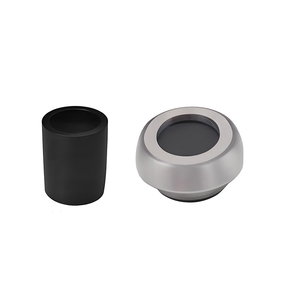

Precision Tooling Components

CN

CN

About precision tooling components

Where to Find Precision Tooling Components Suppliers?

China remains the global epicenter for precision tooling components manufacturing, with key production clusters in Guangdong, Zhejiang, and Jiangsu provinces. Shenzhen and Hangzhou host advanced CNC machining hubs specializing in high-tolerance tooling systems for automotive, aerospace, and medical equipment sectors. These regions benefit from dense ecosystems of material suppliers, metrology labs, and logistics networks, enabling rapid prototyping and scalable production.

The industrial clusters support vertically integrated operations—from raw material sourcing to final inspection—reducing lead times by 25–40% compared to decentralized supply chains. Suppliers typically operate multi-axis CNC milling, turning, grinding, and EDM processes with tolerances down to ±0.001mm. Average monthly output capacity ranges from 50,000 to over 500,000 units depending on complexity, with common materials including stainless steel, aluminum alloys, titanium, and ductile iron. This concentration allows buyers to access both standardized components and fully customized solutions under flexible MOQs.

How to Choose Precision Tooling Components Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to international quality standards such as ISO 9001. While not all suppliers list formal certifications in public data, consistent on-time delivery rates above 96% and documented inspection protocols indicate robust quality management. For regulated industries (e.g., medical or automotive), request evidence of process validation, first-article inspections, and traceable material certifications (RoHS, REACH).

Production Capabilities Assessment

Evaluate core competencies through service offerings and infrastructure indicators:

- Primary processing methods: CNC milling, turning, grinding, wire EDM, and jig boring

- In-house capabilities in machining, sheet metal fabrication, casting, and mold making

- Dedicated R&D or engineering teams for custom fixture and gauge design

- Use of coordinate measuring machines (CMM) and optical comparators for dimensional verification

Cross-reference listed product ranges with actual specialization—for instance, a supplier listing 1,400+ machining service items likely has substantial capacity and experience in serial production.

Procurement & Transaction Risk Mitigation

Prioritize suppliers with transparent communication metrics and verifiable performance history:

- Response time ≤4 hours indicates active order management

- On-time delivery rate ≥96% correlates with reliable production planning

- Reorder rates above 25% suggest customer satisfaction and product consistency

Request sample batches before large-scale orders to evaluate surface finish, dimensional accuracy, and packaging. Use third-party inspection services for batch validation when required. Confirm packaging standards and export documentation support for international shipments.

What Are the Best Precision Tooling Components Suppliers?

| Company Name | Location | Main Materials | Processing Techniques | Monthly Output Estimate | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Wish Precision Technology Co., Ltd. | Guangdong, CN | Stainless Steel, Alloy Steel | CNC Machining, Fixturing | 80,000+ units | 96% | ≤3h | US $180,000+ | 35% |

| Ald Precision Manufacturing Co., Ltd. | Zhejiang, CN | Brass, Ductile Iron, Stainless Steel | CNC Milling/Turning, Casting | 100,000+ units | 100% | ≤1h | US $1,000+ | - |

| Hangzhou Uniwise International Co., Ltd. | Zhejiang, CN | Steel, Aluminum | CNC Machining, Gear Cutting | 40,000+ units | 100% | ≤9h | US $7,000+ | <15% |

| Nanjing Precision Engineering Co., Ltd. | Jiangsu, CN | Stainless Steel, Titanium, Aluminum | CNC Machining, Sheet Metal, Casting | 200,000+ units | 96% | ≤4h | US $140,000+ | 27% |

| VARIOUS MACHINING SOLUTIONS LLP | Hebei, CN | Steel, Brass, Aluminum | CNC Milling, Turning, Jig/Fixture Fabrication | 70,000+ units | - | ≤9h | - | - |

Performance Analysis

Nanjing Precision Engineering stands out with extensive machining and fabrication listings (1,455+), indicating large-scale production capability and diversified processing expertise. Ald Precision achieves perfect on-time delivery and fastest response times, suggesting strong operational control despite limited public revenue data. Shenzhen Wish and Nanjing exhibit higher reorder rates (35%, 27%), reflecting sustained buyer confidence. VARIOUS MACHINING SOLUTIONS offers competitive pricing but lacks verifiable performance metrics, increasing procurement risk. Buyers seeking complex, low-volume tooling may favor Hangzhou Uniwise’s focus on robotics and optical instruments, while high-volume OEMs should prioritize suppliers with proven sheet metal and casting integration.

FAQs

What is the typical MOQ for precision tooling components?

MOQ varies significantly: many suppliers offer 1-piece sampling for prototypes, while bulk production runs often start at 100–500 pieces. Some quote per kilogram (e.g., ductile iron parts), allowing flexibility in unit count based on weight.

How long does it take to receive samples?

Standard sample lead time ranges from 7 to 15 days, depending on complexity and post-processing requirements (e.g., heat treatment, plating). Shipping adds 3–7 days via express carriers.

Can suppliers handle full customization?

Yes, most listed suppliers provide OEM/ODM services with CAD/CAM-based design support. Submit STEP or IGES files for quoting. In-house engineering teams can assist in optimizing designs for manufacturability and cost efficiency.

What surface finishes and coatings are available?

Common options include anodizing, electroplating, passivation, black oxide, and PVD coatings. Surface roughness typically reaches Ra 0.8–1.6 µm, with fine grinding achieving Ra 0.2 µm for critical sealing surfaces.

Are inspection reports provided with shipments?

Leading suppliers offer first-article inspection (FAI) reports and CMM-generated dimension reports upon request. For regulated industries, request full traceability documentation including material mill certificates and process flow charts.