Component Assembly Production Service

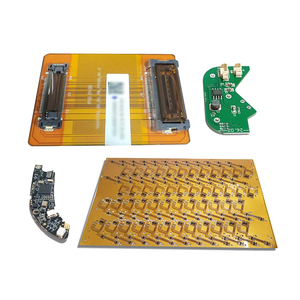

About component assembly production service

Where to Find Component Assembly Production Service Suppliers?

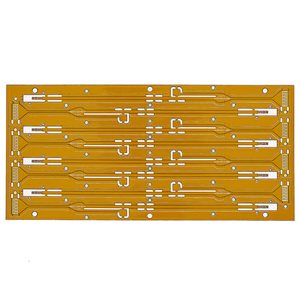

China remains the global epicenter for component assembly production services, with Shenzhen and Shanghai serving as primary hubs due to their advanced electronics manufacturing ecosystems. These regions host vertically integrated facilities specializing in printed circuit board assembly (PCBA), surface mount technology (SMT), and turnkey electronic manufacturing services (EMS). Shenzhen’s supply chain density enables rapid prototyping and low-volume production, with component sourcing lead times averaging 3–5 days. Shanghai-based providers emphasize automation and high-volume throughput, supported by localized access to precision machinery and testing equipment.

The industrial clusters offer economies of scale through co-located PCB fabrication, component distribution, and final assembly operations. This integration reduces logistics overhead and accelerates time-to-market, with standard PCBA lead times ranging from 7 to 14 days. Buyers benefit from flexible production models—ranging from one-off prototypes to mass production—supported by mature quality management systems and export compliance frameworks. Cost efficiencies are further enhanced by competitive labor rates and scalable infrastructure, enabling unit pricing as low as $0.38 for basic assemblies.

How to Choose Component Assembly Production Service Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical and Quality Compliance

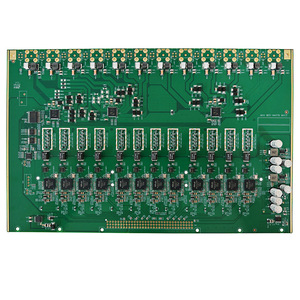

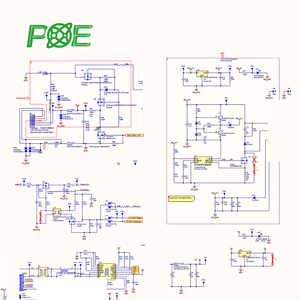

Verify adherence to IPC-A-610 Class 2 or Class 3 standards for electronic assemblies. Look for evidence of RoHS and ISO 9001 compliance as baseline indicators of process control. Suppliers should provide documentation for solder paste inspection (SPI), automated optical inspection (AOI), and in-circuit testing (ICT) protocols. For regulated industries (medical, automotive), confirm alignment with IATF 16949 or ISO 13485 where applicable.

Production Capability Assessment

Evaluate key operational parameters:

- Minimum order quantity (MOQ): Ranges from 1 to 6 pieces; lower MOQs support prototyping and NPI phases

- Monthly production capacity: Inferred from facility scale and automation level; high-output lines handle >50,000 units/month

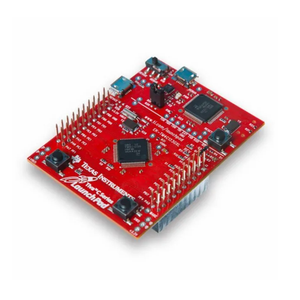

- In-house SMT lines with pick-and-place machines capable of handling 01005 components and BGA packages

- Turnkey service availability, including component sourcing, kitting, and final box build

Cross-reference delivery performance metrics—on-time delivery rates exceeding 98% indicate reliable scheduling and supply chain resilience.

Procurement and Risk Mitigation

Prioritize suppliers offering transparent pricing structures and sample validation options. Confirm customization capabilities for material specifications (e.g., FR4 thickness, solder mask color), silkscreen labeling, and packaging formats. Utilize incremental engagement—start with prototype orders—to assess quality consistency before scaling. Insist on clear IP protection agreements when sharing design files.

What Are the Best Component Assembly Production Service Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Typical MOQ | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Yuetong Electronics Limited | Shenzhen, CN | US $210,000+ | 100% | ≤3h | 44% | Yes | 1 piece | $0.38–6.50 |

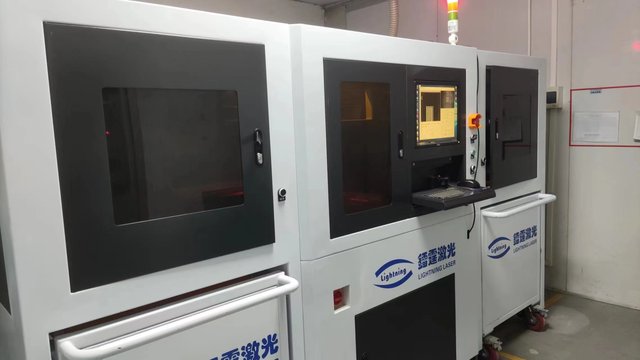

| Morel Equipments Co., Ltd. | Unknown, CN | US $820,000+ | 100% | ≤1h | 50% | Yes | 1 set | $14,999–50,000 |

| Jieliang Electronic Technology Shanghai Co., Ltd. | Shanghai, CN | - | 100% | ≤5h | - | No data | 6 pieces | $1.96–35.20 |

| Toptek Pcb Co., Limited | Unknown, CN | US $1,000+ | 100% | ≤2h | 100% | No data | 1 piece | $1.00–11.80 |

| Shenzhen Wanfeng Technology Co., Ltd. | Shenzhen, CN | US $1,500,000+ | 100% | ≤1h | 27% | Yes | 1–2 pieces | $0.95–6.50 |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and customization flexibility, with Shenzhen Wanfeng Technology leading in online transaction volume (US $1.5M+) and sub-one-hour response times. Morel Equipments distinguishes itself as a capital equipment provider, offering high-speed SMT machines rather than assembly services, indicating a niche focus on production line infrastructure. Toptek Pcb Co., Limited exhibits perfect reorder rate performance (100%), suggesting strong client retention despite limited revenue visibility. Jieliang Electronic operates with higher MOQs (6 pieces), aligning with mid-volume production strategies. All listed suppliers maintain 100% on-time delivery records, underscoring reliability in fulfillment. Buyers seeking full turnkey solutions should prioritize companies advertising engineering consultation, part substitution, and cloning services.

FAQs

How to verify component assembly service reliability?

Request documented quality control procedures, including AOI, X-ray inspection for void analysis, and functional testing reports. Validate certifications through official registries and conduct virtual audits via live video tours of SMT and reflow stations. Analyze transaction history for consistent order completion and customer feedback on defect resolution.

What is the typical lead time for PCBA orders?

Standard turnaround ranges from 7 to 14 days for small batches (1–100 units). Quick-turn services can deliver within 3–5 days at a premium. Lead times extend to 3–4 weeks for complex boards requiring multi-layer stacking, impedance control, or specialized finishes like ENIG.

Can suppliers source components globally?

Yes, most turnkey providers manage component procurement across Asia-Pacific markets, leveraging established relationships with distributors and authorized dealers. However, buyers must specify preferred brands or approved vendor lists (AVLs) to avoid counterfeit parts. Expect additional lead time for backordered or obsolete components.

Do manufacturers support DFM/DFA reviews?

Reputable suppliers offer free Design for Manufacturing (DFM) and Design for Assembly (DFA) analysis prior to production. This includes footprint validation, solder mask clearance checks, and panelization optimization. Confirm this service is provided before releasing Gerber files and BOMs.

Are samples available before bulk production?

Sample assemblies are typically offered at quoted rates, often covering material and setup costs. Some suppliers waive fees for subsequent bulk orders. Sample quantities range from 1 to 5 units, with detailed test reports provided upon request.