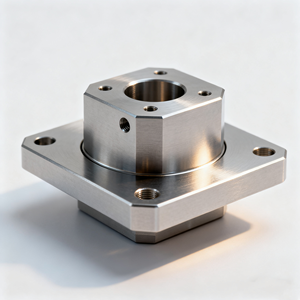

Cnc Turned Components

Top sponsor listing

Top sponsor listing

1/21

1/21

CN

CN

1/18

1/18

1/12

1/12

1/16

1/16

About cnc turned components

Where to Find CNC Turned Components Suppliers?

China remains the global epicenter for precision CNC turned components manufacturing, with concentrated supplier clusters in Guangdong Province—particularly Shenzhen and Dongguan—driving innovation and scale. These regions host vertically integrated facilities combining advanced machining centers, material sourcing networks, and rapid prototyping capabilities within compact industrial zones. Proximity to Tier-1 ports like Shekou and Yantian enables efficient export logistics, reducing transit times by 7–10 days compared to inland regions.

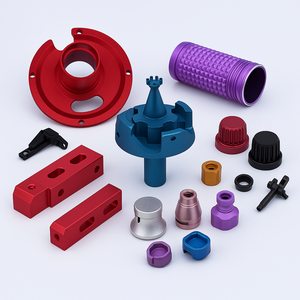

The ecosystem supports high-mix, low-to-medium volume production ideal for automotive, medical, aerospace, and industrial equipment sectors. Local suppliers typically operate mixed-model production lines featuring 4-axis and 5-axis CNC lathes, Swiss-type automatics, and multi-spindle machines, enabling tight tolerances (±0.005 mm) across diverse materials including aluminum, stainless steel, brass, titanium, and engineering plastics. Buyers benefit from agile supply chains that support batch sizes from 2 pieces to over 100,000 units annually, with average lead times ranging from 15 to 30 days depending on complexity and finishing requirements.

How to Choose CNC Turned Components Suppliers?

Effective supplier selection requires rigorous evaluation of technical capability, quality systems, and transaction reliability:

Technical & Process Capabilities

Confirm access to multi-axis turning and milling centers (4-axis/5-axis) for complex geometries. Evaluate whether the supplier offers secondary operations such as anodizing, sandblasting, laser engraving, welding, or assembly. Review design-for-manufacturability (DFM) feedback processes and compatibility with STEP/IGES/DXF file formats. Minimum acceptable tolerance should be ±0.01 mm unless specified otherwise.

Quality Assurance Standards

Prioritize suppliers with documented quality management systems. While formal ISO 9001 certification is not universally present among smaller exporters, consistent on-time delivery rates (>97%) and verifiable inspection protocols—including first-article inspection reports (FAIR), coordinate measuring machine (CMM) data, and in-process gauging—are strong proxies for process control. For regulated industries (medical, aerospace), request evidence of RoHS compliance or AS9100 certification where applicable.

Production Scalability & Responsiveness

Assess responsiveness through average reply time (≤3 hours is competitive) and reorder rate—a metric reflecting customer retention. A reorder rate exceeding 25% indicates sustained satisfaction. Cross-reference online revenue estimates (where available) with factory size indicators such as staff count and service breadth. Suppliers offering sheet metal fabrication, casting, or mold-making alongside CNC services often have broader resource pools for integrated projects.

What Are the Best CNC Turned Components Suppliers?

| Company Name | Location | Verified Type | Main Services | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| ShenZhen Selection Hardware Technology Co.,Ltd. | Shenzhen, CN | Custom Manufacturer | Machining, Casting, Sheet Metal | 100% | ≤1h | 25% | US $1.9M+ | 5-axis, anodized finish, polishing, color labeling, drawings |

| Dongguan Xingyao Precision Hardware Co., Ltd. | Dongguan, CN | - | Machining Services | 100% | ≤3h | 100% | US $7K+ | 5-axis CNC turning, aluminum alloy machining |

| Shenzhen Hongxiangsheng Technology Co., Ltd. | Shenzhen, CN | - | Machining, Nuts/Bolts, Sheet Metal | 100% | ≤1h | 25% | US $1K+ | OEM mass production, rapid prototyping |

| LML Metal Products Ltd. | Shenzhen, CN | Multispecialty Supplier | Machining, Anodizing, Molding | 100% | ≤6h | 35% | US $110K+ | Five-axis, carbon fiber, sandblasting, logo printing |

| Shenzhen Yanmi Model Co., Ltd. | Shenzhen, CN | - | Machining, Moulds, Sheet Metal | 100% | ≤3h | <15% | US $1K+ | Special-shaped turning, stainless steel parts |

Performance Analysis

All five suppliers demonstrate perfect on-time delivery records, a critical benchmark for just-in-time manufacturing environments. Dongguan Xingyao stands out with a 100% reorder rate, indicating exceptional client retention despite lower reported revenue—suggesting niche specialization or premium service execution. ShenZhen Selection Hardware leads in scalability with over US $1.9 million in estimated online sales and broad customization capacity, including 5-axis machining and full surface treatment options. LML Metal Products shows balanced performance with a 35% reorder rate and extensive material and finishing flexibility. Shenzhen-based suppliers dominate response speed, with three achieving sub-1-hour average replies, enhancing collaboration efficiency for iterative design cycles.

FAQs

What is the typical MOQ for CNC turned components?

Minimum order quantities vary widely. Several suppliers listed accept orders as low as 1–2 pieces, facilitating prototyping and small-batch production. Unit pricing decreases significantly at volumes exceeding 500 units due to setup amortization and batch processing efficiencies.

How long does it take to receive samples?

Sample lead times typically range from 7 to 15 days, depending on part complexity and requested finishes. Rapid prototyping services using existing tooling can reduce this to 5 days. Add 3–7 days for international express shipping.

Are custom materials and finishes supported?

Yes. Most suppliers accommodate customer-specified materials including 6061/7075 aluminum, SS303/316 stainless steel, brass C360, PEEK, and Delrin. Surface treatments such as hardcoat anodizing, electroplating, passivation, powder coating, and laser marking are commonly offered, often with color matching options.

Do suppliers provide design and drawing support?

Many offer free DFM analysis and assist with converting sketches or 3D models into manufacturable drawings. Suppliers like ShenZhen Selection Hardware and LML Metal Products explicitly list drawing generation, size validation, and graphic design integration as standard services.

What payment and transaction safeguards are recommended?

Use secure payment methods with buyer protection, especially for initial orders. Request partial shipments for large contracts to validate quality consistency. Retain rights to inspect goods before final disbursement, and consider third-party inspection agencies (e.g., SGS, TÜV) for orders exceeding US $10,000.