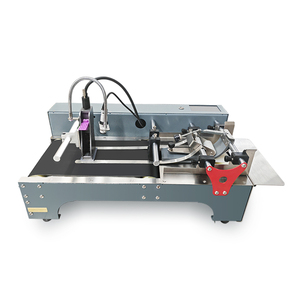

Coding Printer Machine

CN

CN

About coding printer machine

Where to Find Coding Printer Machine Suppliers?

China leads global production of coding printer machines, with concentrated manufacturing hubs in Guangdong, Zhejiang, and Hubei provinces. Shenzhen and Guangzhou in Guangdong province host advanced electronics and industrial printing clusters, leveraging integrated supply chains for microcontrollers, ink delivery systems, and portable power modules. These regions support rapid prototyping and scalable production, particularly for handheld continuous inkjet (CIJ) and thermal inkjet (TIJ) technologies.

Zhejiang’s Hangzhou and Ningbo areas specialize in precision electromechanical equipment, offering cost-efficient assembly lines for desktop and online batch coding systems. Hubei, particularly Wuhan, has emerged as a center for mid-tier industrial automation, balancing performance and affordability for small to medium packaging operations. These regional ecosystems enable vertical integration—combining PCB fabrication, nozzle calibration, and software programming—within compact geographic zones, reducing component lead times by 25–40% compared to offshore alternatives.

Suppliers in these clusters typically operate under lean manufacturing models, supporting MOQs as low as one unit for standard configurations. Average monthly output ranges from 1,000 to 5,000 units per facility, with lead times averaging 15–25 days for bulk orders. Export-ready infrastructure ensures compliance with international shipping standards, particularly for CE-marked models destined for European and North American markets.

How to Choose Coding Printer Machine Suppliers?

Adopt structured evaluation criteria to mitigate sourcing risks and ensure technical alignment:

Technical Compliance & Quality Assurance

Confirm adherence to ISO 9001 quality management standards as a baseline. For regulated industries (pharmaceuticals, food & beverage), prioritize suppliers providing CE certification and documentation on ink chemical composition (e.g., solvent-based vs. water-based, RoHS compliance). Verify print resolution capabilities (measured in dpi) and maximum print height (typically 12.7mm–25.4mm) against application requirements.

Production & Customization Capacity

Assess supplier flexibility through the following indicators:

- Minimum factory area of 2,000m² indicating established production capacity

- In-house R&D teams capable of firmware customization and multi-language interface development

- Support for variable data printing (VDP), including QR codes, GS1 barcodes, and database integration

- Customizable elements: print head configuration, battery type, housing material, and labeling options

Cross-reference product listings with reorder rates above 15% and on-time delivery exceeding 95% to validate operational reliability.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services that release funds upon inspection. Prioritize suppliers offering sample testing with return policies or partial reimbursement. Evaluate responsiveness—target ≤3-hour average reply time—and confirm availability of technical documentation, including user manuals, maintenance guides, and troubleshooting videos. Post-purchase support should include firmware updates and consumables (ink cartridges, cleaning solvents) supply continuity.

What Are the Best Coding Printer Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Incode Marking Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $500,000+ | 95% | ≤4h | 32% | Yes (print head, ink, language, packaging) | 1 set |

| Zhejiang Lianteng Intelligent Equipment Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $370,000+ | 97% | ≤6h | 17% | Yes (handheld design, logo, label) | 1 set |

| Shenzhen Wutong Technology Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $230,000+ | 95% | ≤2h | <15% | Yes (color, size, graphic) | 1 piece |

| Hangzhou Antian Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $80,000+ | 72% | ≤4h | <15% | Yes (material, label, logo) | 1 piece |

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | N/A | US $40,000+ | 96% | ≤3h | <15% | Limited (standard models) | 1 set |

Performance Analysis

Guangzhou Incode stands out with the highest reorder rate (32%) and extensive customization depth, supporting complex integrations like multi-head CIJ systems and two-dimensional code generation. Zhejiang Lianteng achieves strong reliability with a 97% on-time delivery rate and flexible single-unit ordering, ideal for pilot deployments. Shenzhen Wutong excels in responsiveness (≤2h) and low minimum order thresholds, catering to startups and niche applications. Hangzhou Antian, despite lower delivery performance (72%), offers competitive pricing and basic personalization. Wuhan Willita maintains solid service levels but focuses primarily on standardized inkjet and sealing equipment, limiting advanced coding features.

FAQs

How to verify coding printer machine supplier reliability?

Cross-validate ISO and CE claims through official certification databases. Request test reports on print adhesion, ink drying time, and resistance to smudging under real-world conditions. Analyze transaction history, focusing on consistent on-time delivery (>95%) and verifiable customer feedback regarding durability and technical support.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Customized units requiring firmware adjustments or special nozzles may take 20–30 days. Air freight adds 5–10 days for international delivery. Some suppliers offer free samples contingent on subsequent bulk orders (e.g., minimum 5 units).

Can suppliers ship coding printers worldwide?

Yes, most manufacturers support global logistics via air or sea freight. Confirm Incoterms (FOB, CIF) and ensure compliance with destination regulations, especially for lithium batteries and chemical inks. Full container loads benefit from consolidated shipping discounts, reducing per-unit transportation costs by up to 35%.

Do suppliers provide free samples?

Policies vary. Established suppliers may waive fees for qualified buyers committing to volume purchases. Otherwise, expect to cover 30–60% of unit cost for sampling, often redeemable against future orders. Portable models typically incur lower sample charges than industrial-grade systems.

How to initiate customization requests?

Submit detailed specifications: desired print height, line count, character set (including non-Latin scripts), connectivity (Bluetooth/Wi-Fi), and environmental rating (IP protection). Reputable partners respond with engineering proposals, 3D renderings, or functional prototypes within 5–7 business days.