Component Production

Top sponsor listing

Top sponsor listing

CN

CN

1/19

1/19

CN

CN

1/14

1/14

1/25

1/25

1/34

1/34

1/44

1/44

1/24

1/24

CN

CN

1/17

1/17

1/22

1/22

1/16

1/16

1/30

1/30

1/18

1/18

About component production

Where to Find Component Production Line Suppliers?

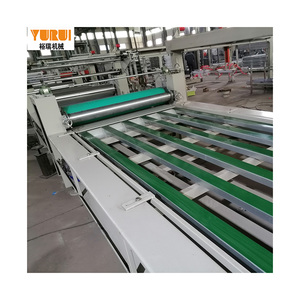

China remains the global epicenter for component production line manufacturing, with key industrial hubs in Guangdong, Shandong, and Hebei provinces driving innovation and scale. The Pearl River Delta region—particularly Shenzhen and Dongguan—hosts advanced electronics-focused suppliers leveraging fully integrated SMT and assembly infrastructure. These clusters benefit from proximity to semiconductor supply chains and automated machinery R&D centers, enabling rapid prototyping and deployment of compact, high-efficiency production systems.

Suppliers in this ecosystem operate within vertically aligned networks where PCB handling, soldering, testing, and final assembly are consolidated under single-source solutions. This integration reduces system integration complexity for buyers and supports modular expansion. Lead times for standard configurations typically range from 20–45 days, with customization extending delivery by 10–15 days depending on control system revisions or material specifications. Buyers gain access to flexible MOQs (as low as 1 set) and cost advantages driven by localized automation component sourcing, achieving up to 25% lower procurement costs compared to EU- or US-based manufacturers.

How to Choose Component Production Line Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer core competencies in electronics production machinery, including SMT placement, reflow soldering, AOI inspection, and conveyor integration. For specialized applications such as automotive or industrial control panels, verify compatibility with IPC-A-610 standards. Demand documentation on PLC programming (Siemens, Mitsubishi, or Allen Bradley platforms), motor control systems, and safety interlocks (CE-certified electrical panels preferred).

Production Infrastructure Assessment

Evaluate the following operational benchmarks:

- Minimum factory area of 2,000m² for dedicated production and testing zones

- In-house engineering teams capable of layout design and workflow optimization

- Availability of pre-commissioned demo units for performance validation

Cross-reference on-time delivery rates (target ≥98%) and response times (≤2 hours) as indicators of operational discipline and customer service capacity.

Quality & Transaction Assurance

Prioritize suppliers with documented quality management systems (ISO 9001 compliance recommended). Where applicable, confirm adherence to RoHS directives for lead-free manufacturing environments. Utilize secure payment frameworks with milestone-based disbursements tied to equipment testing milestones. Pre-shipment inspections should include functional testing of pick-and-place accuracy, conveyor synchronization, and thermal profile stability in reflow ovens.

What Are the Best Component Production Line Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Verified Supplier |

|---|---|---|---|---|---|---|---|

| Shenzhen Extension Electromechanical Co., Ltd. | Electronics Production Machinery, Screen Printers, Welding Equipment | Efficiency improvement, configuration, refurbishment, workshop planning | 100% | 53% | ≤2h | US $120,000+ | Yes |

| Laizhou Taixu New Material Technology Co., Ltd. | Mixing Equipment, Chemical Machines, Cloth Cutting Machines | Core components, turnkey lines for trucks | 100% | 50% | ≤1h | US $40,000+ | No |

| Dongguan Anleji Intelligent Electronics Co., Ltd. | SMT Assembly Lines, Electronic Products Machinery | Desktop SMT lines, small-scale automation | 100% | <15% | ≤1h | US $1,000+ | No |

| Guangzhou Lms Machinery Co., Ltd. | Supermarket Shelf, Metal Bunk Bed Frame Production Lines | Drawing-based customization | 100% | <15% | ≤5h | US $90,000+ | Yes |

| Beijing Huawei Silkroad Electronic Technology Co., Ltd. Hebei Branch | Automatic Assembly Lines, Core Components Manufacturing | Color, material, size, logo, packaging, labeling | 100% | <15% | ≤2h | US $7,000+ | Yes |

Performance Analysis

Shenzhen Extension Electromechanical stands out with the highest reorder rate (53%) and strong revenue volume, indicating consistent customer retention and market trust. Laizhou Taixu excels in responsiveness (≤1h) and offers niche turnkey solutions for industrial sectors beyond electronics. Dongguan Anleji specializes in entry-level SMT lines priced between $3,490–$3,699 per plant, making it a strategic choice for startups or pilot production. Guangzhou Lms targets non-electronic component manufacturing with high-value metal forming systems exceeding $80,000 per set. Beijing Huawei Silkroad provides extensive aesthetic and dimensional customization, suitable for OEM-integrated deployments requiring brand alignment.

FAQs

How to verify component production line supplier reliability?

Validate certifications (ISO 9001, CE), review technical documentation (electrical schematics, PLC code samples), and request video audits of active production floors. Analyze historical transaction data focusing on dispute resolution frequency and after-sales support responsiveness.

What is the typical lead time for customized production lines?

Standard configurations ship within 20–30 days. Customized systems involving new tooling, control logic adjustments, or unique material feeds require 35–50 days. Rush orders may be accommodated with expedited fees (15–25% surcharge).

Do suppliers support global shipping and installation?

Most suppliers offer FOB pricing with optional CIF terms. Full turnkey projects may include remote commissioning support via video guidance. On-site installation and training are typically available at additional cost ($150–$250/day plus travel).

Are samples or demo units available before purchase?

Due to the capital nature of production lines, full-system sampling is uncommon. However, reputable suppliers provide test videos, CAD layouts, and access to operational demo units at their facilities. Component-level samples (e.g., conveyor modules or feeder systems) may be provided upon request.

What level of customization is feasible?

Suppliers support modifications in footprint, speed (PPM), power requirements (110V/220V), and integration interfaces (RS-485, Ethernet/IP). Advanced customization includes HMI language localization, barcode traceability systems, and MES connectivity. Submit detailed process flow diagrams and product dimensions for accurate quoting.