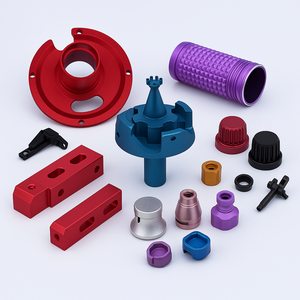

Cnc Machining Components

Top sponsor listing

Top sponsor listing

About cnc machining components

Where to Find CNC Machining Components Suppliers?

China remains the global epicenter for precision CNC machining components, with concentrated manufacturing hubs in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated industrial ecosystems that combine advanced metalworking infrastructure with streamlined logistics networks. Ningbo and Qingdao have emerged as key centers for high-mix, low-volume production, supporting rapid prototyping and custom part fabrication across aerospace, automotive, and medical device sectors.

The regional advantage lies in tightly coupled supply chains—raw material sourcing, heat treatment, surface finishing, and metrology services are typically located within 50km, reducing lead times by up to 40% compared to decentralized models. Facilities commonly operate multi-axis CNC lathes, milling centers, and wire-cut EDM systems, enabling tolerances down to ±0.005mm. Buyers benefit from scalable production capacity, with many suppliers capable of fulfilling orders ranging from single prototypes to runs exceeding 10,000 units monthly.

How to Choose CNC Machining Components Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm access to 5-axis CNC machining, turning-milling compound processing, and secondary operations such as anodizing, plating, or laser marking. For mission-critical applications, verify compliance with ISO 2768 (general tolerances), AS9100 (aerospace), or IATF 16949 (automotive). Suppliers should provide GD&T documentation and first-article inspection reports (FAIR) upon request.

Production Infrastructure Assessment

Evaluate core indicators of manufacturing maturity:

- Minimum 500m² dedicated machining floor space

- In-house design and programming teams for complex geometries

- Investment in CMM machines, optical comparators, and hardness testers

Cross-reference on-time delivery performance (target ≥94%) with response time metrics (ideally ≤2 hours) to assess operational responsiveness.

Customization & Transaction Security

Ensure suppliers support full customization—from material selection (aluminum 6061/7075, stainless steel 303/316, brass, titanium) to packaging and labeling. Prioritize partners offering digital proofing, 3D modeling, and revision-controlled drawing management. Use secure payment mechanisms with milestone-based releases tied to production updates and pre-shipment inspections.

What Are the Best CNC Machining Components Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Key Capabilities |

|---|---|---|---|---|---|---|

| Ningbo Baozhen Machinery Co., Ltd. | Machining Services (1,108) | 100% | ≤2h | 24% | US $70,000+ | Full customization, color film coating, wire cutting, logo engraving |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Machining Services (872) | 100% | ≤2h | - | US $10,000+ | 5-axis CNC milling, mass production, sheet metal integration |

| FENG CHENG MACHINERY INDUSTRIAL CO., LTD. | Machining Services (537) | 100% | ≤3h | 25% | US $1,000+ | ISO 9001-certified, stainless steel specialists, forging integration |

| SHIVAY ENTERPRISE | Machining Services (644) | 94% | ≤1h | - | US $8,000+ | High-precision turning/milling, fast quoting, small-batch expertise |

| 24K Investment (Qingdao) Co., Ltd. | Machining Services (166) | 94% | ≤2h | 20% | US $10,000+ | 5-axis aluminum machining, volume production per meter/piece |

Performance Analysis

Top-tier suppliers like Ningbo Baozhen and JINKE VIET NAM demonstrate consistent delivery performance (100%) and extensive service portfolios, indicating robust production planning and client retention. FENG CHENG stands out with a 25% reorder rate and ISO certification, signaling quality consistency in industrial-grade stainless steel components. SHIVAY ENTERPRISE leads in responsiveness (≤1h), making it suitable for urgent RFQs and iterative design cycles. While some suppliers report lower online revenue, this often reflects niche positioning rather than capability gaps—particularly for firms specializing in high-accuracy, low-volume machining.

FAQs

What is the typical MOQ for CNC machining components?

Most suppliers offer MOQs starting at 1 piece for prototypes and small batches. Volume pricing typically applies at 100–500 units depending on complexity. Some suppliers quote per unit length (e.g., centimeters of machined bar stock).

What materials are commonly used in CNC machining?

Aluminum alloys (6061, 7075), stainless steels (303, 304, 316), carbon steel, brass, copper, titanium, and engineering plastics (POM, PEEK) are standard. Material certification and traceability should be available upon request.

How long does production take?

Lead times range from 7–15 days for prototype batches and 15–30 days for larger production runs, depending on part complexity, finishing requirements, and order volume. Express services may reduce timelines by 30–50% with expedited fees.

Can suppliers handle full turnkey projects?

Yes, leading suppliers manage end-to-end processes including design validation, DFM analysis, CNC programming, assembly, and packaging. Many offer kitting, labeling, and drop-shipping services for OEM clients.

Are samples available before mass production?

Sample production is standard practice. Most suppliers provide functional prototypes for design verification, with costs often credited toward bulk orders. Expect 5–10 days for sample machining and testing.