Cnc Engraving Machine Price In Delhi

About cnc engraving machine price in delhi

Where to Find CNC Engraving Machine Suppliers?

China remains the dominant global manufacturing hub for CNC engraving machines, with key industrial clusters concentrated in Shandong and Jiangsu provinces. These regions host vertically integrated supply chains that encompass casting, precision machining, control system integration, and final assembly—enabling competitive pricing and scalable production. Shandong, in particular, is home to over 40% of China’s woodworking and metal processing machinery exporters, supported by mature logistics networks through Qingdao Port, which facilitates efficient shipment to international markets including India.

Suppliers in these zones benefit from localized access to critical components such as servo motors, spindle units, and motion guides, reducing lead times and production costs by 15–25% compared to non-specialized manufacturers. Buyers sourcing CNC engraving machines for use in Delhi gain logistical advantages due to established sea routes from eastern Chinese ports to Nhava Sheva and Mundra, with typical transit durations of 18–25 days. The concentration of technical talent and component suppliers within a 50km radius allows for rapid prototyping, customization, and after-sales support scalability.

How to Choose CNC Engraving Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional parameters:

Technical Capability Assessment

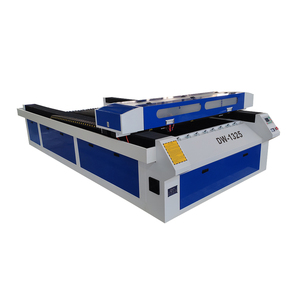

Verify machine specifications align with intended applications—wood, acrylic, metal, foam, or stone engraving. Confirm spindle speed (typically 6,000–24,000 RPM), working area (e.g., 1325 = 1300x2500mm), and control systems (e.g., RichAuto, NC Studio). Demand documentation on motor type (stepper vs. servo), tool-changing mechanisms, vacuum table functionality, and software compatibility (e.g., Type3, ArtCam).

Production and Quality Verification

Prioritize suppliers demonstrating measurable quality control metrics:

- On-time delivery rate exceeding 95%

- Response time under 4 hours for inquiry resolution

- In-house R&D teams supporting customization (e.g., dual-head configurations, oscillating knife integration)

- Evidence of standardized testing protocols for mechanical alignment and electrical safety

While ISO 9001 certification is not universally listed, consistent reorder rates above 30% indicate customer satisfaction and product reliability. For high-volume procurement, request facility videos or third-party audit reports to validate production capacity and process discipline.

Procurement Risk Mitigation

Utilize secure payment methods with milestone-based releases, especially when engaging newer suppliers without extensive transaction histories. Insist on pre-shipment inspection rights and clarify FOB/CIF terms upfront. Sample testing is strongly advised—evaluate dimensional accuracy, surface finish quality, and thermal stability of spindles before placing bulk orders.

What Are the Best CNC Engraving Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Jinan Leeder CNC Technology Co., Ltd. | Shandong, CN | $450,000+ | 100% | ≤1h | 42% | $1,999–16,500 | Yes |

| Jinan Camel CNC Machinery Co., Ltd. | Shandong, CN | $650,000+ | 96% | ≤3h | 19% | $1,880–3,980 | Yes |

| Ji'nan Yihai CNC Router Machinery Co., Ltd. | Shandong, CN | $60,000+ | 100% | ≤5h | - | $432–2,800 | Limited |

| BCAMCNC Machinery LLC | Shandong, CN | Not disclosed | Not disclosed | ≤4h | - | $1,500–8,999 | Limited |

| LUOX INC. | Shandong, CN | Not disclosed | Not disclosed | ≤5h | - | $1,000–4,900 | Limited |

Performance Analysis

Jinan Leeder stands out with the highest reorder rate (42%) and fastest average response time (≤1 hour), indicating strong post-sale performance and customer trust. The company offers a broad range of configurations, including heavy-duty models for wood carving and waterproof EVA foam engraving, with prices extending up to $16,500 for large-format routers. Its demonstrated capability in customization—including multi-axis setups, high-speed spindles, and specialized worktables—makes it suitable for buyers requiring application-specific adaptations.

Jinan Camel CNC combines competitive pricing ($1,880–$3,980) with robust technical support and an extensive feature set, including water-cooled spindles, T-slot tables, and laser alignment systems. Despite a lower reorder rate (19%), its high online revenue volume suggests strong market penetration and fulfillment consistency. The supplier actively supports OEM/ODM requests, making it a viable option for resellers or integrators.

Ji'nan Yihai presents one of the most aggressive price points at $432/set, targeting budget-conscious buyers. However, the low minimum order quantity (1 set) and absence of detailed customization tags suggest a focus on standardized, entry-level models. While cost-effective, limited technical differentiation may restrict suitability for precision or industrial-grade applications.

BCAMCNC and LUOX INC. offer mid-range pricing and emphasize volume production capabilities, particularly in 1325-format machines. LUOX INC. lists over 700 stone machinery variants, suggesting specialization in hard-material processing, whereas BCAMCNC’s portfolio spans woodworking and panel processing equipment. Both lack verified delivery and reorder metrics, increasing procurement risk without independent validation.

FAQs

What is the typical MOQ and lead time for CNC engraving machines?

Standard MOQ is 1 set, allowing small-scale buyers to test performance. Lead times range from 15–30 days depending on customization level. In-stock units may ship within 7 days. Sea freight from China to Indian ports takes 18–25 days.

Are CNC engraving machines customizable for specific materials?

Yes. Reputable suppliers modify spindle power, feed rate, dust extraction, and control software for materials like aluminum, acrylic, MDF, or rubber. Dual-head systems enable simultaneous roughing and finishing operations. Confirm compatibility with target materials before ordering.

Do suppliers provide technical training and after-sales support?

Most suppliers offer remote setup assistance via video call or remote desktop tools. Some provide on-site technician dispatch for an additional fee. Documentation typically includes operation manuals, wiring diagrams, and maintenance schedules. Long-term support varies—verify service availability prior to purchase.

What are common payment terms for international orders?

Standard terms include 30% advance payment via T/T, with balance due before shipment. Escrow services are available through certain platforms. Letters of credit (L/C) are accepted by larger suppliers for orders exceeding $50,000.

How can I verify machine specifications before purchasing?

Request detailed technical drawings, component brand lists (e.g., Syntec, Leadshine), and test-cut videos. Conduct factory audits via video tour to assess assembly line practices. Independent inspection agencies can perform pre-shipment quality checks upon request.