Cnc Machine In Rajkot

CN

CN

About cnc machine in rajkot

Where to Find CNC Machine Suppliers in Rajkot?

Rajkot, a growing industrial hub in Gujarat, India, has seen increasing demand for precision manufacturing equipment, particularly CNC machines. While local procurement is limited, the global supply chain—especially from China’s Shandong and Jiangsu provinces—serves as the primary source for high-performance, cost-competitive CNC machining centers. These regions host concentrated clusters of machine tool manufacturers with vertically integrated production facilities capable of delivering standard and customized CNC systems directly to Indian buyers.

Suppliers in Shandong and surrounding areas benefit from mature ecosystems that include in-house casting, CNC component machining, and final assembly lines—all within 50km radii. This integration reduces lead times by up to 30% compared to decentralized production models. With average factory sizes exceeding 5,000m² and monthly outputs ranging from 50–200 units per facility, these suppliers support both small-scale workshops and large industrial deployments. Buyers in Rajkot gain access to machines priced between $1,500 and $25,000, depending on configuration, axis count, and automation level.

How to Choose CNC Machine Suppliers for Rajkot Operations?

Selecting reliable suppliers requires a structured evaluation based on technical capability, transaction reliability, and post-sale support. The following criteria should guide procurement decisions:

Technical Specifications & Capabilities

Verify machine type alignment with intended applications: 3-axis routers for basic milling, 4–5-axis centers for complex geometries, and ATC (Automatic Tool Change) models for high-efficiency production. Spindle power (ranging from 800W to 9kW in sampled data), working size (e.g., 1325, 2040 configurations), and control systems (e.g., NC Studio, DSP) must match operational requirements. For metal cutting, ensure reinforced frames and high-torque spindles; for woodworking, prioritize vacuum tables and dust aspiration compatibility.

Production and Customization Capacity

Assess supplier flexibility through available customization options:

- Working area dimensions (from mini 6090 to industrial 2040+ formats)

- Motor type (stepper vs servo), cooling method (air/water), and spindle power

- Integration of ATC, oscillating knives, multi-head engraving, or laser positioning

- Software compatibility (CAD/CAM, DXF, G-code generation)

Leading suppliers offer modular designs allowing upgrades post-purchase. Confirm whether design modifications are supported via 3D renderings or prototype validation before full commitment.

Quality Assurance and Compliance

Although formal certifications (ISO 9001, CE) are not explicitly stated in all cases, consistent on-time delivery rates (≥96%) and verifiable online revenue (up to US $1.4M+) indicate operational maturity. Prioritize suppliers with documented quality control processes, including pre-shipment testing for accuracy, repeatability, and electrical safety. For export compliance, ensure EMC and RoHS standards are met if integrating into automated production environments.

Transaction Reliability Metrics

Use quantifiable performance indicators to assess trustworthiness:

- On-time delivery rate ≥96%

- Average response time ≤3 hours (ideally ≤1 hour)

- Reorder rate >25% as an indicator of customer satisfaction

- Minimum one-year warranty and remote technical support availability

Platforms providing verified transaction histories enable risk mitigation through trade assurance mechanisms, escrow payments, and dispute resolution frameworks.

What Are the Top CNC Machine Suppliers Serving Rajkot?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Shandong Yijin Cnc Machine Tool Co., Ltd. | Machining Centre, CNC Lathe, Manual Mills | $8,000–25,000 | 1 set | 100% | ≤1h | 50% | US $40,000+ |

| Jinan TechPro CNC Equipment Co., Ltd. | Wood Routers, 4-Axis CNC, Granite Machines | $3,200–9,000 | 1 set | 100% | ≤1h | 25% | US $580,000+ |

| BCAMCNC Machinery LLC | Wood Routers, Engraving Machines, Metal CNC | $3,999–25,400 | 1 set | Data Unavailable | ≤4h | Data Unavailable | Data Unavailable |

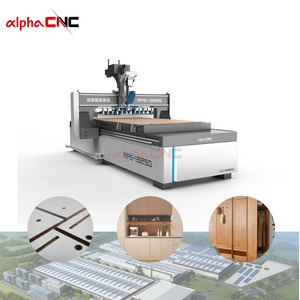

| Alpha Cnc Co., Ltd. | ATC Routers, Sheet Metal Machines, Vacuum Tables | $1,500–4,300 | 1 set | 100% | ≤1h | 58% | US $1,400,000+ |

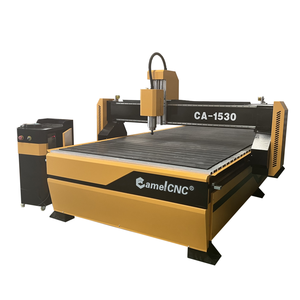

| Jinan Camel CNC Machinery Co., Ltd. | ATC CNC, Engraving Systems, Oscillating Knife | $1,880–12,500 | 1 set | 96% | ≤3h | 19% | US $650,000+ |

Performance Analysis

Alpha Cnc Co., Ltd. stands out with the highest reorder rate (58%) and lowest entry pricing ($1,500), making it ideal for SMEs and startups in Rajkot seeking budget-friendly ATC-enabled routers. Shandong Yijin offers premium vertical machining centers (VMCs) targeting precision metalworking, with prices starting at $8,000 and proven 100% on-time delivery. Jinan TechPro provides specialized solutions for stone and wood sectors, backed by extensive customization capabilities and strong export volume (US $580K+). Jinan Camel CNC demonstrates scalability across diverse applications but shows lower customer retention (19% reorder rate), suggesting potential gaps in long-term support. BCAMCNC presents wide price variability, indicating possible inconsistencies in build quality or lack of standardized output metrics.

FAQs

How to verify CNC machine supplier reliability?

Cross-check claimed delivery performance and response times against platform-verified records. Request evidence of factory audits, component sourcing practices, and after-sales service protocols. Analyze customer reviews focusing on machine calibration, software stability, and spare parts availability.

What is the typical lead time for CNC machine orders?

Standard configurations typically ship within 15–30 days after order confirmation. Custom builds with ATC, multi-axis setups, or specialized worktables may require 35–50 days. Air freight adds 5–10 days for Indian destinations; sea freight takes 25–40 days depending on port logistics.

Can suppliers accommodate OEM branding and technical modifications?

Yes, many suppliers offer OEM services including logo labeling, color configuration, control panel adjustments, and spindle upgrades. Technical changes such as increased gantry height or dual-vacuum zones require engineering validation and may affect pricing and lead time.

Do suppliers provide installation and training support?

Most suppliers offer remote setup guidance via video calls and manuals. On-site commissioning and operator training are typically available at additional cost. Confirm language proficiency (English/technical Hindi) and availability of local service partners in India before purchase.

What are common payment terms and MOQs?

Minimum order quantity is generally 1 set, enabling pilot procurement. Payment structures include T/T (30% deposit, 70% before shipment), L/C at sight, or platform-managed escrow. Buyers are advised to retain 10–15% payment until successful machine commissioning.