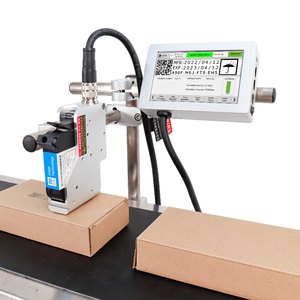

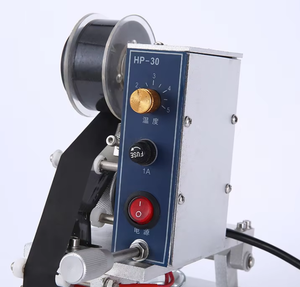

Coding Machine

Top sponsor listing

Top sponsor listing

About coding machine

Where to Find Coding Machine Suppliers?

China remains the global epicenter for coding machine manufacturing, with key supplier clusters concentrated in industrial hubs such as Zhejiang, Hubei, and Henan. These regions host vertically integrated production ecosystems specializing in inkjet, thermal transfer, and laser marking technologies. Proximity to component suppliers—ranging from printheads to control systems—enables rapid assembly and cost-efficient scaling. The Yangtze River Delta, particularly Shanghai and Ningbo, supports agile supply chains with logistics networks that reduce export lead times by 15–25% compared to non-specialized regions.

Manufacturers in these zones leverage mature infrastructure for both standard and customized coding solutions, serving industries including food & beverage, pharmaceuticals, and consumer goods. Average monthly output per facility ranges from 300 to 1,500 units depending on automation level, with many suppliers operating clean-room environments for precision assembly. Localized access to raw materials such as solvent-based inks, solid ribbons, and stainless-steel housings contributes to a 20–30% cost advantage over Western counterparts. Buyers benefit from flexible MOQs, often starting at single-unit orders for portable models, while conveyor-integrated systems typically require 5+ units.

How to Choose Coding Machine Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international standards such as CE for European markets and RoHS for hazardous substance restrictions. For integration into automated lines, verify compatibility with common industrial protocols (e.g., RS-485, Ethernet/IP). Request documentation on nozzle durability, ink adhesion testing, and resistance to environmental factors like humidity or temperature fluctuations.

Production Capability Audits

Assess core competencies through objective metrics:

- Facility size exceeding 2,000m² indicates capacity for batch production

- In-house R&D teams signal innovation capability for custom configurations

- On-site testing labs for print quality validation under real-world conditions

Cross-reference on-time delivery rates (target ≥94%) and response times (ideally ≤4 hours) as proxies for operational reliability.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk. Prioritize suppliers with transparent transaction histories, including verifiable reorder rates and dispute resolution records. Conduct sample testing to evaluate print clarity, drying time, and substrate adhesion before full-scale procurement.

What Are the Best Coding Machine Suppliers?

| Company Name | Location | Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Xinxiang New Bell Information Materials Co., Ltd. | Henan, CN | Custom Manufacturer | Stamping Foil Coding Machines, Inkjet Printers, Sealing Machines | US $100,000+ | 97% | ≤1h | 16% | Yes |

| Wuhan Xiantong Technology Co., Ltd. | Hubei, CN | - | Inkjet Printers, Laser Marking Machines, Printing Machinery Parts | US $160,000+ | 100% | ≤5h | 21% | No |

| Yiwu Jeta International Trading Co,. Ltd. | Zhejiang, CN | Multispecialty Supplier | Solid-ink Coding Machines, Batch Date Printers | US $220,000+ | 100% | ≤4h | <15% | Yes |

| Zhongshan Wise Print Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | TIJ Handheld Coders, Mini Conveyor Coders | US $120,000+ | 94% | ≤4h | <15% | Yes |

| Shanghai Youmu Technology Co., Ltd. | Shanghai, CN | - | TIJ Inkjet Printers, Hand Jet Printers | US $10,000+ | 91% | ≤1h | <15% | No |

Performance Analysis

Wuhan Xiantong and Yiwu Jeta lead in fulfillment reliability with perfect on-time delivery records, indicating robust production planning. Yiwu Jeta stands out with the highest online revenue (US $220,000+), suggesting strong market penetration and volume scalability. Custom-focused manufacturers like Xinxiang New Bell and Zhongshan Wise Print offer tailored solutions for color, material compatibility, and graphic logo printing—critical for brand-sensitive applications. However, lower reorder rates (<15%) among some suppliers may reflect competitive pricing rather than long-term customer retention. Shanghai Youmu, despite fast response times, has limited revenue transparency and below-average delivery performance, warranting due diligence for high-volume contracts.

FAQs

How to verify coding machine supplier reliability?

Cross-check claimed certifications (CE, ISO) with official databases. Request evidence of product compliance testing, including electrical safety and EMC reports. Evaluate supplier credibility through verified transaction data, customer reviews focused on after-sales support, and responsiveness during technical inquiries.

What is the average sampling timeline?

Standard handheld or benchtop coders can be sampled within 7–10 days. Customized models requiring software integration or specialized nozzles take 15–25 days. Add 5–7 days for international air shipping. Some suppliers offer digital proofing via printed samples sent electronically for approval.

Can suppliers ship coding machines worldwide?

Yes, most established manufacturers support global exports with FOB, CIF, or DDP terms. Confirm inclusion of necessary documentation (commercial invoice, packing list, certificate of origin) and compliance with import regulations for electronic equipment in destination markets.

Do manufacturers provide free samples?

Free samples are uncommon for high-value units but may be offered for entry-level models if followed by bulk orders (typically 10+ units). Sample fees are often credited toward future purchases. Portable coders priced under $300 usually incur a nominal charge covering handling and freight.

How to initiate customization requests?

Submit detailed specifications including desired print height (e.g., 10–50mm), substrate type (plastic, metal, cardboard), message content (date, batch, barcode), and environmental conditions. Reputable suppliers will respond with technical feasibility assessments, CAD drawings, or video demonstrations within 72 hours.