Cnc Lathe Machine Fanuc Control

Top sponsor listing

Top sponsor listing

1/16

1/16

1/22

1/22

1/35

1/35

CN

CN

1/23

1/23

1/20

1/20

1/12

1/12

1/15

1/15

1/15

1/15

About cnc lathe machine fanuc control

Where to Find CNC Lathe Machine Fanuc Control Suppliers?

China remains the dominant force in the global production of CNC lathe machines equipped with Fanuc control systems, with key manufacturing clusters concentrated in Shandong and Jiangsu provinces. These regions host vertically integrated industrial ecosystems that combine precision machining capabilities, advanced automation integration, and proximity to critical component suppliers. Shandong’s Zaozhuang and Jinan zones specialize in mid-to-heavy-duty CNC turning centers, leveraging local steel and casting infrastructure to reduce material costs by 15–20%. Jiangsu’s Yangtze River Delta corridor supports high-precision machine tool manufacturing, benefiting from dense networks of electronics integrators and servo system providers essential for Fanuc-controlled equipment.

The clustering effect enables streamlined production cycles, with many suppliers operating end-to-end processes—from bed casting and guideway grinding to final assembly and CNC parameter tuning—within single facilities. This integration translates into shorter lead times (typically 30–45 days for standard configurations), scalable output for bulk orders, and enhanced flexibility for customized builds. Buyers gain access to a mature supplier base where technical expertise, responsive communication (average response time ≤2 hours), and reliable delivery performance (on-time rates exceeding 97% among top-tier vendors) are consistently demonstrated across digital sourcing platforms.

How to Choose CNC Lathe Machine Fanuc Control Suppliers?

Selecting a qualified supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Confirm that the supplier integrates genuine Fanuc controls (e.g., Series 0i-TF or 31i) and adheres to international standards such as ISO 9001 for quality management. For export markets, verify CE marking compliance to ensure conformity with EU machinery directives. Request documentation on spindle accuracy (runout ≤0.005mm), positioning repeatability (±0.003mm), and thermal compensation systems—key indicators of machining precision.

Production Capability Verification

Assess core manufacturing infrastructure through available metrics:

- Minimum factory area exceeding 5,000m² to support dedicated CNC assembly lines

- In-house machining capabilities including hard rail grinding, box-way construction, and linear guide mounting

- Integration of Fanuc control panels with spindle drives and servo motors under controlled conditions

Cross-reference declared reorder rates (target >50%) and on-time delivery records (ideal ≥98%) as proxies for operational stability and customer satisfaction.

Transaction Security & After-Sales Support

Prioritize suppliers offering structured order protection mechanisms, such as milestone-based payments and post-delivery inspection windows. Evaluate responsiveness (target ≤2-hour average reply time) and customization capacity—including options for color, labeling, logo imprinting, and packaging modifications—as indicators of service maturity. Sample validation is strongly recommended: request test cuts or dimensional reports from pre-shipment runs to verify stated accuracy and surface finish quality.

What Are the Best CNC Lathe Machine Fanuc Control Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Verification Status |

|---|---|---|---|---|---|---|---|

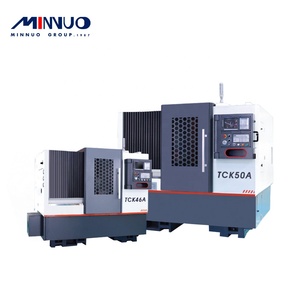

| Jiangsu Minnuo Group Co., Ltd. | Gas Generation Equipment, Machining Centre, CNC Lathe, Blowers | US $6,800,000+ | 100% | 50% | ≤2h | Color, diameter, material, size, length, accuracy, logo, packaging, label, graphic | Custom Manufacturer |

| Zaozhuang Sente Cnc Equipment Co., Ltd. | CNC Lathe, Machining Centre, CNC Milling Machines, Manual Lathe | US $50,000+ | 100% | 25% | ≤2h | Not specified | - |

| Zaozhuang Shenghuan CNC Machine Tool Co., Ltd. | CNC Lathe, Machining Centre, EDM Machines, Surface Grinding Machine | US $4,000+ | - | <15% | ≤2h | Not specified | - |

| Shandong Weste Cnc Machine Tool Co., Ltd. | Machining Centre, CNC Milling Machines, CNC Lathe, Drilling Machines | US $30,000+ | 100% | 100% | ≤3h | Not specified | - |

| Jeyew Precision Machine (Shandong) Co., Ltd. | CNC Lathe, Automatic Turning Centers, Horizontal Lathes | US $50,000+ | 100% | 50% | ≤2h | Color, size, logo, packaging, label, graphic | Custom Manufacturer |

Performance Analysis

Jiangsu Minnuo Group stands out with the highest reported online revenue (over US$6.8 million) and robust customization offerings, making it a strategic partner for buyers requiring tailored configurations at scale. Shandong Weste demonstrates exceptional customer retention, evidenced by a 100% reorder rate—indicative of consistent product performance and service reliability. While Zaozhuang Shenghuan offers competitive entry-level pricing, its low reorder rate (<15%) and lack of confirmed on-time delivery data suggest potential limitations in after-sales support or process consistency. Verified custom manufacturers like Jiangsu Minnuo and Jeyew provide added assurance for OEM/ODM projects, particularly when brand-specific design integration is required.

FAQs

How to verify CNC lathe machine Fanuc control supplier reliability?

Cross-check claimed certifications (ISO 9001, CE) with issuing bodies and request evidence of actual Fanuc control integration—not just compatibility claims. Analyze verifiable transaction history, focusing on delivery adherence, dispute resolution outcomes, and long-term reorder behavior. Video audits of assembly lines can confirm in-house production versus trading operations.

What is the typical minimum order quantity (MOQ) and lead time?

Standard MOQ is 1 unit/set across most suppliers. Lead times range from 30 to 45 days for standard models; customized configurations may extend to 60 days depending on mechanical modifications or control system programming requirements.

Can suppliers customize CNC lathes with Fanuc controls?

Yes, leading suppliers offer customization in dimensions, materials, accuracy grades, and branding elements (logo, color, packaging). Structural changes (e.g., bed length, spindle bore) require engineering validation and may affect pricing and delivery timelines.

Do these suppliers support global shipping?

All listed suppliers have established export activity. Confirm Incoterm preferences (FOB, CIF) and ensure compliance with destination-country electrical and safety regulations. Sea freight is standard for full-container shipments due to machine weight and dimensional constraints.

Is sample testing available before bulk procurement?

Sample units are typically available upon request, though not free of charge. Buyers should expect to cover partial production and handling costs. Testing should include dry runs, positioning accuracy checks, and surface finish evaluation using provided workpiece materials.