Cnc Router Machine Price In Delhi

About cnc router machine price in delhi

Where to Find CNC Router Machine Suppliers in Delhi?

Global manufacturing hubs in China, particularly Shandong and Jiangsu provinces, dominate the supply of industrial-grade CNC router machines sought by buyers in Delhi. These regions host vertically integrated production ecosystems where structural steel fabrication, precision motion components, and control systems are manufactured within close proximity. This clustering reduces component lead times by up to 40% and enables cost efficiencies of 20–30% compared to localized Indian assembly units.

Suppliers in Jining and Jinan specialize in woodworking and multi-material CNC systems, offering standardized 1325 (1300x2500mm) and 1530 configurations widely used in furniture, signage, and door manufacturing—key industries in Delhi’s NCR region. The integration of local gantry machining centers with in-house spindle calibration facilities allows for rapid prototyping and batch production. Buyers benefit from scalable output, with leading factories maintaining monthly production capacities exceeding 200 units across multiple product lines.

How to Choose CNC Router Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm adherence to international safety and performance benchmarks. CE marking is essential for electrical control panels and drive systems, ensuring compatibility with Indian industrial voltage standards (415V/3-phase). For high-precision applications, verify inclusion of ISO-certified linear guide rails (e.g., HIWIN or THK), ball screws, and DSP or Syntec controllers. Spindle power ratings should be documented—common ranges span 3kW to 9kW for wood and acrylic processing.

Production Capacity Verification

Assess infrastructure maturity through objective indicators:

- Minimum factory area of 3,000m² to support dedicated CNC machining, welding, and testing zones

- In-house engineering teams capable of customizing table size, Z-axis travel, vacuum hold-down systems, or ATC (Automatic Tool Changer) integration

- On-time delivery performance exceeding 90%, with real-time order tracking capabilities

Cross-reference supplier claims with verifiable metrics such as online transaction volume and reorder rates.

Procurement Risk Mitigation

Utilize secure payment mechanisms that release funds upon destination inspection. Prioritize suppliers participating in third-party assurance programs, which validate shipment authenticity and machine functionality. Conduct pre-shipment inspections to verify mechanical alignment, spindle runout (<0.01mm), and software integration (typically Mach3, NC Studio, or DSP).

What Are the Leading CNC Router Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

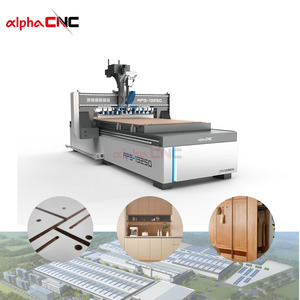

| Alpha Cnc Co., Ltd. | China | US $1,400,000+ | 100% | ≤1h | 53% | $1,500–2,500 | Yes |

| Jinan Quick-Fulltek CNC Machinery Co., Ltd. | Shandong, CN | US $30,000+ | 100% | ≤8h | <15% | $2,300–22,000 | Limited |

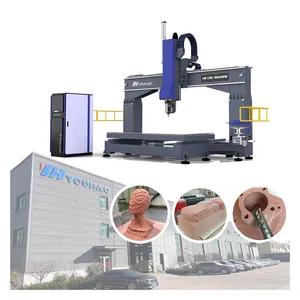

| Shandong Youhao Energy Technology Co., Ltd. | Shandong, CN | US $280,000+ | 100% | ≤1h | 25% | $2,048–54,326 | Extensive |

| Jinan Forsun Cnc Machinery Co., Ltd. | Shandong, CN | US $200,000+ | 86% | ≤3h | 23% | $500–17,500 | Yes |

| Binzhou Longfuture Machinery And Materials Co.Ltd. | Shandong, CN | US $60,000+ | 100% | ≤1h | <15% | $2,799–4,500 | Yes |

Performance Analysis

Alpha Cnc Co., Ltd. demonstrates strong buyer retention with a 53% reorder rate and sub-hour response time, indicating robust post-sales support and operational agility. In contrast, Jinan Quick-Fulltek offers higher-priced industrial models but exhibits lower customer recurrence, suggesting potential gaps in service or customization depth. Shandong Youhao stands out for engineering flexibility, supporting advanced features like 5-axis control, helical racks, and chiller-integrated spindles—critical for high-duty-cycle environments. While Jinan Forsun presents entry-level pricing, its 86% on-time delivery rate introduces scheduling risk for time-sensitive deployments. Binzhou Longfuture maintains consistent mid-range pricing with full compliance in delivery performance.

FAQs

What is the typical MOQ and lead time for CNC router machines?

Most suppliers list a minimum order quantity (MOQ) of 1 set, facilitating pilot procurement. Standard lead times range from 15 to 30 days after deposit confirmation. Complex configurations with ATC or dual-table setups may extend production to 45 days.

Can suppliers customize CNC routers for Indian workshop conditions?

Yes, leading manufacturers offer voltage adaptation (380V/50Hz), dust extraction integration, and reinforced gantry designs for continuous operation. Custom table sizes, including 1220x2440mm (standard plywood format), are routinely available.

Do suppliers provide technical training and after-sales support?

Reputable suppliers include remote setup assistance via video guidance. Some offer on-site technician deployment for an additional fee. Warranty periods typically cover 12 months for mechanical parts and 6 months for electronic components.

How does shipping impact total landed cost in Delhi?

Sea freight (FCL/LCL) from Qingdao Port to Nhava Sheva or Mundra averages 25–35 days and accounts for 8–12% of machine value. Air freight is viable only for compact 6090 models, costing 30–40% more. Import duties (10–12%) and GST (18%) must be factored into total procurement cost.

What are common customization options for CNC routers?

Buyers frequently request upgrades in spindle power (6.5kW–9kW), vacuum pod tables, automatic tool changers (ATC), DSP controllers, square linear rails, and water-cooled spindles. Software localization and multilingual interfaces are also available upon request.