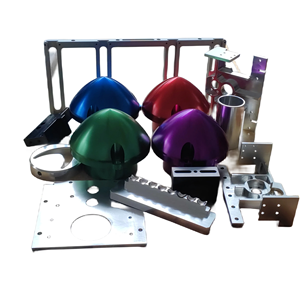

Precision Machined Components

Top sponsor listing

Top sponsor listing

About precision machined components

Where to Find Precision Machined Components Suppliers?

Asia dominates the global supply of precision machined components, with key manufacturing clusters in China and Vietnam offering scalable production ecosystems. Chinese suppliers, particularly in Guangdong and Zhejiang provinces, operate advanced CNC machining centers supported by vertically integrated fabrication services—including sheet metal work, casting, and mold-making—enabling end-to-end component manufacturing. These regions benefit from mature industrial networks where material sourcing, heat treatment, surface finishing, and quality inspection are localized within 50km radii, reducing lead times by up to 30% compared to decentralized Western operations.

Vietnam-based manufacturers like PHUC HAI COMPANY are emerging as competitive alternatives, leveraging lower labor costs and increasing technical investment to serve North American and EU markets. While production volumes remain smaller than in China, Vietnamese facilities report growing capabilities in high-tolerance CNC milling and turning, especially for stainless steel and brass components used in automotive and electric mobility applications. Buyers gain access to cost-efficient production with MOQs typically starting at 1,000 pieces, though micro-lots of 100 units are available from select Chinese suppliers.

How to Choose Precision Machined Components Suppliers?

Effective supplier selection requires verification across three core dimensions:

Technical Capability Validation

Confirm availability of multi-axis CNC machining (including 5-axis systems) for complex geometries and tight tolerances (±0.005mm). Prioritize suppliers listing in-house capabilities across turning, milling, Swiss-type machining, and wire cutting. For regulated industries, ensure compliance with ISO 9001 standards; CE or RoHS may be required for European exports. Request dimensional reports, first-article inspections (FAI), and process capability (Cp/Cpk) data for critical features.

Production & Customization Capacity

Evaluate scope through documented offerings:

- Material expertise: aluminum, stainless steel, titanium, brass, plastics

- Customization depth: logo engraving, color coding, packaging labeling, special coatings

- Drawing compatibility: support for STEP, DWG, IGES, PDF formats with GD&T annotation

- Secondary operations: anodizing, plating, passivation, sandblasting

Cross-reference stated capabilities with product listings showing actual manufactured parts, such as shafts, fixtures, and mechanical assemblies.

Transaction Reliability Metrics

Analyze performance indicators where available:

- On-time delivery rate ≥97% indicates reliable logistics management

- Reorder rate >20% reflects customer satisfaction and consistent quality

- Average response time ≤2 hours enables rapid iteration during design validation

- Online transaction volume (e.g., US $70,000+) suggests established export experience

Require sample prototypes before full-scale orders. Benchmark dimensional accuracy against ASME Y14.5 standards and verify surface finish using profilometer readings.

What Are the Best Precision Machined Components Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Huizhou Jiyan Hardware Co., Ltd. | Guangdong, CN | Machining Services, Shafts, Sheet Metal Fabrication, Casting, Moulds | Material, size, drawings, logo, packaging, label, graphic, dimensions | 100% | ≤1h | 21% | US $40,000+ | 1 piece |

| SkyReach Intelligent MFG Limited | Guangdong, CN | Not specified | Color, material, size, logo, packaging, label, graphic | 87% | ≤3h | 15% | US $30,000+ | 1 piece |

| Ald Precision Manufacturing Co., Ltd. | Guangdong, CN | Casting, Machining, Sheet Metal, Moulds | Limited customization data | 100% | ≤1h | - | US $1,000+ | 1 set |

| PHUC HAI COMPANY | Vietnam | Machining Services, Casting, CNC Lathe, Ceramics, Plastic Parts, Shafts | Limited customization data | 100% | ≤7h | - | US $4,000+ | 1,000 pieces |

| Ningbo Baozhen Machinery Co., Ltd. | Zhejiang, CN | Not specified | Color, metal, film treatment, packaging, material, size, drawings, wire cutting, design, logo, graphic | 100% | ≤2h | 24% | US $70,000+ | 100 pieces |

Performance Analysis

Huizhou Jiyan and Ningbo Baozhen stand out for high responsiveness (≤1h and ≤2h, respectively), perfect on-time delivery records, and robust customization options backed by substantial online transaction volumes. Ningbo Baozhen’s 24% reorder rate—the highest among listed suppliers—indicates strong post-delivery satisfaction, likely driven by consistent quality in stainless steel and titanium components. Ald Precision and PHUC HAI also achieve 100% on-time delivery but offer limited evidence of customization breadth or repeat business metrics. SkyReach, while providing low per-unit pricing ($0.10–$3.89), has a lower on-time delivery rate (87%) and slower response time, suggesting potential scalability constraints. Buyers requiring rapid prototyping should prioritize suppliers offering 1-piece MOQs and sub-2-hour communication cycles.

FAQs

How to verify precision machined components supplier reliability?

Validate ISO 9001 certification status through accredited registrars. Request factory audit reports or video tours confirming CNC machine counts, calibration logs, and QC inspection stations. Analyze transaction history for consistency in order fulfillment and dispute resolution outcomes.

What is the typical sampling timeline?

Standard prototype production takes 7–14 days for simple geometries. Complex parts requiring 5-axis programming or secondary finishes may require 20–25 days. Air shipping adds 5–10 days for international delivery.

Can suppliers handle small-batch or custom orders?

Yes, many suppliers accept MOQs as low as 100 pieces (e.g., Ningbo Baozhen) or even single units for initial testing. Customization includes material selection, geometric modifications, branding, and packaging tailored to OEM requirements.

Do manufacturers provide free samples?

Free samples are uncommon for precision-machined parts due to setup costs. Most suppliers charge partial fees covering material and programming, which may be credited toward future bulk orders exceeding 1,000 units.

How to initiate a customization request?

Submit detailed technical packages including 2D/3D CAD files, material specifications, tolerance callouts, surface finish requirements, and any special packaging instructions. Reputable suppliers respond within 24 hours with manufacturability feedback and quotation breakdowns.