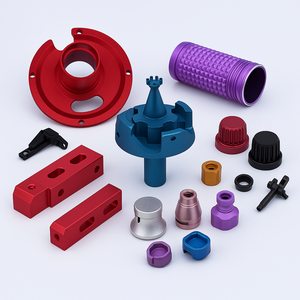

Cnc Machining Part

1/17

1/17

1/24

1/24

1/36

1/36

1/39

1/39

1/19

1/19

1/21

1/21

1/14

1/14

1/15

1/15

1/32

1/32

About cnc machining part

Where to Find CNC Machining Part Suppliers?

China remains the global epicenter for precision CNC machining part production, with concentrated manufacturing hubs in Guangdong, Sichuan, and Fujian provinces. Shenzhen and Foshan in Guangdong province lead in high-mix, low-volume custom fabrication, supported by advanced 5-axis CNC infrastructure and rapid prototyping capabilities. Chengdu-based manufacturers specialize in medium-to-high volume runs for industrial automation and energy sectors, leveraging lower operational costs and vertically integrated supply chains.

These clusters offer mature ecosystems where material sourcing, secondary processing (e.g., anodizing, heat treatment), and logistics converge within compact geographic zones. Buyers benefit from reduced lead times—typically 15–25 days for custom orders—and cost advantages driven by localized tooling and labor efficiency. The presence of multispecialty suppliers enables seamless integration of casting, sheet metal fabrication, and CNC turning/milling under one roof, enhancing project scalability and process control.

How to Choose CNC Machining Part Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Confirm adherence to ISO 9001 or equivalent quality management systems as a baseline. For regulated industries (medical, aerospace, automotive), request evidence of AS9100, IATF 16949, or RoHS compliance. Validate dimensional accuracy through provided inspection reports (e.g., CMM reports) and tolerance documentation, typically ranging from ±0.005 mm to ±0.05 mm depending on complexity.

Production Capability Assessment

Evaluate key operational metrics:

- Minimum investment in multi-axis CNC centers (3-, 4-, and 5-axis) for complex geometries

- In-house capabilities covering milling, turning, wire EDM, and surface finishing (anodizing, plating, powder coating)

- Material expertise across aluminum alloys (6061, 7075), stainless steel (303, 304, 316), brass, titanium, and engineering plastics (POM, PEEK, ABS)

Cross-reference online revenue indicators and reorder rates as proxies for market acceptance and service consistency. Prioritize suppliers with response times under 2 hours and on-time delivery performance exceeding 85%.

Customization & Transaction Safeguards

Ensure clear protocols for handling custom drawings, IP protection, and revision control. Favor suppliers offering digital proofing (e.g., 3D renderings, sample prototypes) before full production. Utilize secure payment mechanisms that align financial release with verified delivery milestones. Request physical or virtual factory audits to confirm equipment capacity and quality control workflows prior to large-scale engagement.

What Are the Best CNC Machining Part Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Junchenwen Metal Accessories Co., Ltd. | Guangdong, CN | Machining Services, Casting, Sheet Metal | US $30,000+ | 99% | 20% | ≤1h | 1–2 pcs | $30 – $4.59 |

| Foshan Mogel Hardware And Plastic Co., Ltd. | Guangdong, CN | Custom engraving, polishing, heat treatment | US $200,000+ | 86% | 56% | ≤1h | 1 pc | $0.10 – $10 |

| Chengdu Dongsheng Machinery Manufacturing Co., Ltd. | Sichuan, CN | CNC turning, milling, labeling, color coding | US $50,000+ | 80% | 39% | ≤2h | 1–10 pcs | $0.30 – $0.68 |

| Shenzhen Honscn Precision Parts Co.,Ltd | Guangdong, CN | 4-/5-axis CNC, laser cutting, sheet metal | US $140,000+ | 87% | 29% | ≤2h | 10–100 pcs | $0.23 – $2.68 |

| DIMUD TECHNOLOGY CO., LIMITED | Fujian, CN | Machining, molds, plastic/metal components | US $10,000+ | 66% | <15% | ≤1h | 1 pc | $0.10 – $1.00 |

Performance Analysis

Foshan Mogel stands out with the highest reorder rate (56%) and extensive customization options, indicating strong customer satisfaction in niche finishing processes. Shenzhen Junchenwen leads in reliability with a 99% on-time delivery rate, ideal for time-sensitive procurement. Shenzhen Honscn offers competitive pricing at scale (MOQ 10+ units), suitable for mid-volume production. DIMUD Technology provides the lowest entry-level pricing but shows below-average delivery performance, suggesting caution for mission-critical applications. Chengdu Dongsheng balances affordability and moderate volume flexibility, serving well-defined industrial use cases.

FAQs

How to verify CNC machining part supplier reliability?

Review documented quality systems (ISO certification), inspect sample reports (CMM, material test certificates), and validate transaction history via verifiable revenue tiers and buyer feedback. Conduct video audits to assess shop floor organization, machine calibration, and QC checkpoints.

What is the typical MOQ and lead time?

Standard MOQ ranges from 1 to 100 pieces, with most suppliers accommodating single-piece sampling. Lead times average 10–15 days for prototypes and 15–25 days for production batches, depending on complexity and finishing requirements.

Can suppliers handle complex material specifications?

Yes, leading suppliers support diverse materials including hardened steels, non-ferrous alloys, and high-performance polymers. Confirm material traceability and in-house testing for critical applications requiring mechanical or corrosion resistance validation.

Do suppliers provide free samples?

Sample policies vary: some waive fees for future bulk commitments, while others charge partial production costs. Expect $0.10–$30 per sample unit depending on geometry and material. Reimbursement upon order placement is common for qualified buyers.

How to initiate a customization request?

Submit detailed technical packages including 2D/3D CAD files, GD&T specifications, surface finish requirements, and intended application. Top-tier suppliers respond with feasibility analysis, DFM feedback, and quotation within 24–48 hours.