Cnc Machine Rajkot

1/3

1/3

1/5

1/5

1/19

1/19

1/15

1/15

1/7

1/7

CN

CN

1/12

1/12

1/21

1/21

About cnc machine rajkot

Where to Find CNC Machine Suppliers in Rajkot?

Rajkot, situated within Gujarat’s industrial corridor, has emerged as a regional hub for precision engineering and machine tool manufacturing. While not a primary production center for CNC machines itself, the city serves as a strategic procurement node connecting buyers with high-capacity manufacturers across Shandong and Henan provinces in China. These clusters—particularly Jinan and Qingdao—host vertically integrated facilities specializing in CNC routers, ATC (Automatic Tool Changer) systems, and multi-axis engraving machinery, leveraging localized steel, motor, and control system supply chains.

Manufacturers in these regions operate under economies of scale that reduce unit costs by 20–30% compared to Western producers. Integrated production lines support full-cycle manufacturing from frame fabrication to spindle integration and software calibration. Buyers sourcing via Rajkot-linked suppliers gain access to modular designs suitable for woodworking, metal engraving, stone carving, and composite material processing. Lead times for standard models typically range from 15 to 30 days, with express shipping options available for pre-assembled units.

How to Choose CNC Machine Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional parameters:

Technical Compliance

Confirm adherence to international safety and performance standards such as CE marking for electrical systems and compliance with ISO 9001 for quality management. For export markets in Europe or North America, ensure controllers (e.g., DSP, NC Studio) meet electromagnetic compatibility (EMC) requirements. Validate spindle specifications—power output (typically 3–9 kW), cooling method (air/water-cooled), and RPM range (12,000–24,000)—against intended applications like hardwood milling or aluminum trimming.

Production Capability Audits

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 3,000m² to support assembly and testing lines

- In-house capabilities in linear guide rail installation, ball screw alignment, and vacuum table fabrication

- Engineering teams offering customization for tool magazines, oscillating knife integration, or rotary axes

Cross-reference online revenue data and on-time delivery rates; prioritize suppliers with ≥96% fulfillment accuracy and response times under 2 hours.

Transaction Safeguards

Utilize secure payment frameworks that release funds upon destination inspection. Evaluate reorder rates as an indicator of post-sale satisfaction—suppliers with rates above 25% demonstrate consistent reliability. Request sample testing to validate positioning accuracy (±0.05mm typical), noise levels (<75 dB), and thermal stability during extended operation. Pre-shipment inspections should verify packaging integrity, labeling compliance, and inclusion of toolkits and user manuals.

What Are the Best CNC Machine Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

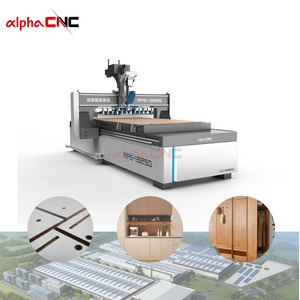

| Alpha Cnc Co., Ltd. | China | Multispecialty Supplier | US $1,400,000+ | 100% | ≤1h | 58% | Yes |

| Jinan Camel CNC Machinery Co., Ltd. | China | Multispecialty Supplier | US $660,000+ | 96% | ≤3h | 18% | Yes |

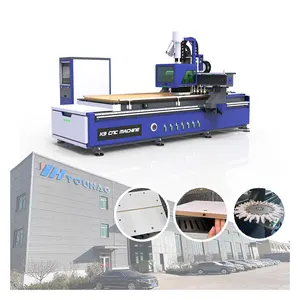

| Shandong Youhao Energy Technology Co., Ltd. | China | Custom Manufacturer | US $280,000+ | 100% | ≤1h | 25% | Yes |

| Jinan Renxi Technology Co., Ltd. | China | - | US $30,000+ | 100% | ≤2h | <15% | No |

| Blue Elephant CNC Machinery Co., Ltd. | China | - | - | - | ≤2h | - | Yes |

Performance Analysis

Alpha Cnc Co., Ltd. leads in customer retention with a 58% reorder rate and rapid ≤1-hour response time, indicating strong service consistency and technical support. Despite lower public revenue disclosure, Blue Elephant CNC offers high-end configurations including 7-axis robotic integration and large-format 1330 models priced up to $30,000, catering to specialized industrial clients. Shandong Youhao distinguishes itself as a custom manufacturer with advanced features like auto-lubrication systems, helical rack drives, and 5-axis联动 (synchronous) control, supporting complex machining workflows.

Jinan Camel CNC provides broad application flexibility, serving sectors from signage (oscillating knife cutters) to furniture (multi-spindle routers), though its 18% reorder rate suggests room for improvement in long-term client engagement. Jinan Renxi focuses on entry-level desktop models starting at $800, making it viable for small workshops but limited in after-sales scalability. Prioritize suppliers with documented customization experience and proven export logistics when procuring for regulated markets.

FAQs

How to verify CNC machine supplier reliability?

Cross-check self-reported certifications with third-party verification platforms. Request evidence of factory audits, component sourcing policies (e.g., leadshine drivers, water-cooled spindles), and after-sales service protocols. Analyze customer reviews focusing on software stability, mechanical durability, and technical troubleshooting responsiveness.

What is the average lead time for CNC machine orders?

Standard models are typically shipped within 15–25 days after order confirmation. Customized units requiring tool magazine integration, dual gantry design, or special worktable dimensions may require 30–45 days. Ready-to-ship units with pre-installed ATC systems can dispatch within 7 days.

Can suppliers accommodate OEM/ODM requests?

Yes, leading manufacturers support branding customization including logo engraving, color scheme modification, control panel labeling, and packaging design. Minimum order quantities for OEM branding typically start at 1 unit, though pricing advantages emerge at 3+ units.

Do CNC machine suppliers offer global shipping?

All listed suppliers provide worldwide delivery via sea or air freight. Confirm FOB terms and clarify responsibilities for customs clearance, import duties, and inland transportation. Sea shipping remains optimal for container loads, reducing per-unit logistics costs by up to 60% versus air express.

What customization options are commonly available?

Suppliers offer configurable options including working area (600x900 mm to 2000x3000 mm), spindle power (3–9 kW), cooling type (air/water), table type (T-slot, vacuum), axis count (3–7 axes), and automation level (manual vs. automatic tool change). Additional upgrades include dust extraction systems, laser alignment guides, and remote monitoring interfaces.