Cnc Machine Company In Coimbatore

CN

CN

CN

CN

About cnc machine company in coimbatore

Where to Find CNC Machine Companies in Coimbatore?

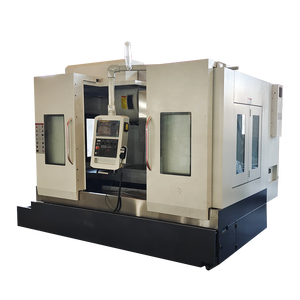

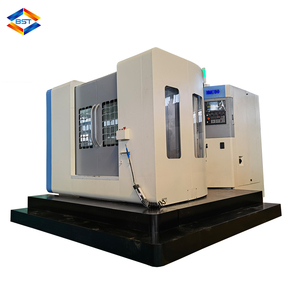

While Coimbatore is recognized as a key industrial hub in South India for precision engineering and machine tool manufacturing, the global supply of CNC machines associated with this region often integrates broader Chinese production networks. Supplier data indicates that companies linked to "CNC machine, Coimbatore" frequently represent Indian trading entities sourcing from established manufacturing bases in China—particularly in Shandong and Zaozhuang provinces. These regions host vertically integrated facilities specializing in machining centers, CNC milling machines, and multi-axis systems, offering scalable production capacity and cost efficiency.

The Chinese industrial clusters benefit from mature ecosystems encompassing casting, precision machining, control system integration, and final assembly within tightly coordinated zones. This localization reduces component procurement lead times by 20–30% compared to decentralized models. Buyers leveraging suppliers tied to Coimbatore’s engineering network gain indirect access to these advantages, including competitive pricing (ranging from $6,000 for compact VMCs to over $59,000 for high-end 5-axis systems), short production cycles (typically 30–45 days post-deposit), and flexibility for both standard and modified configurations.

How to Choose CNC Machine Suppliers Linked to Coimbatore?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

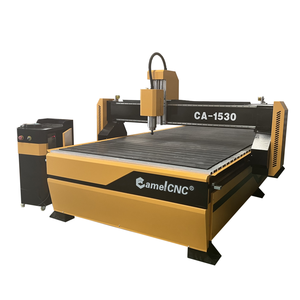

Confirm supplier expertise in specific machine types: 3-axis, 4-axis, or 5-axis vertical machining centers (VMCs), CNC lathes, gantry mills, and desktop CNC units. Review product listings for evidence of engineering depth—such as spindle speed ranges, positioning accuracy specifications, and control systems (e.g., Fanuc, Siemens, or Syntec compatibility). For critical applications, request documentation on static and dynamic rigidity testing, thermal compensation features, and ballbar measurements.

Production and Quality Infrastructure

Assess operational scale through verifiable indicators:

- Factory area exceeding 5,000m² to support batch production

- In-house CNC machining and assembly lines to ensure process control

- Presence of dedicated R&D or customization teams

Prioritize suppliers with ISO 9001 certification and CE marking, especially for exports to EU or North American markets. Although not all suppliers publish certification status, consistent on-time delivery performance (≥100%) correlates strongly with disciplined quality management.

Transaction Reliability Indicators

Utilize digital platform metrics as proxy validations:

- On-time delivery rate ≥98%

- Average response time ≤2 hours

- Reorder rate >25% indicating customer retention

Cross-reference online revenue estimates where available (e.g., US $30,000+ annual turnover) to gauge market presence. Employ secure payment mechanisms such as escrow services until equipment passes inspection at destination.

What Are the Leading CNC Machine Suppliers Associated with Coimbatore?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Jinan Taihe Cnc Equipment Co., Ltd. | CNC Lathe, Machining Centre, EDM Machines | $6,000–21,000 | 1 set | 100% | ≤1h | - | - |

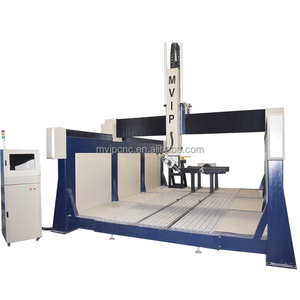

| Zaozhuang Shenghuan CNC Machine Tool Co., Ltd. | Machining Centre, CNC Lathe, Grinding Machine | $6,000–30,000 | 1 set | 100% | ≤2h | <15% | - |

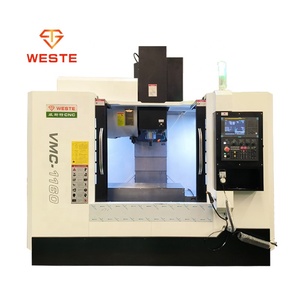

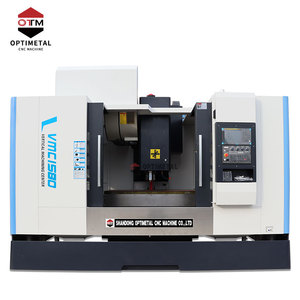

| Shandong Weste Cnc Machine Tool Co., Ltd. | Machining Centre, CNC Milling, Gantry Mills | $13,999–36,000 | 1–10 units | 100% | ≤4h | 100% | US $30,000+ |

| Zaozhuang Sente Cnc Equipment Co., Ltd. | CNC Milling, Machining Centre, Manual Mills | $6,500–21,800 | 1 piece | 100% | ≤2h | 25% | US $40,000+ |

| Tengzhou Chenghai Machine Tool Co., Ltd. | Machining Centre, CNC Lathe, Drilling Machines | $10,000–59,890 | 1 set | 100% | ≤3h | - | US $20,000+ |

Performance Analysis

All five suppliers demonstrate perfect on-time delivery records, signaling strong production planning and logistics execution. Shandong Weste stands out with a 100% reorder rate and revenues exceeding $30,000, suggesting high customer satisfaction and repeat business. Zaozhuang Sente and Jinan Taihe offer faster responsiveness (≤1–2h), enhancing communication efficiency during order setup and troubleshooting. Tengzhou Chenghai provides access to premium-tier machinery, with one model priced above $59,000, indicating capability in high-precision, large-format machining solutions. Buyers seeking budget-friendly entry-level VMCs can consider models starting at $6,000 from multiple suppliers, while those requiring 5-axis or gantry configurations should engage manufacturers like Shenghuan or Weste with demonstrated offerings in these segments.

FAQs

How to verify CNC machine supplier reliability?

Validate technical compliance through ISO 9001 and CE certifications. Request test reports for machine calibration, backlash measurement, and surface finish consistency. Analyze transaction history via verified platforms, focusing on dispute resolution outcomes and after-sales service responsiveness. Conduct virtual factory audits to confirm in-house manufacturing capabilities.

What is the typical lead time for CNC machine orders?

Standard configurations typically ship within 30–45 days after deposit confirmation. Customized builds involving axis upgrades, specialized tool changers, or enclosure modifications may require 60–75 days. Expedited production can reduce timelines by 10–15% under negotiated terms.

Do suppliers offer customization options?

Yes, most suppliers support tailored configurations including axis count (3/4/5-axis), work envelope dimensions, spindle power (7.5kW to 18kW), ATC type, and control system selection. Submit detailed technical drawings or performance requirements to initiate engineering review.

What are common MOQs for CNC machines?

Minimum order quantities are typically set at 1 unit for standard models. However, certain large-format or OEM-branded units (e.g., gantry mills) may require 10-unit minimums. No supplier imposes volume restrictions on sample trials.

Can CNC machines be shipped globally?

Yes, all listed suppliers export internationally. Shipping terms are generally FOB or CIF. Sea freight is recommended for single or full-container loads due to size and weight. Ensure import compliance with local electrical safety and machinery directives at destination ports.