturity.

Quality Management Systems

While formal ISO 9001 certification is not universally listed in available data, consistent on-time delivery rates above 90% and verifiable reorder rates serve as proxies for quality control discipline. Demand documented inspection protocols including first-article inspection (FAI), CMM reports, and batch traceability. For regulated industries (medical, aerospace, automotive), request evidence of PPAP or APQP compliance.

Production Scalability & Responsiveness

Evaluate response time and order flexibility:

- Response times ≤1 hour correlate with higher service engagement and faster quotation turnaround

- Minimum order quantities (MOQ) ranging from 1–10 pieces enable agile prototyping and small-batch validation

- Monthly online revenue exceeding US $10,000 suggests established digital commerce infrastructure and customer volume

Transaction Risk Mitigation

Leverage secure payment mechanisms and insist on sample validation before full production. Use detailed RFQs specifying material certifications, dimensional tolerances, surface finishes, and packaging requirements. Conduct virtual factory audits via video tours to verify equipment conditions and workflow organization. Track reorder rates as a behavioral indicator of customer satisfaction and product reliability.

What Are the Best CNC Precision Machining Components Suppliers?

| Company Name | Main Services | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Customization Options | MOQ Flexibility |

|---|---|---|---|---|---|---|---|

| Changzhou Naite Metal Technology Co., Ltd. | Machining, Casting, Sheet Metal | 85% | ≤1h | 40% | US $30,000+ | Color, material, size, logo, packaging | 10 pcs (standard) |

| Bozhan Precision Hardware INC | Sheet Metal, Machining, Casting, Forging | - | ≤2h | - | - | Limited public data | 10–500 pcs |

| DIMUD TECHNOLOGY CO., LIMITED | Machining, Moulds, Sheet Metal | 66% | ≤2h | <15% | US $10,000+ | 5-axis, prototype services | 1 pc |

| SkyReach Intelligent MFG Limited | Machining, Sheet Metal | 78% | ≤3h | <15% | US $30,000+ | Color, material, size, logo | 1 pc |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Machining, Sheet Metal, Casting, Moulds | 100% | ≤1h | - | US $10,000+ | Titanium, precision turning/milling | 1 pc |

Performance Analysis

JINKE VIET NAM INDUSTRIAL stands out with a verified 100% on-time delivery rate and sub-one-hour response time, indicating strong operational discipline despite limited reorder data. Changzhou Naite demonstrates high customer retention (40% reorder rate) and broad customization capacity, supported by diversified manufacturing services. DIMUD TECHNOLOGY and SkyReach offer ultra-low MOQs (as low as 1 piece), ideal for R&D and prototype phases, though lower reorder rates suggest potential gaps in long-term satisfaction or consistency. Bozhan Precision provides access to forging and casting capabilities, expanding scope for integrated component solutions, though performance metrics are incomplete.

FAQs

How to verify CNC machining supplier capability?

Request machine lists, including spindle types, axis configurations, and work envelope dimensions. Validate process controls through sample inspection reports (e.g., CMM, roughness testing). Confirm material traceability via mill certificates and conduct video audits to assess shop floor organization and QC workflows.

What is the typical lead time for custom CNC parts?

Prototype lead times range from 7–14 days. Production batches typically require 15–30 days post-approval, depending on complexity and order volume. Expedited services may reduce timelines by 30–50% with premium pricing.

Do suppliers support international shipping and customs clearance?

Yes, most suppliers manage global logistics via air or sea freight under FOB, CIF, or DDP terms. Ensure Incoterms are clearly defined and confirm experience shipping to your destination country, particularly regarding import regulations for machined metal components.

Are free samples available for CNC machined components?

Sample policies vary. Some suppliers offer paid samples refundable against future orders. Expect sample costs to cover 50–70% of unit production expenses, especially for exotic materials like titanium or Inconel.

What customization options are typically offered?

Suppliers commonly support customization in material grade, geometric dimensions, surface finish (e.g., anodizing color, Ra value), laser engraving, packaging configuration, and branding elements such as logos and labels. Advanced providers offer design collaboration and tolerance optimization.