Collaborative Robots In Manufacturing

CN

CN

CN

CN

About collaborative robots in manufacturing

Where to Find Collaborative Robots in Manufacturing Suppliers?

China has emerged as a dominant hub for collaborative robot (cobot) manufacturing, with key production clusters concentrated in Shandong, Guangdong, and Jiangsu provinces. These regions host vertically integrated ecosystems combining robotics R&D, precision machining, and automation integration. Shandong-based suppliers leverage proximity to heavy industrial zones, enabling rapid prototyping and deployment for palletizing and welding applications. Meanwhile, Guangdong’s Shenzhen-Dongguan corridor offers access to advanced electronics supply chains, supporting high-precision motor and sensor integration critical for safe human-robot collaboration.

The clustering effect reduces component lead times by 20–35% compared to decentralized manufacturing models. Facilities within these zones typically operate under ISO 9001 quality frameworks and maintain in-house capabilities spanning CNC machining, control system programming, and safety certification testing. Buyers benefit from scalable production capacity—standard cobot units are available with MOQs as low as one set—and shorter fulfillment cycles averaging 15–30 days for stock configurations. Custom integrations, including AMR-cobot composites or application-specific end-effectors, can be developed within 45 days depending on complexity.

How to Choose Collaborative Robots in Manufacturing Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Safety Certification

Verify adherence to international safety standards such as ISO/TS 15066 for collaborative operation. CE marking is essential for European market entry, while UL or CSA compliance may be required for North American deployments. Request documentation on force-limited joints, speed monitoring systems, and emergency stop response times. For welding or high-payload applications, confirm payload accuracy (±0.02mm typical) and repeatability specifications.

Production and Engineering Capability

Assess infrastructure maturity through the following indicators:

- Minimum 3,000m² factory area with dedicated assembly and testing bays

- In-house engineering teams capable of custom programming (e.g., ROS, Modbus TCP)

- Integrated testing protocols for 6-axis motion control, vibration resistance, and EMI shielding

Cross-reference online revenue data and reorder rates as proxies for market acceptance and post-sale support effectiveness.

Transaction Security & Procurement Safeguards

Utilize secure payment mechanisms such as escrow services until delivery and functional verification. Prioritize suppliers with documented response times ≤5 hours and 100% on-time delivery records. Conduct virtual audits via facility videos or live calls to validate claims about production scale and quality control processes. Pre-shipment testing should include full-cycle endurance runs and calibration certificate issuance.

What Are the Best Collaborative Robots in Manufacturing Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (USD) | MOQ |

|---|---|---|---|---|---|---|---|---|

| Bremetz (Shandong) Machinery Co., Ltd. | Shandong, CN | Articulated Robots, Packaging Lines, Filling Machines | Not disclosed | 100% | ≤3h | Not available | $1,000–$11,399 | 1 set |

| Shenzhen Era Automation Co., Ltd. | Guangdong, CN | Collaborative Robots, AGV, Material Handling Equipment | US $350,000+ | 100% | ≤2h | 25% | $3,480–$17,900 | 1 set |

| Suzhou JJD Electronic Technology Co., Ltd. | Jiangsu, CN | Collaborative Robots, Articulated Robots, Pneumatic Parts | US $130,000+ | 100% | ≤5h | 60% | $2,980–$7,800 | 1 set |

| Fair Innovation (Suzhou) Robot System Co., Ltd. | Jiangsu, CN | Manipulator, FAIRINO Series Cobots | US $20,000+ | 60% | ≤11h | <15% | $3,488–$8,888 | 1 set |

| Guangdong Borunte Robot Technology Co., Ltd. | Guangdong, CN | Collaborative Robots, Parallel Robots, Electronic Components | US $20,000+ | 75% | ≤3h | 50% | $999–$5,999 | 1 set |

Performance Analysis

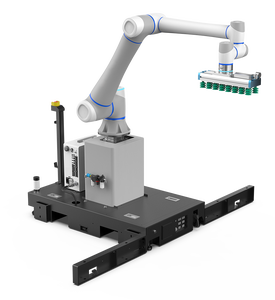

Suzhou JJD leads in customer retention with a 60% reorder rate, indicating strong satisfaction in after-sales service and product reliability. Shenzhen Era Automation stands out in responsiveness (≤2h) and revenue volume, reflecting robust export operations and technical support infrastructure. While Bremetz maintains perfect on-time delivery, its undisclosed reorder metrics limit insight into long-term performance. Fair Innovation and Borunte show moderate delivery consistency (60–75%), suggesting potential bottlenecks in order processing despite competitive pricing. Buyers seeking cost-effective entry-level cobots may consider Borunte’s sub-$1,000 options, whereas those requiring integrated automation solutions should prioritize Shenzhen Era’s composite AMR-cobot systems.

FAQs

How to verify collaborative robot supplier reliability?

Cross-check certifications (ISO, CE) with issuing bodies and request test reports for safety functions like power-off braking and collision detection. Analyze supplier transaction history, focusing on consistent on-time delivery (>95%) and verified customer feedback regarding technical documentation clarity and software update support.

What is the average lead time for collaborative robots?

Standard configurations ship within 15–25 days after order confirmation. Customized units with specialized tooling or communication interfaces require 30–45 days. Air freight adds 5–7 days globally; sea freight takes 25–35 days depending on destination port congestion.

Can suppliers provide robotic arms with pre-installed applications?

Yes, many manufacturers offer turnkey workcells for pick-and-place, palletizing, and welding. Confirm software compatibility (e.g., PLC integration, HMI panels) and whether application programming is included in the quoted price. Some suppliers provide remote commissioning support at no extra cost.

Do collaborative robot suppliers offer free samples?

Sample policies vary. Full-unit sampling is rare due to cost, but suppliers may offer demo units or video-based validation. For pilot testing, expect to pay 50–70% of unit cost, which can be credited toward bulk orders exceeding five units.

How to initiate customization requests for cobots?

Submit detailed requirements including payload (3–10kg typical), reach (500–1,300mm), mounting orientation, and communication protocols (EtherCAT, PROFINET). Reputable suppliers respond with 3D models and control architecture diagrams within 72 hours and deliver prototypes in 4–6 weeks.