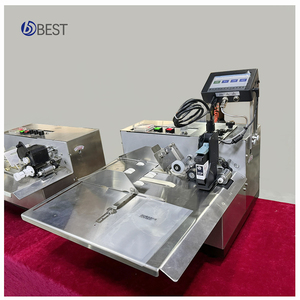

Sepack Coding Machine

About sepack coding machine

Where to Find Sepack Coding Machine Suppliers?

China remains the central hub for coding machine manufacturing, with key industrial clusters in Shanghai, Henan, and Zhejiang provinces driving innovation and production efficiency. Shanghai and surrounding Yangtze River Delta regions host advanced automation firms specializing in digital inkjet and laser coding systems, leveraging proximity to semiconductor and electronics supply chains. Meanwhile, Henan province has emerged as a cost-competitive center for mechanical and semi-automatic coding equipment, supported by mature packaging machinery ecosystems and streamlined logistics networks.

These regional hubs enable vertically integrated production, combining precision engineering, electronics assembly, and software development within compact geographic zones. This integration reduces component lead times and supports rapid prototyping. Buyers benefit from scalable output—facilities routinely handle MOQs from 1 set to full container loads—with typical delivery windows of 15–30 days for standard models. Localized sourcing of motors, nozzles, and control systems contributes to 20–35% cost advantages over Western-built alternatives, while maintaining compatibility with international production line standards.

How to Choose Sepack Coding Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Equipment Type

Confirm adherence to CE marking for electrical safety and EMC directives, particularly for inkjet and laser systems operating in regulated environments (food, pharma, medical devices). Differentiate between machine types: solid ink roll coders (e.g., MY-380F series) suit high-speed carton lines; hot-stamp coders (HP241 variants) are ideal for film and foil; CO₂ laser coders serve permanent date/lot marking on rigid plastics and metals. Validate nozzle durability, print resolution (minimum 200 dpi), and compatibility with production line speeds (up to 200 m/min).

Production Capability Verification

Assess core manufacturing competencies through available indicators:

- Facility scale inferred from product range and listing volume (e.g., suppliers with 100+ packaging machine listings indicate established operations)

- In-house R&D capacity evidenced by customization options (QR code generation, multi-line printing, digital interface upgrades)

- Integration of quality-critical subsystems such as ink delivery, heating elements, and motion control

Cross-reference online revenue metrics and reorder rates as proxies for market acceptance and after-sales reliability.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as trade assurance or escrow services, especially for first-time engagements. Prioritize suppliers with documented on-time delivery performance (target ≥94%) and sub-6-hour response times to ensure post-purchase support. Request sample units to verify print clarity, alignment accuracy, and material adhesion under real-world conditions before scaling orders.

What Are the Best Sepack Coding Machine Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options |

|---|---|---|---|---|---|---|

| Shanghai Demac Machinery Equipment Co., Ltd. | Coding Machines (190) | US $80,000+ | 100% | 47% | ≤6h | Not specified |

| Henan Best Packing Machine Co., Ltd. | Multi-Function Packaging Machines (1033) | US $210,000+ | 94% | 21% | ≤2h | Color, size, QR, logo, packaging |

| Yiwu Jeta International Trading Co,. Ltd. | Coding Machines (not listed) | US $220,000+ | 100% | <15% | ≤4h | Color, size, logo, label |

| Dongguan Sammi Packing Machine Co., Ltd. | Multi-Function Packaging Machines (1033) | US $50,000+ | 90% | 29% | ≤2h | Not specified |

| Changzhou Friendpack Equipment Co., Ltd. | Filling Machines (173) | US $50,000+ | 94% | <15% | ≤2h | Not specified |

Performance Analysis

Shanghai Demac stands out with a 100% on-time delivery record and a strong focus on coding-specific equipment, supported by a 47% reorder rate—indicating high customer retention. Henan Best and Dongguan Sammi offer broad packaging system portfolios, suggesting integration capabilities for turnkey lines, though their lower reorder rates may reflect higher market competition. Yiwu Jeta demonstrates robust transaction volume (US $220,000+ online revenue) and perfect delivery performance despite limited reorder data, positioning it as a reliable option for standardized coding units. Suppliers with declared customization capabilities (Henan Best, Yiwu Jeta) provide flexibility for brand-specific coding formats, including QR codes and graphical logos, which is critical for traceability and anti-counterfeiting applications.

FAQs

What certifications should sepack coding machines comply with?

CE certification is essential for export to Europe and many international markets, ensuring compliance with safety, electromagnetic compatibility, and environmental standards. For food and pharmaceutical applications, verify that materials in contact with products are FDA-compliant or meet local regulatory requirements. While ISO 9001 is not explicitly stated in supplier data, prioritize vendors who reference quality management systems in their profiles.

What is the typical minimum order quantity (MOQ)?

The standard MOQ across suppliers is 1 set or piece, allowing low-volume procurement for testing and small-scale deployment. Some specialized configurations, such as large-format can coding lines, may require higher MOQs (e.g., 5 cases), as seen with Changzhou Friendpack’s tin can coder.

How long does it take to receive a sample?

Sample processing typically takes 7–15 days, depending on model availability and customization needs. Shipping via express courier adds 3–7 days for international delivery. Confirm whether sample fees are refundable against future bulk orders.

Can coding machines be customized for specific production lines?

Yes, multiple suppliers offer customization for print content (date, batch, QR, serial numbers), physical dimensions, mounting interfaces, and communication protocols (RS-232, Ethernet). Suppliers like Henan Best and Yiwu Jeta explicitly list QR code integration and graphic labeling as available upgrades, enabling compliance with serialization mandates.

What are the price ranges for sepack coding machines?

Pricing varies significantly by technology: entry-level electric ribbon coders start at $70–$180; mid-range inkjet systems (MY-380F, HP241) range from $225–$560; high-end CO₂ laser coders exceed $3,700. Price reflects print speed, durability, software features, and integration level. Always compare specifications rather than cost alone to ensure functional suitability.