Components Of Production

Top sponsor listing

Top sponsor listing

1/28

1/28

About components of production

Where to Find Production Components Suppliers?

Global manufacturing hubs in China and Bangladesh dominate the supply of production components, offering scalable solutions across diverse industrial sectors. Southern China—particularly Guangdong province—hosts concentrated clusters of precision engineering firms specializing in metal fabrication, injection molding, and CNC machining. These regions benefit from mature supply chains for raw materials such as stainless steel, aluminum, and engineering plastics, enabling cost reductions of 20–30% compared to Western suppliers. Proximity to Shenzhen and Dongguan logistics networks ensures efficient export processing, with average lead times ranging from 15 to 30 days for custom orders.

Bangladesh has emerged as a niche supplier for heavy industrial equipment and marine machinery components, leveraging lower labor costs and specialized shipyard infrastructure. However, most high-precision component sourcing is centered in East Asian manufacturing zones where vertically integrated facilities support rapid prototyping and batch production. Buyers gain access to ecosystems combining design engineering, material sourcing, quality inspection, and packaging—all within compact geographic radii—facilitating agile procurement cycles and reduced time-to-market.

How to Choose Production Components Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Quality Management Systems

Prioritize suppliers with IATF 16949 certification, particularly for automotive or precision mechanical components. This standard ensures adherence to rigorous process controls, defect prevention, and continuous improvement protocols. For general industrial parts, verify ISO 9001 compliance as a baseline indicator of quality assurance. Request documented evidence of in-process inspections, final product testing, and traceability systems.

Production Capacity & Capabilities

Assess core competencies based on available technologies and facility scale:

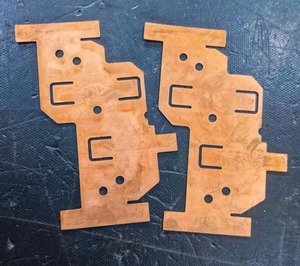

- Sheet metal fabrication: Laser cutting, bending, slitting, and galvanization capabilities for color-coated or corrosion-resistant finishes

- Machining services: CNC lathes, milling, and turning for aluminum, stainless steel, and plastic components (tolerances down to ±0.01mm)

- Plastic mold development: In-house tooling design and injection molding for low-volume to mass production runs

- Customization scope: Ability to modify material type, size, angle, logo imprinting, labeling, and packaging per 2D/3D drawings

Cross-reference stated capabilities with verified performance metrics such as on-time delivery rates (>97%) and reorder frequency to assess reliability.

Procurement Safeguards

Implement risk mitigation strategies including third-party inspection services prior to shipment and secure payment terms via escrow arrangements. Evaluate responsiveness (target ≤5 hours) and communication consistency during initial inquiries. Conduct virtual or on-site audits to validate factory conditions, workforce expertise, and inventory management practices before long-term commitments.

What Are the Best Production Components Suppliers?

| Company Name | Specialization | Verified Supplier Type | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Dongguan Taihe Hardware Products Co., Ltd. | Sheet Metal Fabrication, Electrical Contacts, Springs, Machining Services | Custom Manufacturer | 100% | ≤5h | 48% | US $280,000+ | Laser cutting, bending, slit, material/color/size/logo customization, packaging labels, graphic holes, galvanized finish |

| Xiamen HYM Metal Products Co., Ltd. | Precision Machining, CNC Lathe Parts, Stainless Steel & Aluminum Components | Multispecialty Supplier | 100% | ≤4h | 55% | US $2,600,000+ | Color, material, size, logo, packaging, label, graphic options |

| INTERTECH MACHINERY INCORPORATION | Plastic Mold Making, Injection Molding, Quality Control Services | - | 100% | ≤19h | - | - | Custom mold design, high-accuracy production, low-volume solutions |

| TECHNOCRAT MOULDINGS PVT LTD | Shoe Moulding Machines, Injection Molding Equipment, Brick & Tile Machinery | - | - | ≤3h | - | - | Machine-specific configurations for TPR outsoles, gearbox inserts, single-color injection units |

| M/S OCEAN MARINE SERVICE | Marine Engines, MTU Diesel Engine Components, Boat Engine Parts | - | - | ≤5h | - | - | Supply of new and unused marine machinery with full engine specifications |

Performance Analysis

Dongguan Taihe and Xiamen HYM stand out for their documented quality compliance (IATF 16949), high on-time delivery performance (100%), and strong reorder rates—indicating consistent customer satisfaction. Xiamen HYM’s significant online revenue volume (over US $2.6 million) reflects extensive market penetration and proven scalability in precision metal component manufacturing. INTERTECH MACHINERY focuses on mold development with fixed pricing ($3,500/set), catering to clients needing reliable, repeatable plastic part production. TECHNOCRAT MOULDINGS offers higher-ticket machinery (from $13,000 to $38,000/unit), suggesting specialization in capital equipment rather than discrete components. M/S OCEAN MARINE SERVICE supplies large-scale marine powertrain systems priced between $110,000 and $350,000, targeting niche maritime industries.

FAQs

What are typical MOQs for production components?

Minimum order quantities vary by component type. Precision machined parts may have MOQs as low as 1 piece, while sheet metal batches or molded components typically require 100–500 units. Some suppliers offer prototype services without MOQ for validation purposes.

How long do custom production component orders take?

Standard lead times range from 15 to 30 days after drawing approval. Complex tooling projects (e.g., plastic injection molds) may require 4–6 weeks. Expedited timelines can be negotiated with suppliers maintaining in-house R&D and machining centers.

Can suppliers provide material certifications?

Yes, reputable manufacturers supply mill test certificates for metals and RoHS compliance documentation upon request. Confirm availability during initial technical discussions, especially for regulated industries like automotive or medical devices.

Do suppliers support dropshipping or direct OEM labeling?

Many suppliers offer private labeling, custom packaging, and direct shipment options. Verify these services through the supplier’s tags or direct inquiry, ensuring alignment with brand and logistics requirements.

What payment terms are common in international sourcing?

Standard terms include 30% deposit with balance paid before shipment. Escrow-based transactions are recommended for first-time engagements. High-volume buyers may negotiate longer credit periods after establishing track records.