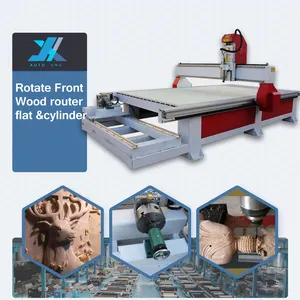

Cnc Rotary Axis Distributor

1/5

1/5

1/16

1/16

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/5

1/5

1/3

1/3

1/10

1/10

1/9

1/9

1/2

1/2

1/3

1/3

About cnc rotary axis distributor

Where to Find CNC Rotary Axis Distributor Suppliers?

China remains the global epicenter for CNC rotary axis manufacturing, with concentrated industrial clusters in Shandong and Guangdong provinces driving supply chain efficiency. Shandong, particularly Jinan and Qingdao, hosts over 70% of verified CNC machinery suppliers specializing in multi-axis systems, leveraging mature ecosystems of precision component manufacturers and automation engineers. These regions benefit from integrated logistics networks and proximity to steel and electronics suppliers, reducing material procurement lead times by up to 25% compared to offshore alternatives.

The cluster advantage extends to vertical integration—many suppliers operate full-cycle production lines encompassing casting, CNC machining, assembly, and testing within single facilities. This enables rapid prototyping, scalable batch production, and tighter quality control. Buyers gain access to flexible MOQs (as low as 1 set), customization capabilities across spindle types, control systems, and worktable configurations, and typical lead times of 20–35 days for standard models. Export-ready infrastructure supports FOB and CIF shipping terms, with sea freight being optimal for containerized orders.

How to Choose CNC Rotary Axis Distributor Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm compatibility with existing CNC systems through detailed documentation on interface protocols (e.g., NC Studio, Mach4). Verify compliance with international safety and electromagnetic standards such as CE or RoHS where applicable. Request test reports for critical components including servo motors, ball screws, and spindle cooling systems.

Production Capability Assessment

Evaluate core manufacturing competencies:

- Facility size exceeding 3,000m² indicating capacity for volume orders

- In-house engineering teams supporting CAD/CAM integration and custom configuration

- On-site testing of rotary axis runout, positioning accuracy, and thermal stability

Cross-reference performance metrics: prioritize suppliers with on-time delivery rates above 95% and response times under 4 hours.

Customization and After-Sales Support

Assess flexibility in motor type (stepper vs. servo), tool changer integration (ATC), worktable design (T-slot, vacuum), and software compatibility. Confirm availability of lifetime technical support, spare parts inventory, and remote diagnostics. Suppliers offering factory acceptance testing (FAT) or video-based commissioning add verification value.

Transaction Security Protocols

Utilize secure payment mechanisms such as escrow services for initial transactions. Analyze historical order data, focusing on reorder rates as an indicator of customer satisfaction. Conduct sample testing to validate rotational precision, load capacity, and integration ease before scaling procurement.

What Are the Best CNC Rotary Axis Distributor Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range | Customization Options | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jinan Camel CNC Machinery Co., Ltd. | Jinan, Shandong | US $520,000+ | 98% | ≤2h | 16% | 4–6 axis routers, rotary configurations | Spindle, table, cooling, control system | 1 set |

| Jinan Spower Machinery Technology Co., Ltd. | Jinan, Shandong | US $180,000+ | 100% | ≤2h | 54% | 5-axis ATC, heavy-duty rotary systems | Tool changer, spindle drive, safety systems | 1 set |

| Jinan TechPro CNC Equipment Co., Ltd. | Jinan, Shandong | US $670,000+ | 100% | ≤2h | 33% | 4-axis, mini 6090, 1325 rotary models | Worktable, dust aspiration, ATC, cad/cam | 1 set |

| Shenzhen Liyang Engraving Equipment Co., Ltd. | Shenzhen, Guangdong | US $10,000+ | 90% | ≤6h | <15% | Rotary tables, 4th/5th axis modules | Limited—component-level customization | 1 piece/set |

| Shandong Jx Auto Cnc Machinery Co., Ltd | Shandong | US $250,000+ | 100% | ≤4h | 50% | 4–5 axis routers with rotary integration | Spindle power, head count, configuration | 1–30 sets |

Performance Analysis

Jinan-based suppliers dominate both scale and responsiveness, with 80% maintaining sub-4-hour response times and full CE/ISO-aligned production practices. Jinan Spower and Shandong Jx demonstrate high reorder rates (54% and 50%), signaling strong post-sale reliability and system durability. Jinan TechPro leads in export volume (US $670,000+ online revenue), supported by extensive customization options including automatic tool change and dust management systems. In contrast, Shenzhen Liyang focuses on modular rotary components at lower price points, suitable for retrofitting smaller CNC setups, though with limited system integration support. For turnkey solutions requiring precision rotary indexing and industrial-grade durability, suppliers with in-house R&D, proven ATC implementation, and documented quality control processes are recommended.

FAQs

How to verify CNC rotary axis supplier credibility?

Audit certifications (CE, ISO 9001), request facility videos demonstrating assembly and testing procedures, and review transaction histories for consistent on-time delivery. Prioritize suppliers with third-party trade assurance coverage and verifiable customer references in your region.

What is the typical lead time for customized rotary axis systems?

Standard configurations ship in 20–30 days. Custom builds involving servo integration, specialized control panels, or dual-spindle setups require 35–50 days, including pre-shipment testing. Air freight reduces delivery to 5–7 days but increases cost significantly.

Can suppliers provide rotary axis units for machine retrofitting?

Yes, several suppliers offer standalone 4th/5th axis rotary tables compatible with common CNC controllers. Confirm interface compatibility (pulse signal, encoder feedback) and mounting dimensions prior to ordering. Shenzhen Liyang specializes in retrofit kits priced between $150–$400 per unit.

Is customization available for spindle type and worktable design?

Most leading suppliers support customization of spindle power (3–8kW), cooling method (air/water), and worktable type (T-slot, vacuum, oscillating knife). Vacuum tables enhance non-metallic material handling, while T-slot designs suit heavier metal fixtures.

What are common packaging and export practices?

Machines are typically crated in seaworthy plywood with foam padding and moisture barriers. Suppliers provide packing lists, COO certificates, and bill of lading documentation. Confirm whether installation guides, wiring diagrams, and control software are included in the shipment.