Cnc Machine Ahmedabad

About cnc machine ahmedabad

Where to Find CNC Machine Suppliers in Ahmedabad?

While Ahmedabad serves as a growing industrial hub in Western India, the majority of high-capacity CNC machine manufacturing is concentrated in China’s Shandong and Anhui provinces. These regions host vertically integrated ecosystems specializing in precision machine tools, supported by mature supply chains for cast iron, linear guides, ball screws, and CNC control systems. Shandong alone accounts for over 40% of China’s machining center output, with clustered production facilities enabling rapid component sourcing and reduced lead times.

Suppliers in these zones operate large-scale factories—many exceeding 5,000m²—with dedicated R&D departments and in-house assembly lines for milling machines, plasma cutters, and multi-axis machining centers. The proximity to steel mills and electronic component suppliers reduces material costs by 15–25% compared to decentralized manufacturing regions. Buyers benefit from scalable production capacity, with standard lead times ranging from 30 to 45 days for fully assembled units. Export-ready infrastructure ensures compliance with international packaging and shipping standards for sensitive machinery.

How to Choose CNC Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify that suppliers offer machines compliant with relevant safety and performance standards such as CE or ISO 9001. For plasma and laser cutting systems, confirm power source compatibility (e.g., 55A–100A) and motion control accuracy (±0.05mm typical). Request documentation on spindle runout, positioning repeatability, and controller integration (e.g., GSK, Fanuc, Siemens).

Production and Customization Capability

Assess core competencies through product diversity and customization scope:

- Minimum of 100+ active listings in CNC-related categories indicating market presence

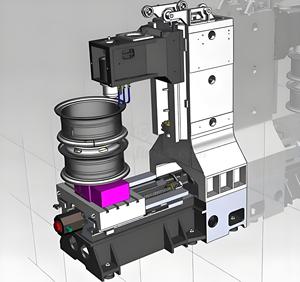

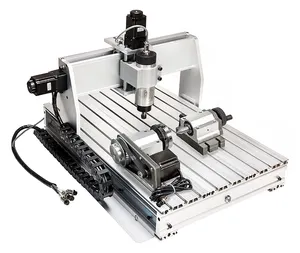

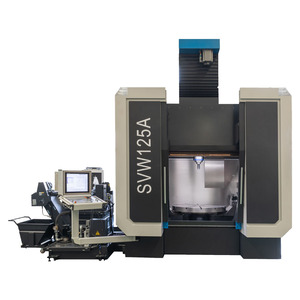

- Proven capability in key segments: vertical machining centers (VMC), CNC lathes, wood routers, or metal cutting systems

- Customization options including axis configuration (3/4/5-axis), work envelope size, and controller branding

Prioritize suppliers offering OEM/ODM services with documented design-to-delivery workflows.

Transaction Reliability Indicators

Analyze verifiable performance metrics:

- On-time delivery rate ≥98%

- Average response time ≤2 hours for inquiry resolution

- Reorder rate above 30% indicating customer retention

Cross-reference online revenue data (e.g., $950,000+ annual turnover) as a proxy for operational scale and export experience.

What Are the Leading CNC Machine Suppliers?

| Company Name | Main Products | Price Range (Min Order) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Product Listings |

|---|---|---|---|---|---|---|---|

| Jinan Hongda Cnc Equipment Co., Ltd. | CNC Lathe (710), Machining Centre (423) | $1,400–$13,000/set | 100.0% | ≤2h | 30% | US $950,000+ | 1,200+ |

| Shandong Yida CNC Machine Tool Co., Ltd. | Machining Center, VMC Series | $9,500–$34,800/set | 100.0% | ≤1h | 66% | US $130,000+ | 500+ |

| Shandong Weste Cnc Machine Tool Co., Ltd. | Machining Centre (612), CNC Milling Machines | $7,000–$28,800/unit | 100.0% | ≤3h | 100% | US $30,000+ | 800+ |

| ANHUI TOPLOONG CNC EQUIPMENT MANUFACTURING CO.,LTD. | CNC Plasma Cutters (188), Laser Cutting Machines | $458–$1,188/set | 100.0% | ≤2h | <15% | US $50,000+ | 300+ |

| Hebei Hebing Technology Co., Ltd. | Machine Tool Accessories, Vises | $1,000–$2,099/piece | 100.0% | ≤2h | 17% | US $110,000+ | 1,200+ |

Performance Analysis

Jinan Hongda stands out for diversified offerings across wood, stone, and metal processing machines, backed by strong revenue volume and broad product range. Shandong Yida demonstrates superior customer loyalty with a 66% reorder rate and sub-hour response times, ideal for buyers requiring agile communication. Shandong Weste achieves perfect reorder retention despite moderate revenue, suggesting high satisfaction among niche industrial clients. ANHUI TOPLOONG offers entry-level pricing for portable plasma systems but shows lower repeat purchase behavior, indicating potential gaps in after-sales support or long-term reliability. Hebei Hebing focuses on components rather than full machines, serving as a supplementary source for tooling and fixtures.

FAQs

How to verify CNC machine supplier reliability?

Validate certifications (ISO, CE) through issuing body databases. Request factory audit reports or video tours confirming in-house machining, welding, and testing capabilities. Evaluate quality control processes including spindle balancing, guideway scraping, and no-load run tests (typically 72 hours).

What is the typical MOQ and lead time?

Most suppliers list MOQ at 1 set/unit, facilitating pilot procurement. Standard production lead time ranges from 30 to 45 days post-deposit. Express orders may reduce timelines to 20 days at premium cost.

Can suppliers customize CNC machines?

Yes, leading manufacturers support customization of table size, axis travel, spindle power, control system (Fanuc, Siemens, Syntec), and automation interfaces. Confirm availability of 3D models and engineering drawings before order placement.

Do suppliers provide technical support and training?

Many offer remote commissioning assistance via video call. Some include basic operation manuals and PLC diagrams. Advanced support—on-site installation or staff training—may incur additional fees and require contractual inclusion.

What are common payment terms?

Standard terms include 30% T/T advance, 70% before shipment. Escrow services are available for added transaction security. Letters of Credit (L/C) are accepted by larger exporters with established banking relationships.