Precision Cnc Turned Components

CN

CN

Top sponsor listing

Top sponsor listing

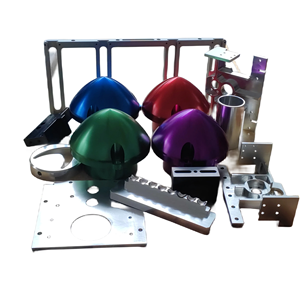

About precision cnc turned components

Where to Find Precision CNC Turned Components Suppliers?

China remains the global epicenter for precision CNC turned components manufacturing, with concentrated industrial hubs in Guangdong Province—particularly Shenzhen and Dongguan—driving innovation and scale. These regions host vertically integrated supply chains, combining advanced machining infrastructure with rapid prototyping capabilities and proximity to Tier-1 electronics, automotive, and medical device OEMs. Shenzhen’s ecosystem supports high-mix, low-to-medium volume production with tight tolerances (±0.005mm), while Dongguan specializes in high-volume runs leveraging automated CNC lathes and multi-spindle machines.

The clustering effect enables suppliers to offer reduced lead times (typically 15–25 days for custom orders) and cost efficiencies through localized material sourcing and secondary processing services such as anodizing, plating, and laser marking. Buyers benefit from co-location of design engineers, metrology labs, and logistics providers within a 30km radius, facilitating agile development cycles and just-in-time delivery models. Average production costs are 20–35% lower than equivalent Western suppliers due to optimized labor-to-automation ratios and streamlined regulatory compliance pathways.

How to Choose Precision CNC Turned Components Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality Management Systems

Verify adherence to ISO 9001 standards as a baseline for process control. For regulated industries (medical, aerospace, automotive), demand evidence of IATF 16949 or AS9100 certification. Request inspection reports including First Article Inspection (FAI), Coordinate Measuring Machine (CMM) data, and material traceability documentation. Surface finish consistency (Ra 0.8–3.2 µm typical) and geometric dimensioning & tolerance (GD&T) compliance should be validated per ANSI Y14.5 or ISO 1101.

Production Capability Assessment

Evaluate core machining capacity:

- Minimum investment in 3-axis and 5-axis CNC turning centers with live tooling

- In-house capability for milling, threading, knurling, and slotting operations

- Support for bar feeding systems enabling continuous production runs

- Secondary operations including heat treatment, passivation, and coating

Cross-reference equipment lists with on-time delivery performance (target ≥95%) and reorder rates (>25% indicates customer retention).

Customization and Scalability Verification

Confirm flexibility in handling small-batch prototypes (MOQ as low as 1 piece) and scalable ramp-up to thousands of units monthly. Assess digital workflow integration—suppliers should accept STEP, IGES, DWG, or PDF drawings and provide Design for Manufacturability (DFM) feedback within 24 hours. Prioritize partners offering color, logo, packaging, and labeling customization aligned with brand or compliance requirements.

Transaction Security Protocols

Utilize secure payment mechanisms with milestone-based releases tied to production checkpoints. Analyze response time metrics (≤4 hours is competitive) and verify dispute resolution history. Pre-shipment inspections by third parties (e.g., SGS, TÜV) are recommended for initial orders exceeding 1,000 units.

What Are the Best Precision CNC Turned Components Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility | Specializations |

|---|---|---|---|---|---|---|---|---|

| Shenzhen View Well Industry Co., Ltd. | Shenzhen, CN | Machining Services, Sheet Metal Fabrication, Casting | US $20,000+ | 100% | ≤4h | 25% | 1 piece | Multi-process integration, packaging/labeling customization |

| Shenzhen Hongxiangsheng Technology Co., Ltd. | Shenzhen, CN | Machining Services, Nuts, Bolts | US $1,000+ | 100% | ≤2h | 25% | 1 pack / 10 pieces | High-frequency fasteners, iron/aluminum turning |

| Dongguan Zhixi Precision Hardware Co., Ltd. | Dongguan, CN | Machining Services | US $1,000+ | 100% | ≤2h | 66% | 1000 units / 1 dozen | High-repeatability batch production, 5-axis support |

| Shenzhen Best Precision Products Co., Ltd. | Shenzhen, CN | Machining Services, Sheet Metal, Forging | US $10,000+ | 100% | ≤5h | 50% | 1 piece | OEM/ODM small parts, brass/knuckle machining |

| Dongguan Sanyi Precision Technology Co., ltd. | Dongguan, CN | Machining Services, Moulds, Sheet Metal | US $40,000+ | 95% | ≤3h | <15% | 1 piece | Aluminum anodizing, electroplated finishes, complex geometries |

Performance Analysis

Dongguan Zhixi stands out with a 66% reorder rate, indicating strong client satisfaction in high-volume precision turning applications. Shenzhen-based suppliers dominate responsiveness, with three achieving sub-3-hour average reply times—critical for iterative design validation. Dongguan Sanyi reports the highest online revenue (US $40,000+), reflecting robust export activity and diversified service offerings despite a lower reorder rate, suggesting potential gaps in long-term client retention. All top-tier suppliers maintain 100% on-time delivery except Sanyi (95%), which may signal capacity constraints during peak demand. Buyers requiring rapid prototyping should prioritize Shenzhen Best and View Well, both supporting single-piece MOQs with full customization options.

FAQs

How to verify precision CNC turned components supplier reliability?

Cross-check quality certifications with accredited bodies. Request factory audit reports or video tours confirming CNC machine counts, calibration logs, and QC stations. Analyze historical transaction data focusing on delivery consistency and post-sale communication.

What is the typical lead time for custom CNC turned parts?

Standard lead time ranges from 10–15 days for samples and 20–25 days for production batches. Complex multi-operation components with surface treatments may require up to 35 days. Rush services (express shipping + expedited machining) can reduce timelines by 30–50% at premium cost.

Do suppliers support international shipping and customs clearance?

Yes, established exporters manage door-to-door logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm Incoterms agreement upfront and ensure all export documentation (commercial invoice, packing list, material certificates) is provided. Most suppliers comply with RoHS and REACH directives upon request.

Are free samples available for precision CNC machined parts?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to future bulk orders. Otherwise, expect to pay 50–100% of unit cost, refundable against subsequent purchase. Sample MOQ typically starts at 1–10 pieces depending on complexity.

What materials and finishes are commonly offered?

Common materials include aluminum (6061, 7075), stainless steel (303, 304, 316), brass (C3604), and carbon steel. Engineering plastics like POM, PEEK, and nylon are also processed. Standard finishes encompass natural, sandblasted, anodized (Type II/III), zinc/nickel plating, and black oxide. Custom coatings and laser engraving are widely supported.