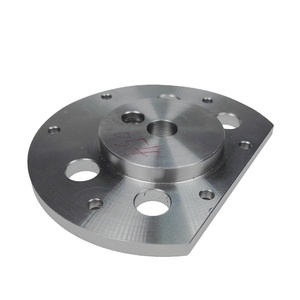

Cnc Components

Top sponsor listing

Top sponsor listing

1/23

1/23

1/19

1/19

CN

CN

1/18

1/18

1/36

1/36

1/24

1/24

1/24

1/24

1/16

1/16

1/29

1/29

About cnc components

Where to Find CNC Components Suppliers?

China remains the global epicenter for precision CNC components manufacturing, with key industrial clusters concentrated in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated supply chains combining raw material processing, advanced machining, and surface treatment services within tightly coordinated ecosystems. Shenzhen and Dongguan in Guangdong specialize in high-mix, low-volume production for aerospace, medical, and automation sectors, leveraging proximity to Tier-1 electronics manufacturers. Changzhou and Suzhou in Jiangsu focus on heavy industrial applications, supported by robust tooling infrastructure and a skilled labor pool trained in multi-axis machining.

The concentration of technical expertise and supporting industries enables rapid prototyping (typically 5–7 days) and scalable batch production. Suppliers benefit from localized access to aluminum, stainless steel, brass, and engineering plastics, reducing material lead times by 20–30%. Buyers gain flexibility in order volume, with many suppliers accommodating MOQs as low as 1 piece for prototypes and scaling to tens of thousands for serial production. Average delivery cycles range from 15 to 25 days depending on complexity and finishing requirements.

How to Choose CNC Components Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance Standards

Confirm adherence to internationally recognized quality management systems such as ISO 9001. For regulated industries (medical, automotive, aerospace), demand evidence of IATF 16949 or AS9100 certification. Review inspection protocols including first-article inspection (FAI), in-process checks, and final dimensional reporting using CMM or optical measurement systems.

Manufacturing Capability Assessment

Evaluate core competencies through verifiable indicators:

- Availability of 3-, 4-, and 5-axis CNC machining centers for complex geometries

- In-house capabilities in turning, milling, grinding, drilling, and EDM

- Integration of secondary processes: anodizing, plating, powder coating, laser engraving, heat treatment

- Digital design support: CAD/CAM compatibility, DFM feedback, GD&T analysis

Cross-reference equipment lists with on-time delivery performance (target ≥98%) and reorder rates (>20% indicates customer satisfaction).

Customization & Compliance Verification

Ensure suppliers can accommodate material specifications (e.g., 6061-T6 aluminum, 303/304/316 stainless steel, free-cutting brass), tight tolerances (±0.005 mm typical), and surface finishes (Ra ≤1.6 μm). Validate compliance with RoHS, REACH, and DFARS where applicable. Request sample parts or facility videos to confirm process control and traceability.

Procurement Safeguards

Utilize secure payment methods with milestone-based releases tied to production stages. Prioritize suppliers with documented dispute resolution mechanisms and transparent communication logs. Conduct pre-shipment inspections via third-party agencies for orders exceeding US$10,000. Prototype validation is critical—benchmark against drawing specifications before full-scale production.

What Are the Best CNC Components Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Changzhou Naite Metal Technology Co., Ltd. | Machining Services, Casting Services, Sheet Metal Fabrication | 93% | 25% | ≤1h | US $30,000+ | Color, material, size, logo, packaging, label, graphic |

| SkyReach Intelligent MFG Limited | CNC Machining, High-Precision Components | 87% | 15% | ≤3h | US $30,000+ | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Junchenwen Metal Accessories Co., Ltd. | Machining Services, Casting, Sheet Metal | 99% | 22% | ≤2h | US $40,000+ | Not specified |

| Dongguan Beigain Hardware Electronic Technology Co., Ltd. | Precision CNC Machined Parts, Anodized Aluminum Components | 98% | 54% | ≤4h | US $490,000+ | Plating, color, precision, packaging, label, hardness, material, size, drawings, design, extrusion, logo, graphic |

| FENG CHENG MACHINERY INDUSTRIAL CO., LTD. | Automotive Components, Stainless Steel Parts, Measurement Equipment | 100% | 16% | ≤3h | US $1,000+ | Not specified |

Performance Analysis

Dongguan Beigain stands out with the highest online revenue (US$490,000+) and a 54% reorder rate, indicating strong customer retention and consistent output quality. Its extensive customization options—including plating, hardness control, and extrusion design—make it suitable for clients requiring tailored engineering solutions. Changzhou Naite and Shenzhen Junchenwen demonstrate superior reliability with on-time delivery rates of 93% and 99%, respectively, ideal for time-sensitive production runs. FENG CHENG achieves perfect on-time performance (100%), though its lower reorder rate suggests room for improvement in post-sale engagement. SkyReach offers fast prototyping but lags in delivery consistency compared to peers.

FAQs

How to verify CNC components supplier reliability?

Validate certifications through official registries and request audit trails covering incoming material inspection, process controls, and final testing. Analyze transaction history for response speed, order fulfillment accuracy, and dispute resolution transparency. Request references or third-party inspection reports for high-value contracts.

What is the typical sampling timeline for CNC parts?

Standard samples are produced within 5–7 days after design approval. Complex components involving multi-step operations or special treatments may require 10–14 days. Air freight adds 5–7 days for international delivery. Some suppliers offer expedited 3-day sampling for urgent requests at a premium.

Can suppliers handle global shipping?

Yes, most established manufacturers manage international logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm Incoterms, export documentation, and import compliance requirements (e.g., customs codes, material declarations) during order confirmation. Sea freight is cost-effective for bulk shipments exceeding 500 kg.

Do CNC component suppliers provide free samples?

Free samples are uncommon for custom parts due to setup costs. However, some suppliers deduct sample fees from subsequent production orders above a defined threshold (e.g., 100 units). Standard catalog items may be provided free of charge to qualified buyers.

How to initiate customization requests?

Submit detailed technical packages including 2D drawings with tolerances, 3D models (STEP/IGES), material specifications, surface finish requirements, and quantity projections. Reputable suppliers will return DFM feedback within 24–48 hours and quote turnaround times based on current capacity.