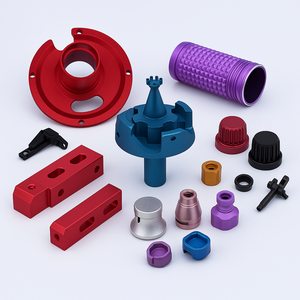

Cnc Machined Components

Top sponsor listing

Top sponsor listing

CN

CN

1/18

1/18

About cnc machined components

Where to Find CNC Machined Components Suppliers?

China and Taiwan remain central hubs for precision CNC machining, with concentrated supplier clusters in Zhejiang, Jiangsu, and Northern Vietnam offering scalable manufacturing ecosystems. These regions host vertically integrated facilities combining CNC milling, turning, wire-cut EDM, and secondary processes like anodizing and laser engraving—enabling end-to-end production under one roof. Proximity to raw material suppliers and port infrastructure reduces logistics overhead, supporting faster turnaround times and cost efficiency.

The industrial zones benefit from mature supply chains for aluminum (6061, 7075), stainless steel (303, 304, 316), brass, and titanium alloys, allowing rapid prototyping and batch production. Suppliers in Ningbo and Dongguan typically offer lead times of 10–20 days for custom orders, with express services available for urgent prototypes. Buyers gain access to flexible MOQs—from single-piece sampling to high-volume runs exceeding 10,000 units—supported by digital quoting systems and real-time engineering feedback.

How to Choose CNC Machined Components Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Process Compliance

Verify capability in multi-axis machining (3-axis, 4-axis, and 5-axis) and support for tight tolerances (±0.005 mm). While ISO 9001 certification is not explicitly listed in all cases, prioritize suppliers demonstrating documented quality control procedures. For export-bound components, ensure compliance with regional standards such as RoHS or REACH where applicable.

Production Capacity Assessment

Evaluate key indicators of scalability and reliability:

- In-house machining centers equipped with CNC lathes, milling machines, and wire-cutting equipment

- Design and engineering support for DFM (Design for Manufacturability) optimization

- Secondary processing capabilities including surface treatments (anodizing, plating, powder coating), labeling, and packaging customization

Cross-reference on-time delivery performance—suppliers reporting 100% fulfillment rates indicate robust scheduling and quality assurance protocols.

Procurement Risk Mitigation

Leverage incremental engagement strategies: start with sample orders to validate dimensional accuracy, surface finish, and communication responsiveness. Use detailed drawings (in STEP, DWG, or PDF format) to minimize interpretation errors. Confirm packaging methods and labeling requirements early to avoid downstream logistics issues. Response time ≤2 hours suggests dedicated sales-engineering teams capable of handling complex technical queries efficiently.

What Are the Best CNC Machined Components Suppliers?

| Company Name | Location | Verified Type | Main Services | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Ningbo Baozhen Machinery Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Machining Services | 100% | ≤2h | 20% | US $70,000+ | Color, material, size, drawings, logo, packaging, wire cutting |

| SkyReach Intelligent MFG Limited | Guangdong, CN | Custom Manufacturer | Machining Services | 76% | ≤3h | 15% | US $30,000+ | Color, material, size, logo, packaging, graphic |

| FENG CHENG MACHINERY INDUSTRIAL CO., LTD. | Taiwan, CN | Not Specified | Machining, Forging, Casting, Bicycle Pedals, Pneumatic Tools | 100% | ≤2h | 16% | US $1,000+ | Limited data; OEM metal parts, high-accuracy machining |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Vietnam | Not Specified | Machining, Sheet Metal Fabrication, Moulds, Casting | 100% | ≤2h | - | US $10,000+ | Material, size, design, logo, color film treatment |

| DUC HOP MANUFACTURING & TRADING CO., LTD | Vietnam | Not Specified | Machining, Sheet Metal, Cutting Tools | - | ≤5h | - | - | Standard milling/turning services; limited customization visibility |

Performance Analysis

Suppliers like Ningbo Baozhen and FENG CHENG demonstrate consistent on-time delivery (100%), indicating strong production planning and quality control systems. With response times ≤2 hours and reorder rates up to 20%, these manufacturers are well-suited for repeat orders and long-term partnerships. SkyReach offers competitive pricing ($0.50–3.89/unit) and fast sampling but shows lower delivery reliability (76%), suggesting potential bottlenecks during peak demand.

Vietnamese-based JINKE provides diversified capabilities beyond CNC machining, including sheet metal and moulds, positioning it as a hybrid production partner. However, absence of reorder rate data limits insight into customer retention. DUC HOP lacks verifiable performance metrics, increasing procurement risk for mission-critical applications. Buyers should prioritize suppliers with transparent transaction histories, engineering collaboration, and proven export experience.

FAQs

How to verify CNC machined components supplier reliability?

Request evidence of process controls, inspection reports (e.g., CMM reports), and material certifications. Conduct virtual audits via factory videos or live video calls to assess machinery conditions and workflow organization. Prioritize suppliers with documented quality management practices and responsive technical teams.

What is the typical MOQ and pricing range?

MOQ varies from 1 piece (prototypes) to 1,000+ pieces for bulk production. Unit prices range from $0.10 to $30 depending on complexity, material, and finishing requirements. Low-volume orders often include setup surcharges, while larger batches achieve economies of scale.

Can suppliers handle full customization?

Yes, most suppliers support full customization—including non-standard materials, complex geometries, and branded packaging. Provide detailed CAD models and specifications for accurate quoting. Some offer DFM feedback within 24–48 hours to optimize manufacturability.

What are standard lead times?

Prototype lead times average 7–10 days. Production orders typically require 15–25 days, depending on order size and post-processing needs. Expedited services may reduce timelines by 30–50% at additional cost.

Do suppliers provide samples?

Most suppliers offer samples, often at reduced or waived cost if followed by full production orders. Sample fees may apply for highly complex or material-intensive parts, typically refundable upon order confirmation.