High Precision Machining Components

Top sponsor listing

Top sponsor listing

About high precision machining components

Where to Find High Precision Machining Components Suppliers?

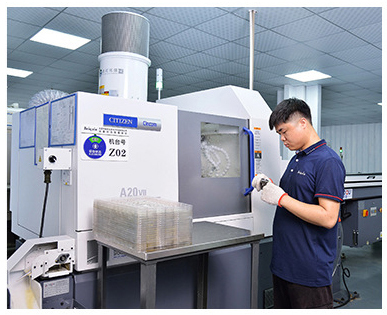

China remains the global epicenter for high precision machining components, with leading suppliers concentrated in Guangdong and Jiangsu provinces. Shenzhen and Dongguan in Guangdong host advanced manufacturing clusters specializing in CNC machining, offering integrated ecosystems that combine design engineering, rapid prototyping, and mass production. These regions benefit from proximity to Tier-1 automotive, medical device, and electronics OEMs, enabling tight supply chain coordination and fast iteration cycles.

The industrial infrastructure supports both low-volume custom batches and high-volume production runs, with many facilities operating multi-axis CNC lathes, 5-axis milling centers, and automated inspection systems. Suppliers leverage localized access to raw materials—including aluminum alloys (6061, 7075), stainless steel (303, 316), titanium, and engineering plastics like POM-C and acrylic—reducing material lead times by up to 40%. Average delivery windows range from 15–30 days depending on complexity, with express processing available for prototypes within 5–7 days.

How to Choose High Precision Machining Components Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Quality Systems

Verify ISO 9001 certification as a baseline for quality management. For regulated industries (medical, aerospace, automotive), confirm adherence to AS9100 or IATF 16949 standards. Demand documented inspection protocols, including CMM reports, surface roughness testing, and GD&T compliance verification. Suppliers should support 2D/3D drawing formats (DWG, DXF, STEP, IGES) and offer design optimization feedback prior to production.

Production Infrastructure Assessment

Evaluate key indicators of scalability and precision:

- In-house CNC machining capacity (minimum 20+ machines recommended for volume stability)

- Surface treatment capabilities: anodizing, plating (chrome, nickel), sandblasting, passivation

- Tolerance capability down to ±0.005 mm for critical features

- Integration of QA processes at each stage (pre-machining, in-process, final inspection)

Cross-reference claimed capabilities with response time performance and on-time delivery rates—ideally exceeding 95%—to assess operational reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services tied to shipment milestones. Prioritize suppliers with transparent transaction histories, including verifiable reorder rates and dispute resolution records. Prototyping is strongly advised: request functional samples to validate dimensional accuracy, finish quality, and material properties before full-scale ordering.

What Are the Best High Precision Machining Components Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Online Revenue |

|---|---|---|---|---|---|---|---|

| Shenzhen VMT Metal Product Co., Ltd. | Guangdong, CN | Machining Services (590) | 96% | ≤3h | 18% | Anodization, plating, sandblasting, turning, extrusion, assembly drawings | US $1,300,000+ |

| PHUC HAI COMPANY | Vietnam | Machining Services (190) | 100% | ≤7h | - | Limited public data | US $4,000+ |

| Ald Precision Manufacturing Co., Ltd. | Guangdong, CN | Castings (221), Machining (103) | 100% | ≤1h | - | Material, size, finish customization | US $1,000+ |

| SkyReach Intelligent MFG Limited | Guangdong, CN | Machining Services (data not listed) | 87% | ≤3h | 15% | Color, material, size, logo, packaging, graphics | US $30,000+ |

| SOZN IRONWARE PRODUCTS LIMITED | Guangdong, CN | Machining Services (171) | 100% | ≤4h | <15% | Custom turning/milling, brass/bronze components | US $600+ |

Performance Analysis

Shenzhen VMT stands out with the highest online revenue and extensive customization breadth, supporting complex finishing and design integration across over 590 machining service listings. Ald Precision and PHUC HAI achieve perfect on-time delivery records, with Ald excelling in sub-one-hour responsiveness—critical for urgent RFQs. While SkyReach offers granular customization down to labeling and packaging, its 87% on-time rate indicates potential fulfillment risks under peak load.

Suppliers based in Guangdong dominate response speed, with three achieving ≤3h average replies. Buyers requiring tight tolerances and secondary operations should prioritize vendors with documented process controls and broad post-processing options. For long-term partnerships, favor suppliers with proven reorder activity and robust machining portfolios over those focused primarily on casting or sheet metal.

FAQs

How to verify high precision machining supplier credibility?

Request copies of quality certifications (ISO 9001, RoHS) and inspect product listings for detailed specifications, tolerance callouts, and inspection reports. Analyze customer feedback focusing on consistency in part quality and communication clarity during revisions.

What is the typical MOQ and pricing structure?

MOQ varies widely: some suppliers accept single-piece orders (e.g., SkyReach), while others require 10,000 units (e.g., PHUC HAI). Unit prices range from $0.10 for simple turned parts to over $2.00 for complex, multi-operation components with special finishes.

Do suppliers support prototyping and small batches?

Yes, most offer prototype services with no minimum order, delivering sample parts within 5–10 days. Rapid iteration is supported through digital quoting and DFM analysis, especially among suppliers with strong online engagement.

Can machining components be customized with branding?

Multiple suppliers—including SkyReach and SOZN Ironware—offer logo engraving, custom packaging, and color-coded anodization. Provide vector artwork and Pantone codes for accurate reproduction.

What materials are commonly used in high precision machining?

Aluminum 6061-T6 and 7075-T6 dominate for lightweight strength; stainless steel 303/316 is preferred for corrosion resistance. Engineering plastics like POM-C (Delrin), acrylic, and nylon are used for non-conductive or wear-resistant applications.